Description

HYYG-100-C Pail Plastic Lid Pressing-on Capping Machine

Product Introduction

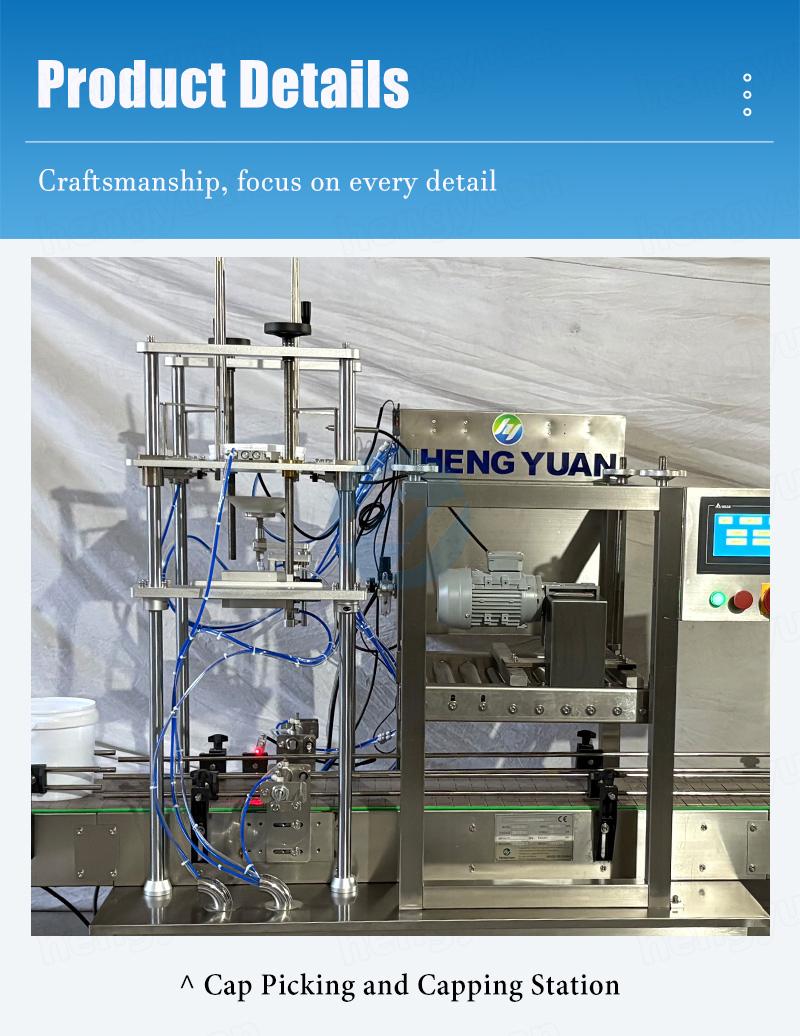

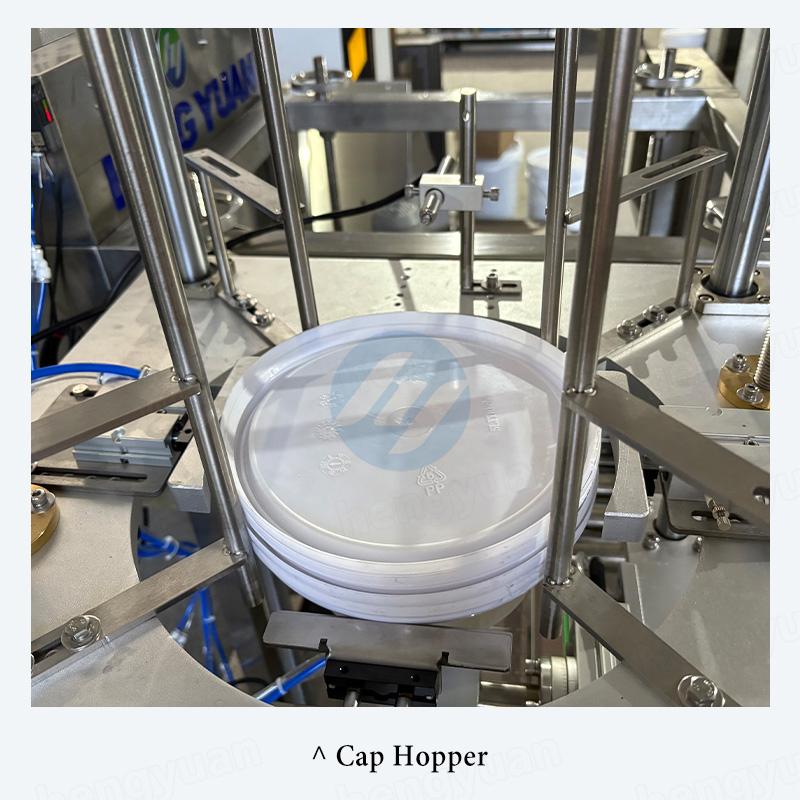

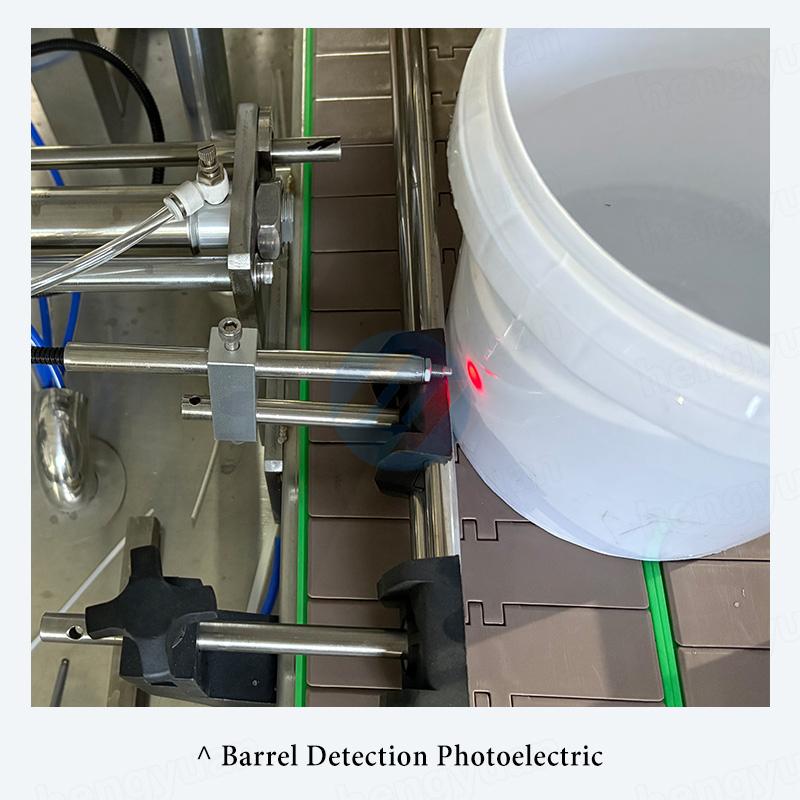

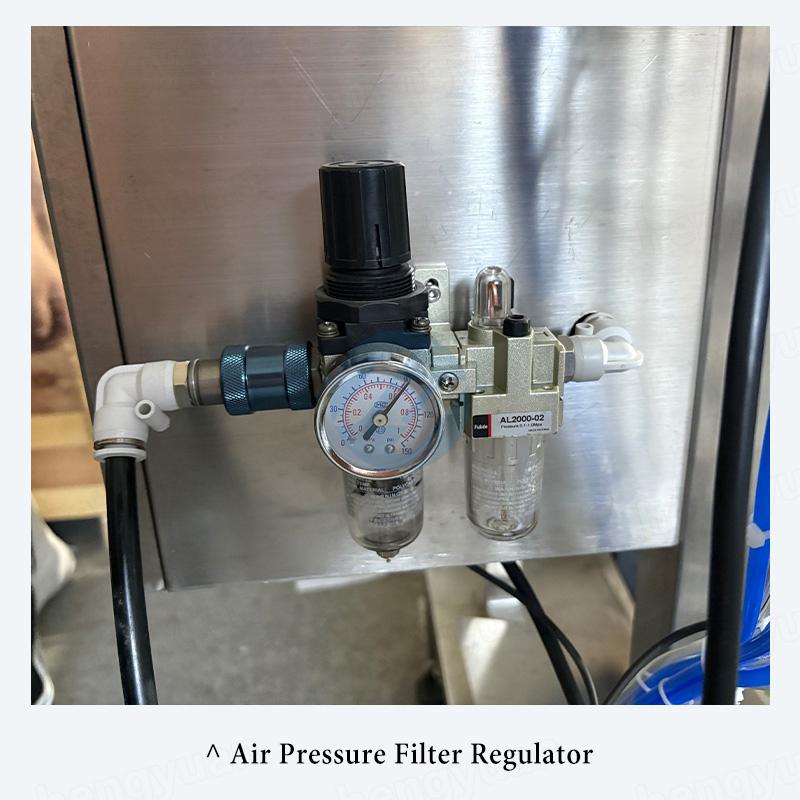

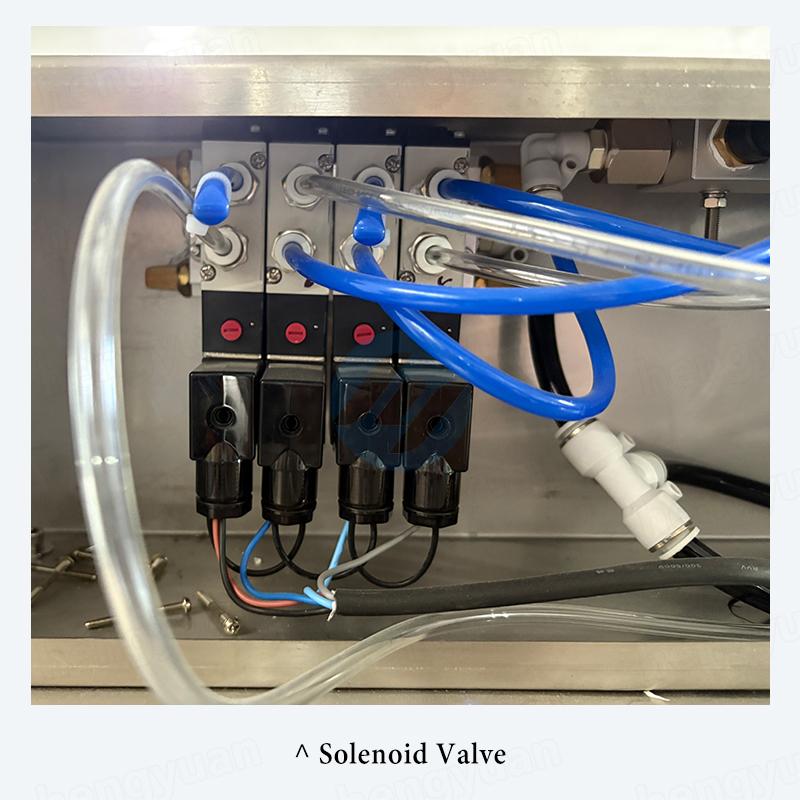

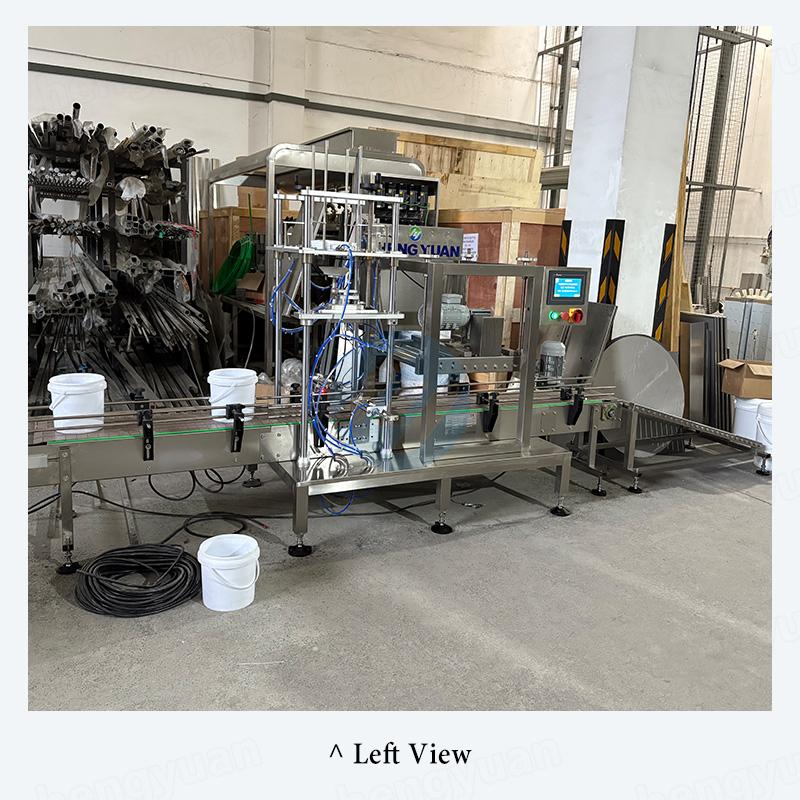

Automatic Lid Placing & Capping Machine for Wide-Mouth Barrels is designed for placing and crimping lids onto wide-mouth barrels. It features a pneumatic system