HYLP-100A-C Automatic Plastic Dropper Bottle Orienting Machine | Orienter Sorter to Indonesia PT. AGMAC

In 2021, PT. AGMAC, a renowned company based in Indonesia, recognized the need to optimize their production line and improve overall efficiency. To achieve this, they turned to Hengyuan Machinery Co., Ltd. and invested in the HYLP-100A-C Automatic Small Bottle Unscrambler. Little did they know that this decision would not only meet but exceed their expectations, setting the stage for a long-standing partnership and remarkable success.

PT. AGMAC's initial purchase of the HYLP-100A-C was driven by the desire to streamline their operations and eliminate the challenges associated with manual bottle unscrambling. From the moment they received the machine, PT. AGMAC was impressed with the exceptional quality and craftsmanship exhibited by Hengyuan Machinery Co., Ltd. It was evident that the company's commitment to delivering top-of-the-line equipment was unparalleled.

Upon putting the HYLP-100A-C into operation, PT. AGMAC experienced a significant transformation in their production processes. The machine's smooth and fast operation ensured a seamless bottle unscrambling process, eliminating bottlenecks and greatly improving productivity. PT. AGMAC was thrilled with the results and expressed their utmost satisfaction with the performance of the bottle unscrambler.

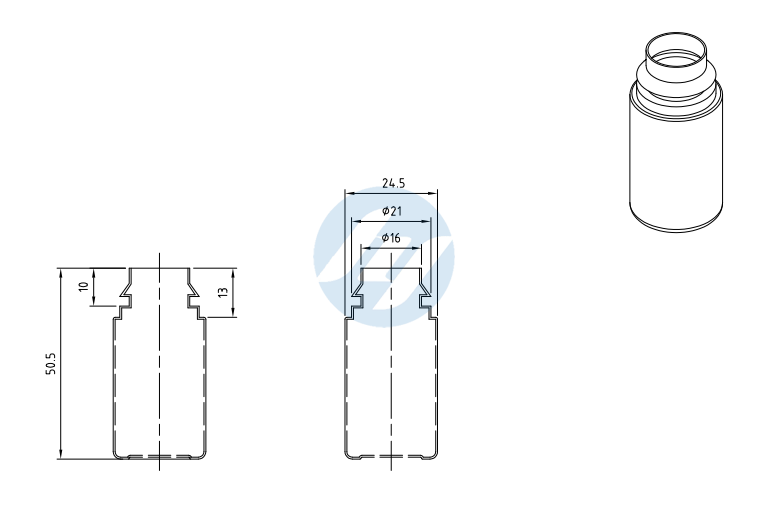

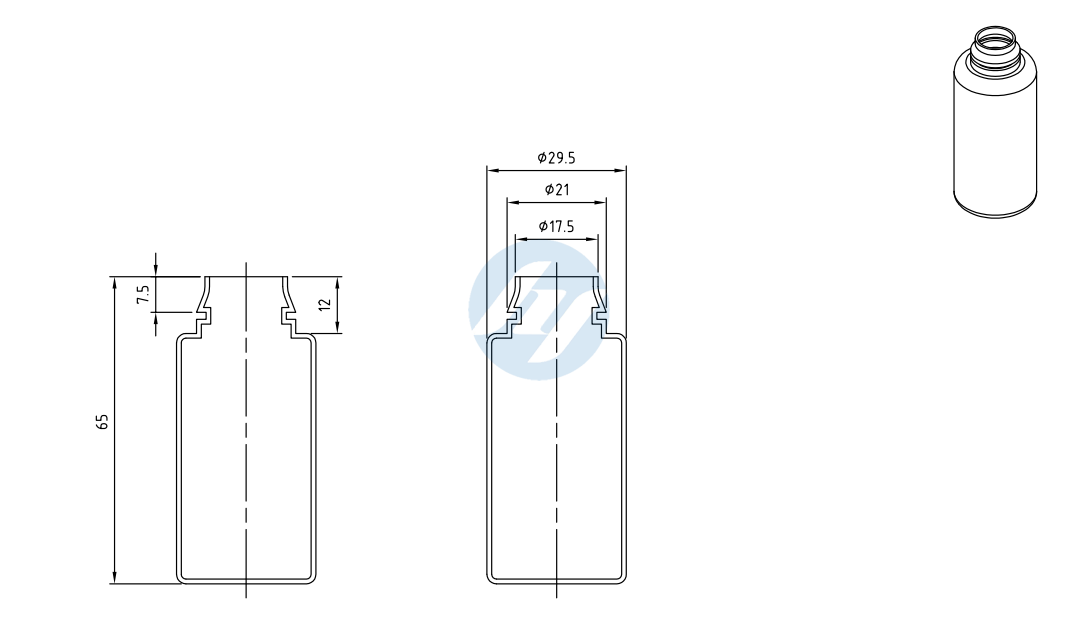

Building on their successful partnership, PT. AGMAC decided to further enhance their production capabilities in 2023. This time, they approached Hengyuan Machinery Co., Ltd. for a bottle orienter to accommodate 15ml and 30ml plastic bottles. Providing bottle samples for customization, PT. AGMAC sought to consolidate their bottle sorting process by utilizing a single machine capable of handling both bottle sizes.

