Description

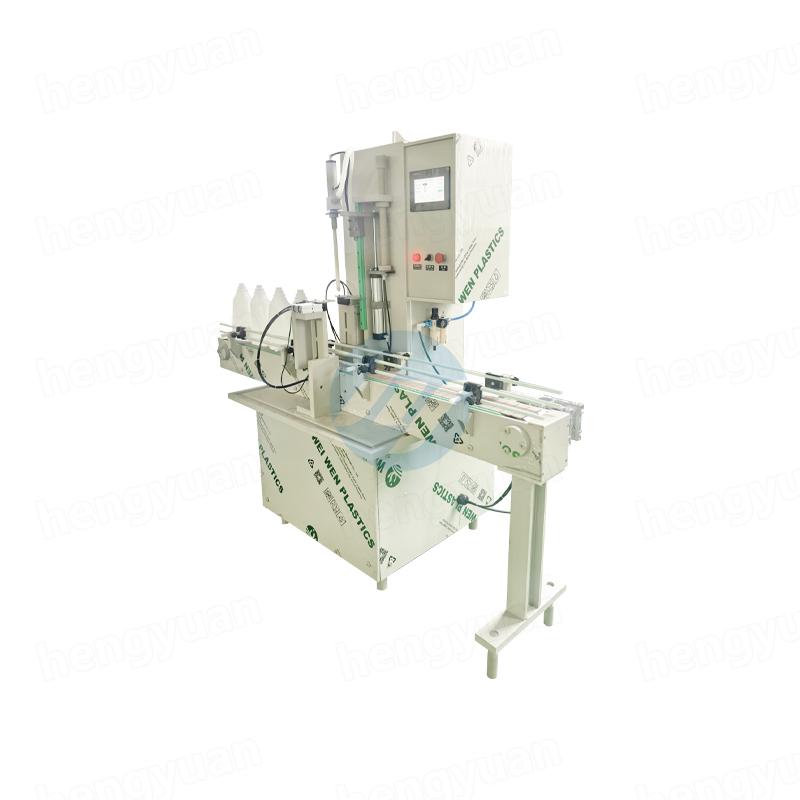

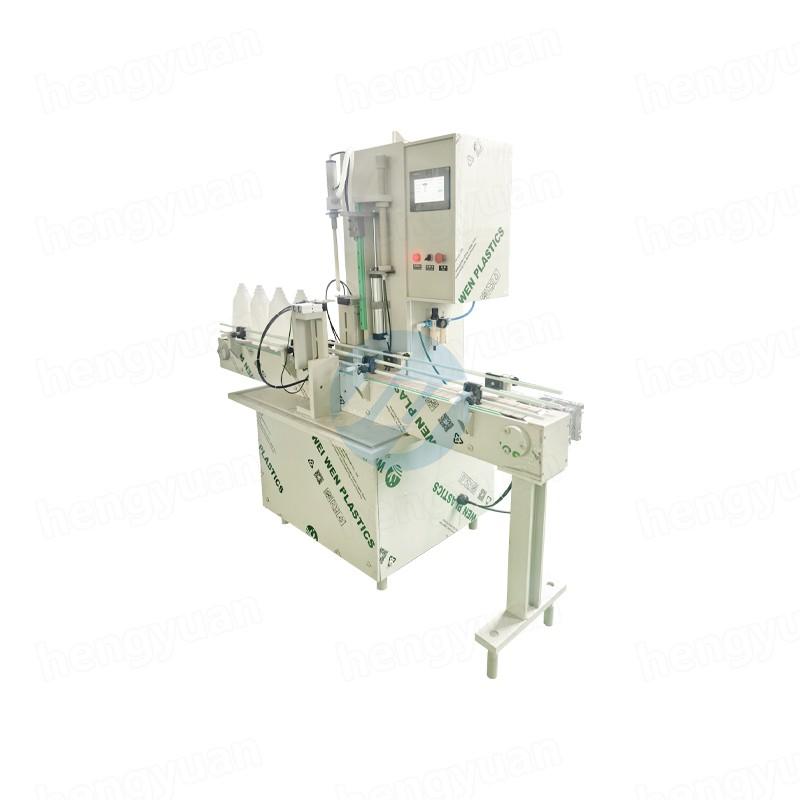

HYGP-A100A Anti-corrosive Gear Pump One Head Filling Machine

Product Introduction

Linear Automatic Anti-corrosive Gear Rotor One Head Pump dosing filling machine is economical filler for different viscous liquid and cream with different bottle or jars. The performance of the product reaches the international leading level. PLC control, servo gear pump dosing, equipped with brand touch screen, smooth operation, no leakage phenomenon, No bottle no filling, automatically control feeding the liquid into machine tank, liquid level is controlled at the same height.