for picking and placing lids, a powered roller pressing mechanism, and a lower chain-plate conveyor. The operation is simple, maintenance is straightforward, and performance is highly reliable.

It is ideally suited for capping large smooth-rim barrels, such as those for lubricating oil and coatings. The process begins by placing the barrel onto the conveyor. The machine then uses a pneumatic arm to pick up a lid, place it on the barrel, and finally crimp it securely. Speed is precisely controlled by the drive systems of both the top rollers and the bottom conveyor.

With its rational design, compact structure, 300-500BPH operation, and robust reliability, this machine is the ideal solution for automated capping processes in the lubricant, food, chemical, and daily chemical industries.

Production Application

Automatic plastic pail lid placing & pressing capping machine, automatic pail pressing sealing machine, automatic open barrels pressing machine, automatic paint barrels lid pressing machine, automatic oil barrels pressing machine, automatic drums lid pressing machine, paint bucket lid pressing machine, hand drum pressing seaing capping machine, 1 gallon paint pail pressing capping machine, 9L paint pail pressing closer machinery, 15L motor oil pail pressing sealing machinery, 18Liter engine oil pail sealing packing machinery, 20Liter engine oil plastic pail capping machinery, 25Liter diesel engine oil pail pressing machinery, 5 gallon wide opener bucket capping machine.