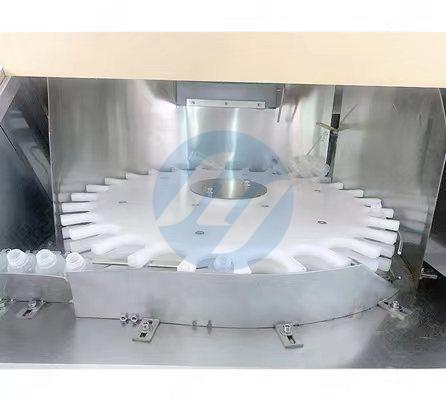

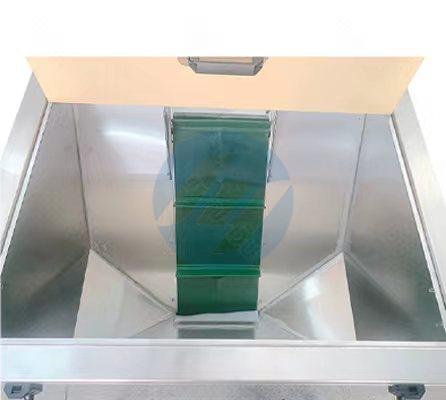

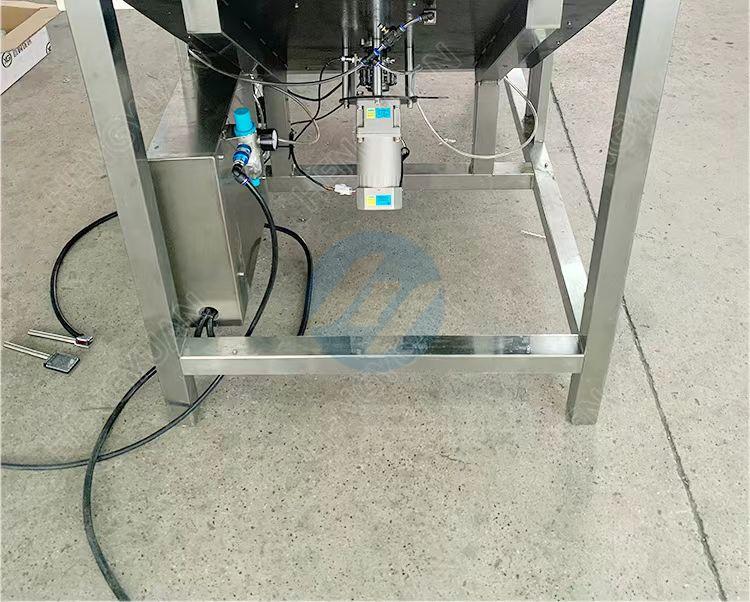

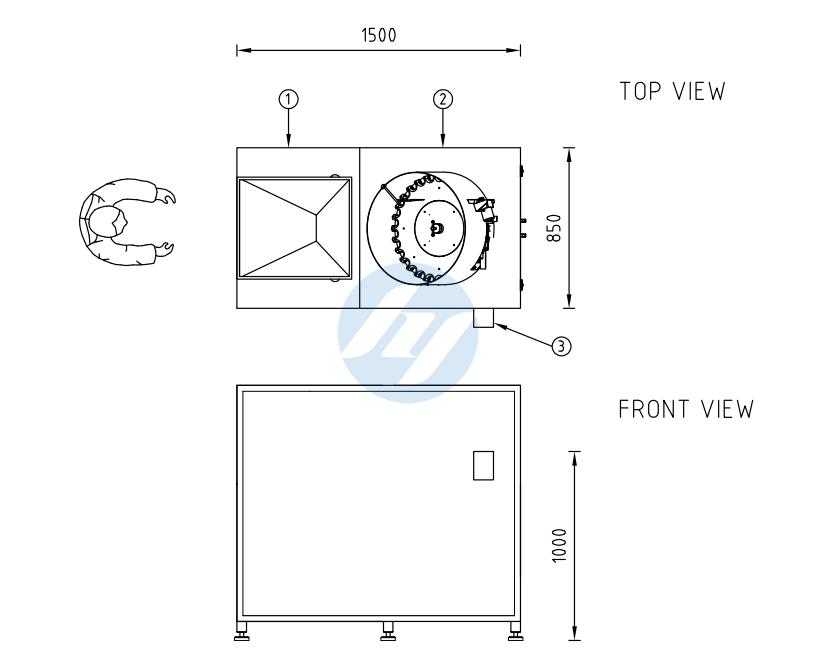

Responding promptly to PT. AGMAC's requirements, Hengyuan Machinery Co., Ltd. embarked on customizing the HYLP-100A-C bottle unscrambler to incorporate two sets of star wheel plates. By carefully installing these plates, the machine would seamlessly sort and orient both 15ml and 30ml plastic bottles. Leveraging their expertise and extensive industry knowledge, Hengyuan Machinery Co., Ltd. navigated the customization process with ease, ensuring a flawless integration of the star wheel plates. Actually, In addition to being applied to bottles of different sizes, this bottle sorting machine can also be used on different products. For example: various sizes of pesticide bottle unscrambler, eye drops bottle unscrambler equipment, etc. At the same time, it can also connect the filling machine and capping machine to form a production line, greatly saving time and labor costs.

Throughout the manufacturing process, Hengyuan Machinery Co., Ltd.'s craftsmen meticulously polished every component, paying close attention to detail to guarantee the machine's smooth operation. The focus on quality and precision ensured that the machine met PT. AGMAC's stringent requirements.

Once the machine was completed, a comprehensive fatigue test was conducted to assess its reliability and performance under real-world conditions. A video recording of the test was shared with PT. AGMAC, allowing them to witness firsthand the machine's exceptional operation and functionality. The customer's satisfaction was further solidified as they were impressed by the bottle unscrambler's seamless performance. With complete satisfaction and confidence in the HYLP-100A-C bottle unscrambler and bottle orienter, PT. AGMAC eagerly awaited the arrival of their customized machine. After completing the final payment, Hengyuan Machinery Co., Ltd. diligently packaged the equipment and coordinated its sea transportation to Indonesia, ensuring a smooth and timely delivery.

The success story of PT. AGMAC and Hengyuan Machinery Co., Ltd. is a testament to the commitment of both parties to deliver high-quality, customized solutions that exceed customer expectations. By investing in the HYLP-100A-C Automatic Small Bottle Unscrambler and the subsequent bottle orienter, PT. AGMAC experienced a remarkable increase in productivity and efficiency, achieving their goal of optimizing their production line.