Description

Product Introduction

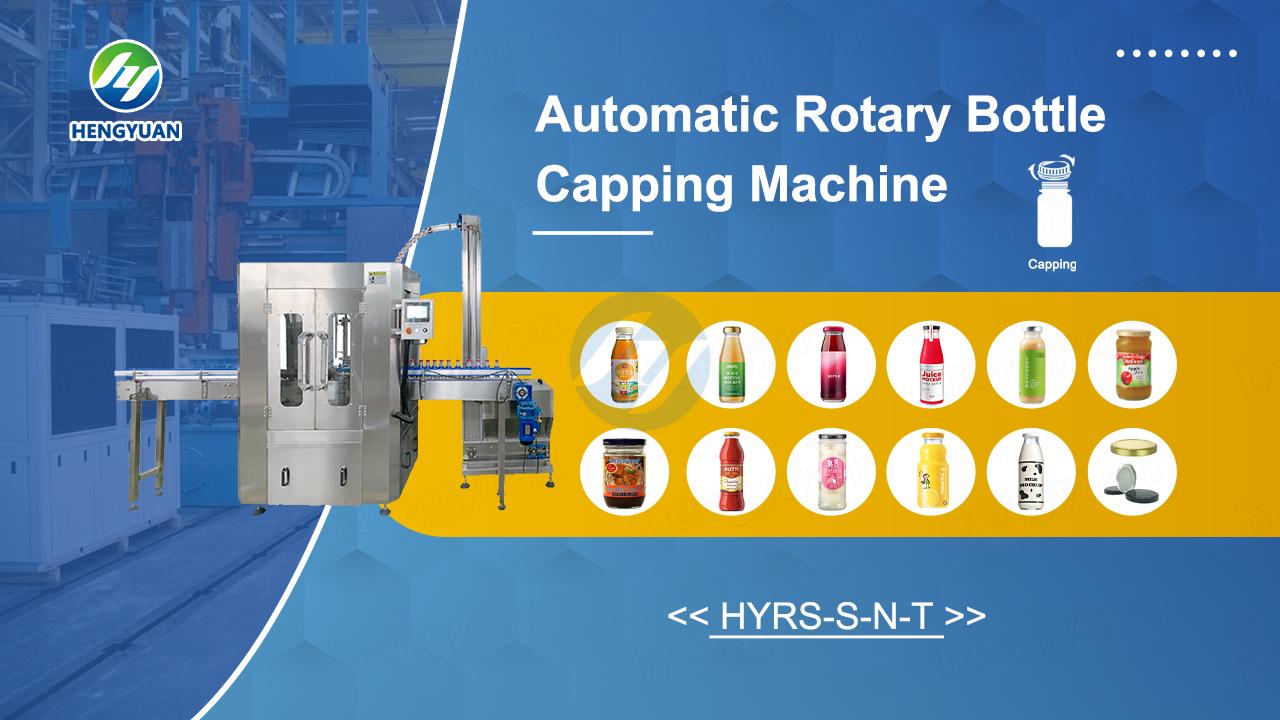

This automatic rotary-type grasping capping machine is designed for the efficient sealing of twist-off tinplate lids. It integrates bottle collection, cap sorting, cap grasping, screw-on capping, and bottle discharge into a single, continuous rotary system. Utilizing a catch-and-position rotary capping mechanism, the machine ensures gentle handling without damaging bottles or caps, delivering high efficiency, excellent sealing quality, stable operation, and wide applicability.The machine is compatible with 3 or 4-groove twist-off tinplate caps and performs automatic rotary sealing on standard glass bottles. Caps are delivered via a scraper plate and securely tightened as bottles rotate through the capping station. Controlled by a PLC system with a touch-screen HMI, the equipment offers intuitive operation and flexible adjustment.

Customizable to match specific bottle and lid dimensions, this capper provides reliable performance, easy operation, and low maintenance. It is widely used in automated packaging lines across the food, beverage, pharmaceutical, and chemical industries, and is particularly suitable for sealing plastic caps on bottles such as mineral water, carbonated drinks, juice beverages, and other similar containers.

Ideal for high-speed production environments, this machine ensures consistent, secure sealing—making it a trusted choice for modern packaging operations.

Product Application

Tin Plate Cap Twist-on Bottle Capping Machine, Twist‑Off Tinplate Lid Sealer,

Juice Glass Bottle Capper, Ketchup & Sauce Glass Bottle Twist‑On Capper,

Food Sauce Glass Bottle Sealing Machine, Drinking Water Bottle Screw Capper,

Glass Bottle Cap Sealer, Milk Glass Bottle Capping System

Technical Parameters

Capping capacity

3000-15000 bottles/hour according to bottle and lid sizes

Capping heads

6, 8, 10, 12pcs

Applicable cap diameter

customized according to caps

Suitable bottle diameter

customized according to bottle sample

Suitable for bottle height

customized according to bottle sample

Total Power

2.0kw

Power supply

AC380V/220V/110V, Single phase or three phased, globally customized

Air pressure

0.4Mpa-0.7Mpa

Machine size

200*100*200cm

Main Features

8 Key Features of the Automatic Rotary Twist-Off Cap Sealing Machine1. Sleek Appearance and High‑Speed Performance

Modern industrial design with quick capping action ensures a high pass rate and smooth operation.

2. Compact and Easily Integrated Structure

Designed with a space‑saving layout and logical connectivity for seamless linkage with upstream and downstream packaging equipment.

3. Premium Brand Components

Built with internationally recognized pneumatic, electrical, and control components to guarantee reliability and long‑term stability.

4. Adjustable Production Speed

Offers flexible output ranging from 3,000 to 15,000 bottles per hour to meet varying production demands.

5. Intelligent Torque Control & Easy Adjustment

Incorporates a smart mechanical torque system for precise cap tightening, along with simple, tool‑free operational settings.

6. Versatile Operation Modes

Functions efficiently as a stand‑alone unit or as part of a fully automated production line.

7. Specialized for Twist‑Off Tinplate Caps

Optimized for secure sealing of 3‑ and 4‑groove twist‑off tinplate lids on glass and compatible plastic bottles.

8. Wide Industry Application

Suitable for food, beverage, pharmaceutical, and chemical packaging lines, offering consistent and reliable capping performance.