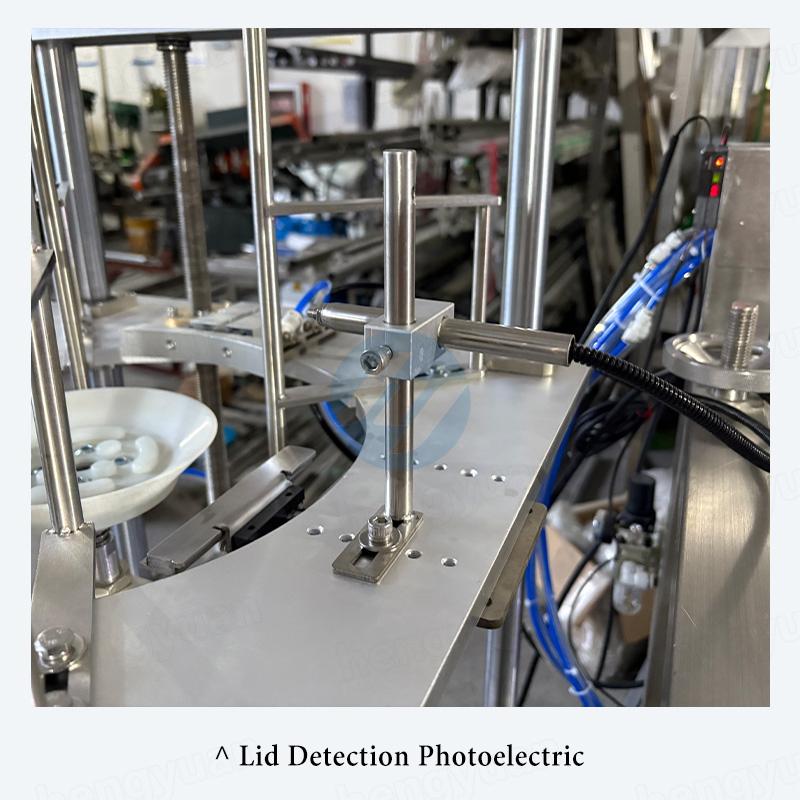

Features an automated pneumatic system for precise picking and placing of lids, ensuring gentle and accurate operation.

2. Powered Roller Pressing

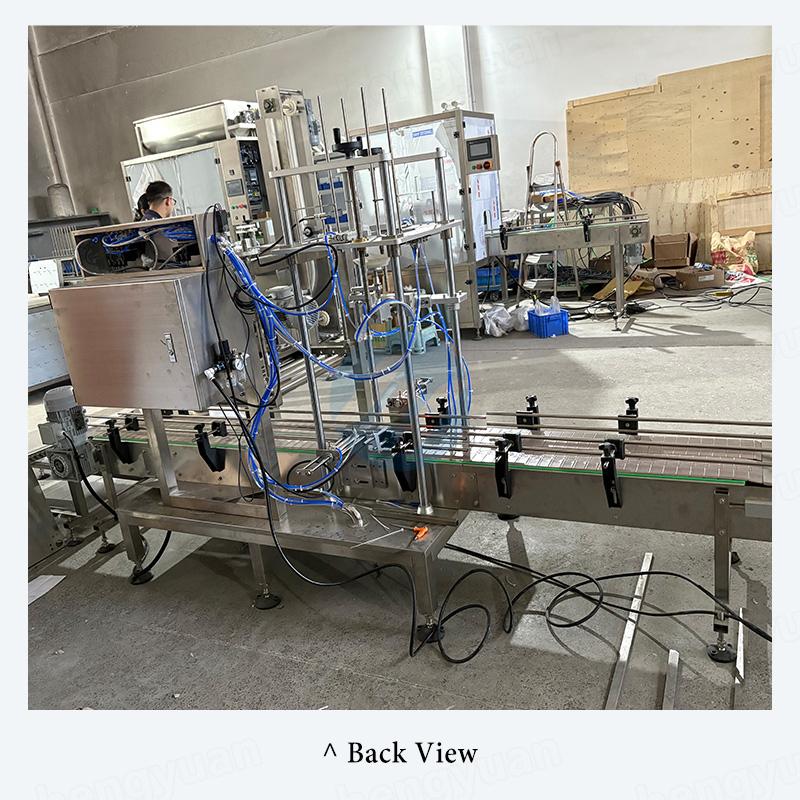

Equipped with a powered roller pressing mechanism that delivers consistent and secure crimping for a reliable seal on wide-mouth barrels.