The parameters are adjustable, simple and convenient, and the filling dose can be accurately calibrated, controlled within 0.5% of the filling dose. The machine is made of anti-corrosive PP, beautiful appearance, will not pollute the material, is the best choice of both high viscosity and normal liquid filling.

Bottling Filling Machine is realized by the man-machine dialogue interface under the operation and control of high-speed PLC. It realizes the linear step-less speed regulation transmission through the human-machine dialogue interface, and can adjust the filling capacity arbitrarily.

The filling machine assembly line integrates machine, electricity and gas into one, with unique design, complete functions, stable performance, high quality and beautiful appearance.

Easily dismantle, clean and maintain. The whole machine is safe, environmental, sanitary, adapting to various kinds of working place.

Product Application

Automatic filling machine, bottle filling machine, toilet bowl cleaner filling machine, liquid bleach filling machine, javel liquid filler, sulphuric acid filling machine, 84 disinfectant, filler, sodium hypochlorite disinfectant barrel filling machine, strong acid filling machine, liquid fertilizer filler, HCL solution filler, detergent filling machine, pipeline unclogger filler, oil fume purifier dispenser, kitchen cleaner dispensing machine, disinfectant and stain remover solution filling equipement, etc.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

4) Accurate measurement: adopt servo control system with plastic PEEK gear pump.

5) There is anti-leakage nozzle, prevent the liquid drop on conveyor cause pollution.

6) Convenient adjustment: replacement filling specifications only by setting on touch screen.

7) Wide range of application: unique pump head structure, can transport high viscosity pure materials. (As long as the flow can be filled).

Product Introduction

Linear Automatic Anti-corrosive Gear Rotor One Head Pump dosing filling machine is economical filler for different viscous liquid and cream with different bottle or jars. The performance of the product reaches the international leading level. PLC control, servo gear pump dosing, equipped with brand touch screen, smooth operation, no leakage phenomenon, No bottle no filling, automatically control feeding the liquid into machine tank, liquid level is controlled at the same height.

The parameters are adjustable, simple and convenient, and the filling dose can be accurately calibrated, controlled within 0.5% of the filling dose. The machine is made of anti-corrosive PP, beautiful appearance, will not pollute the material, is the best choice of both high viscosity and normal liquid filling.

Bottling Filling Machine is realized by the man-machine dialogue interface under the operation and control of high-speed PLC. It realizes the linear step-less speed regulation transmission through the human-machine dialogue interface, and can adjust the filling capacity arbitrarily.

The filling machine assembly line integrates machine, electricity and gas into one, with unique design, complete functions, stable performance, high quality and beautiful appearance.

Easily dismantle, clean and maintain. The whole machine is safe, environmental, sanitary, adapting to various kinds of working place.

Product Application

Automatic filling machine, bottle filling machine, toilet bowl cleaner filling machine, liquid bleach filling machine, javel liquid filler, sulphuric acid filling machine, 84 disinfectant, filler, sodium hypochlorite disinfectant barrel filling machine, strong acid filling machine, liquid fertilizer filler, HCL solution filler, detergent filling machine, pipeline unclogger filler, oil fume purifier dispenser, kitchen cleaner dispensing machine, disinfectant and stain remover solution filling equipement, etc.

Technical Parameters

Filling range

50ml-30000ml (customized)

Filling heads

1pc

Filling nozzle outer diameter

Customized according to bottle mouth

Filling accuracy

≤±0.5%

Filling speed

30L/Minute ( Others can be customized)

Control method

Automatic

Buffer Hopper Function (Optional)

Automatic replenishment

Volume of Hopper

≈50L

Working air pressure

0.4-0.8Mpa

Operation voltage

220V/50Hz/1P, customized globally

Electricity consumption

1.5 Kw

Machine size

200*90*170cm

Weight

180Kg

Main Features

1) Simple structure in linear type, easy in installation and maintenance.2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

4) Accurate measurement: adopt servo control system with plastic PEEK gear pump.

5) There is anti-leakage nozzle, prevent the liquid drop on conveyor cause pollution.

6) Convenient adjustment: replacement filling specifications only by setting on touch screen.

7) Wide range of application: unique pump head structure, can transport high viscosity pure materials. (As long as the flow can be filled).

8) Easy to wash: pour clean detergent and water into the equipment and wash it with high-speed circulating water, which is convenient and sanitary.