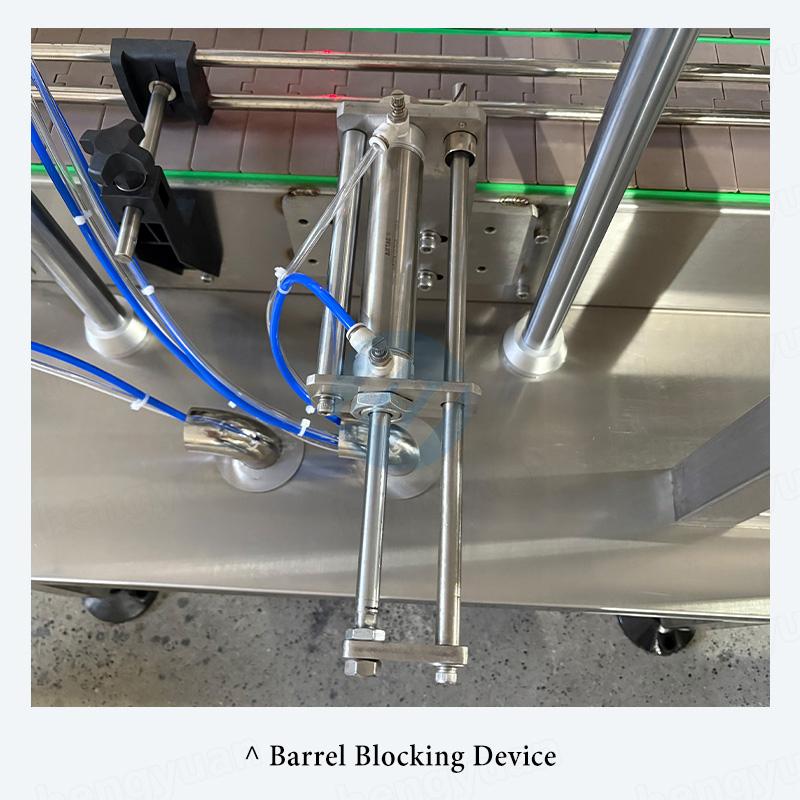

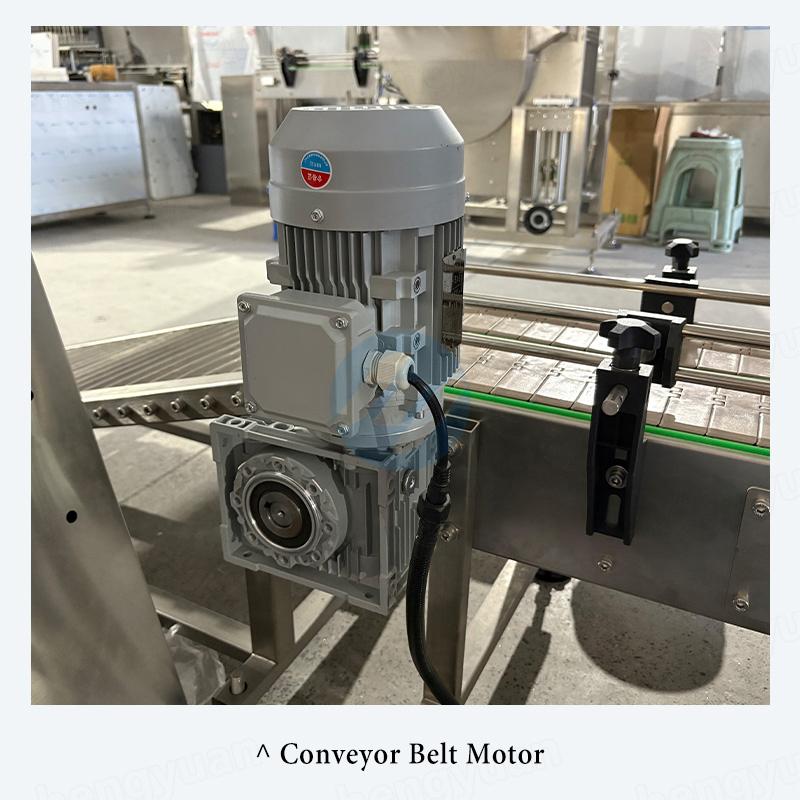

3. Efficient Chain-Plate Conveyor

Incorporates a robust lower chain-plate conveyor for stable barrel transportation, suitable for heavy-duty industrial environments.

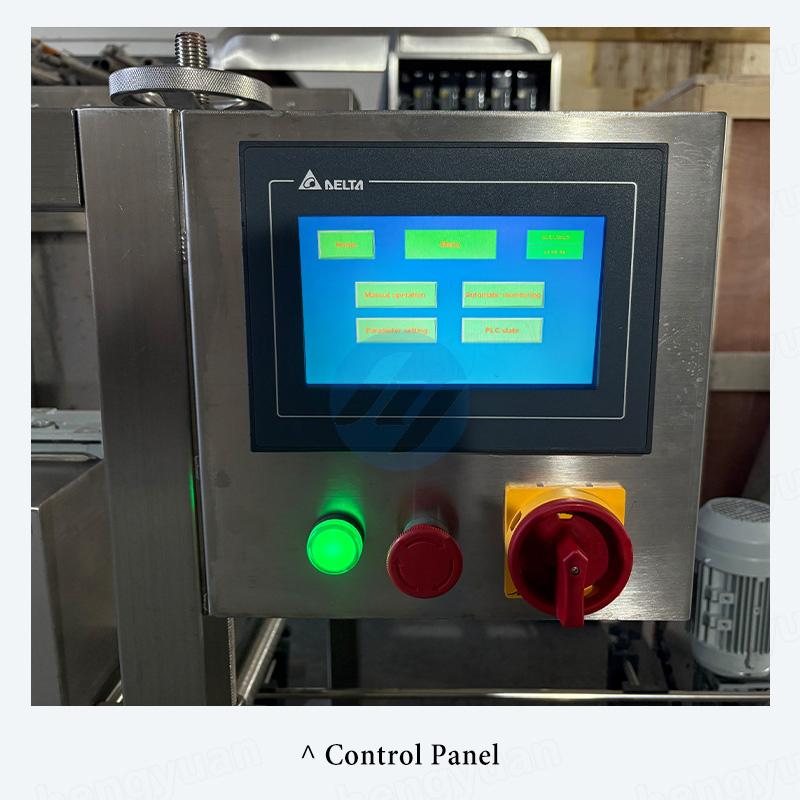

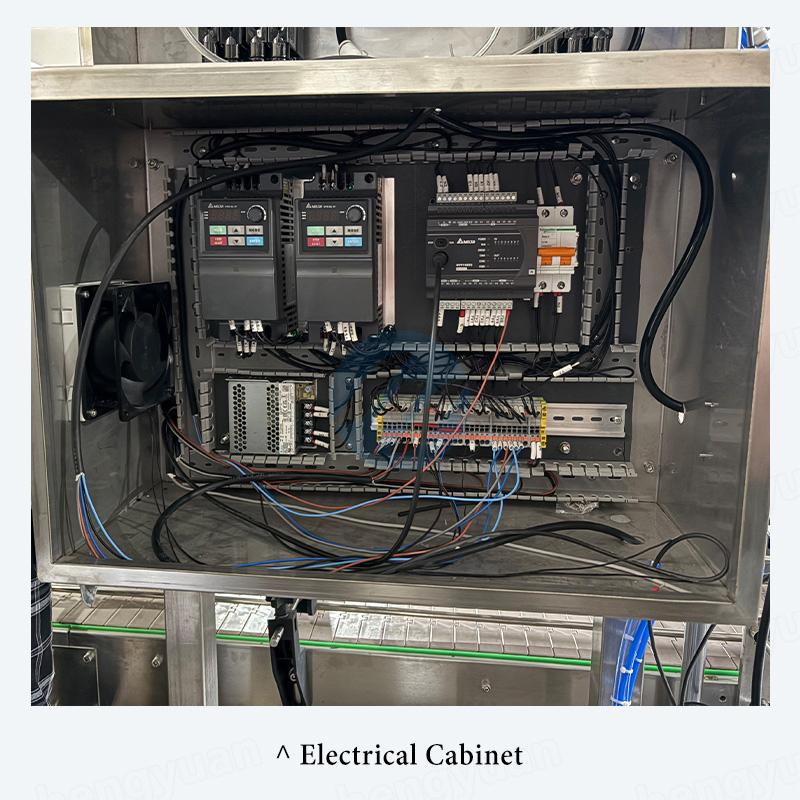

4. User-Friendly PLC Control

Utilizes an advanced PLC control system with an intuitive touchscreen interface for easy operation, monitoring, and parameter adjustment.

5. High-Speed Output

Offers a high production capacity of 300-500 barrels per hour, designed to meet the demands of efficient automated production lines.

6. Synchronized Speed Control

Ensures smooth and precise processing through integrated speed control of both the top rollers and the bottom conveyor.

7. Robust & Compact Design

Boasts a rationally designed, compact structure that guarantees high reliability, fast capping speed, and easy integration into existing workflows.

8. Multi-Industry Application

Product Introduction

Automatic Lid Placing & Capping Machine for Wide-Mouth Barrels is designed for placing and crimping lids onto wide-mouth barrels. It features a pneumatic system for picking and placing lids, a powered roller pressing mechanism, and a lower chain-plate conveyor. The operation is simple, maintenance is straightforward, and performance is highly reliable.

It is ideally suited for capping large smooth-rim barrels, such as those for lubricating oil and coatings. The process begins by placing the barrel onto the conveyor. The machine then uses a pneumatic arm to pick up a lid, place it on the barrel, and finally crimp it securely. Speed is precisely controlled by the drive systems of both the top rollers and the bottom conveyor.

With its rational design, compact structure, 300-500BPH operation, and robust reliability, this machine is the ideal solution for automated capping processes in the lubricant, food, chemical, and daily chemical industries.

Production Application

Automatic plastic pail lid placing & pressing capping machine, automatic pail pressing sealing machine, automatic open barrels pressing machine, automatic paint barrels lid pressing machine, automatic oil barrels pressing machine, automatic drums lid pressing machine, paint bucket lid pressing machine, hand drum pressing seaing capping machine, 1 gallon paint pail pressing capping machine, 9L paint pail pressing closer machinery, 15L motor oil pail pressing sealing machinery, 18Liter engine oil pail sealing packing machinery, 20Liter engine oil plastic pail capping machinery, 25Liter diesel engine oil pail pressing machinery, 5 gallon wide opener bucket capping machine.

Main Features

1. Pneumatic Lid HandlingFeatures an automated pneumatic system for precise picking and placing of lids, ensuring gentle and accurate operation.

2. Powered Roller Pressing

Equipped with a powered roller pressing mechanism that delivers consistent and secure crimping for a reliable seal on wide-mouth barrels.

3. Efficient Chain-Plate Conveyor

Incorporates a robust lower chain-plate conveyor for stable barrel transportation, suitable for heavy-duty industrial environments.

4. User-Friendly PLC Control

Utilizes an advanced PLC control system with an intuitive touchscreen interface for easy operation, monitoring, and parameter adjustment.

5. High-Speed Output

Offers a high production capacity of 300-500 barrels per hour, designed to meet the demands of efficient automated production lines.

6. Synchronized Speed Control

Ensures smooth and precise processing through integrated speed control of both the top rollers and the bottom conveyor.

7. Robust & Compact Design

Boasts a rationally designed, compact structure that guarantees high reliability, fast capping speed, and easy integration into existing workflows.

8. Multi-Industry Application

The ideal automated capping solution for a wide range of industries, including lubricants, coatings, food, chemicals, and daily chemicals.