Description

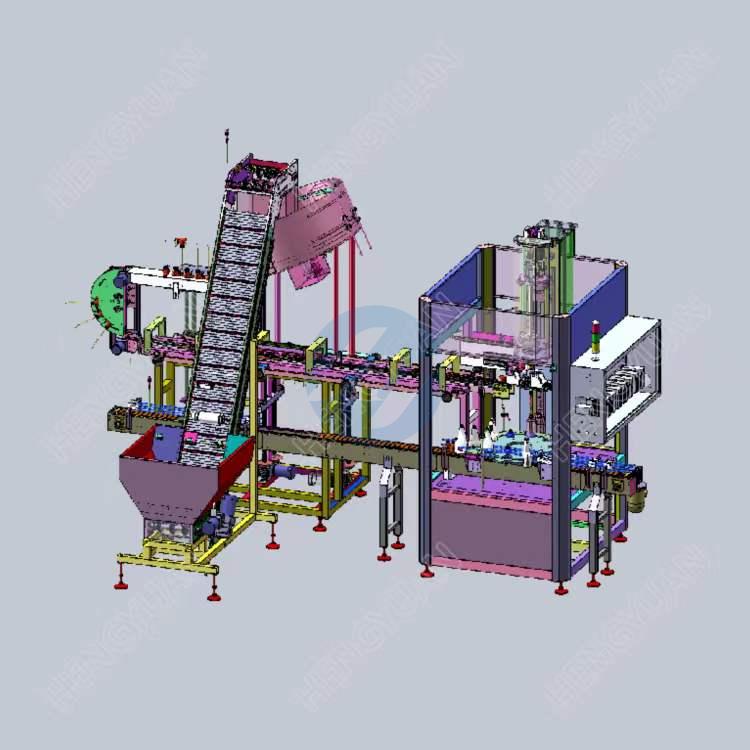

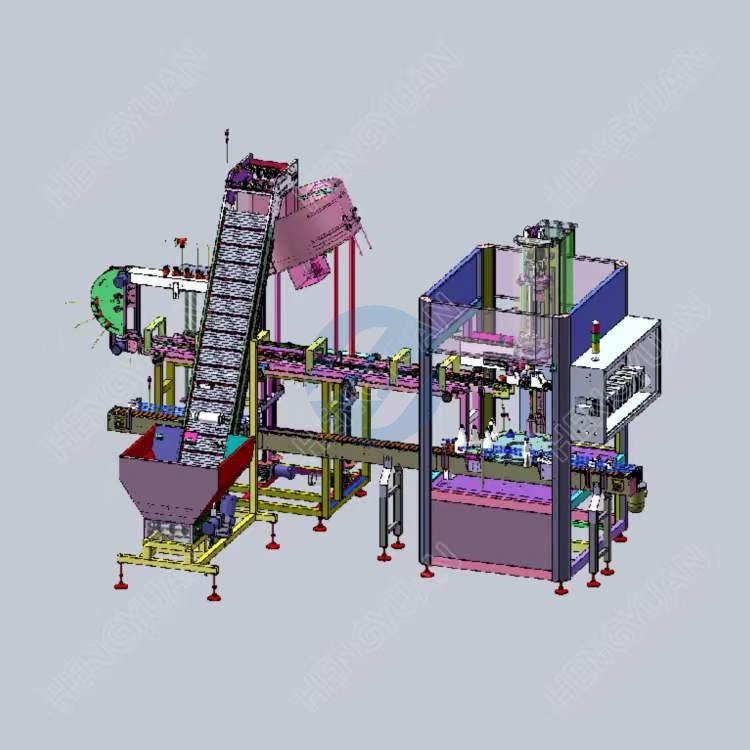

HYFK-100 Automatic Single Head

Trigger and Pump Lid Bottle Capping Machine

Product Introduction

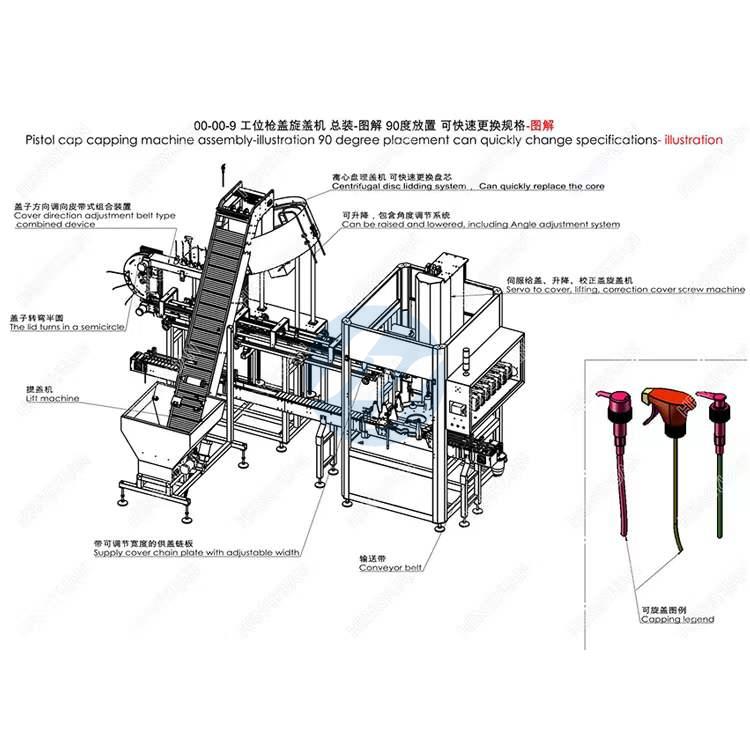

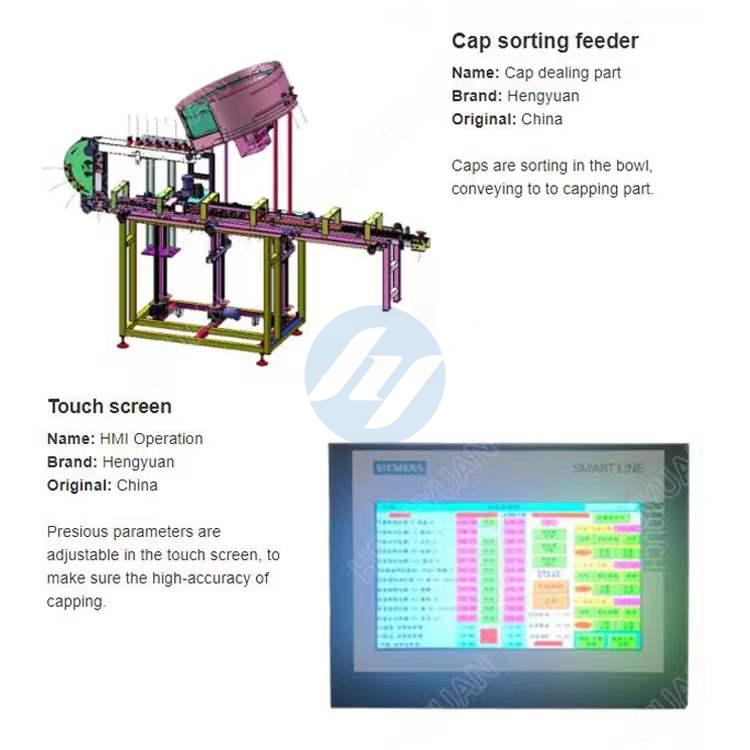

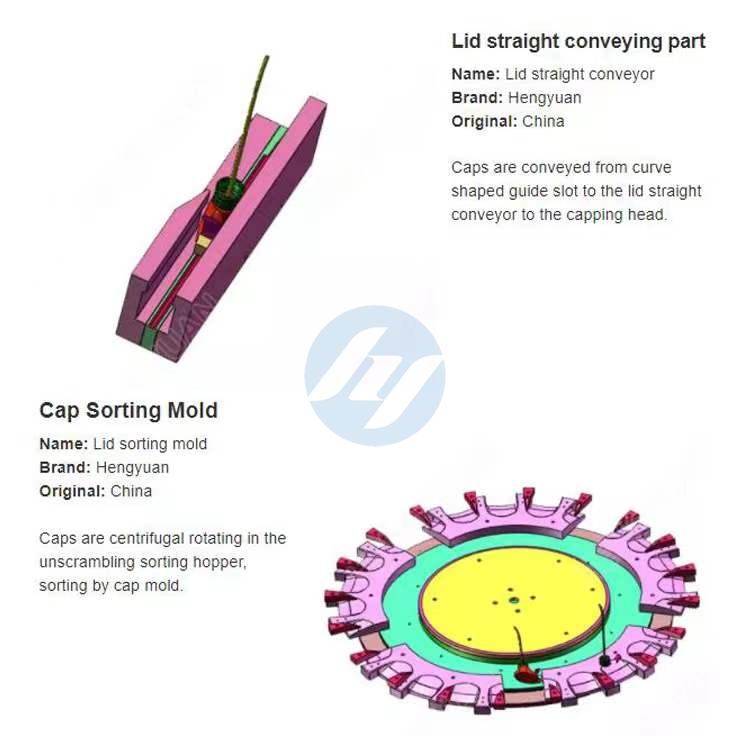

The pump or trigger capper is a machine for automatic feeding and capping of trigger lids, cosmetic pumps (and traditional caps). Application of a servo-drive allows full control of the capping process and facilitates fast machine changeover (fast format change for various package types).1.Cap elevating machine lifts the caps to the storage box of the Centrifugal disk.

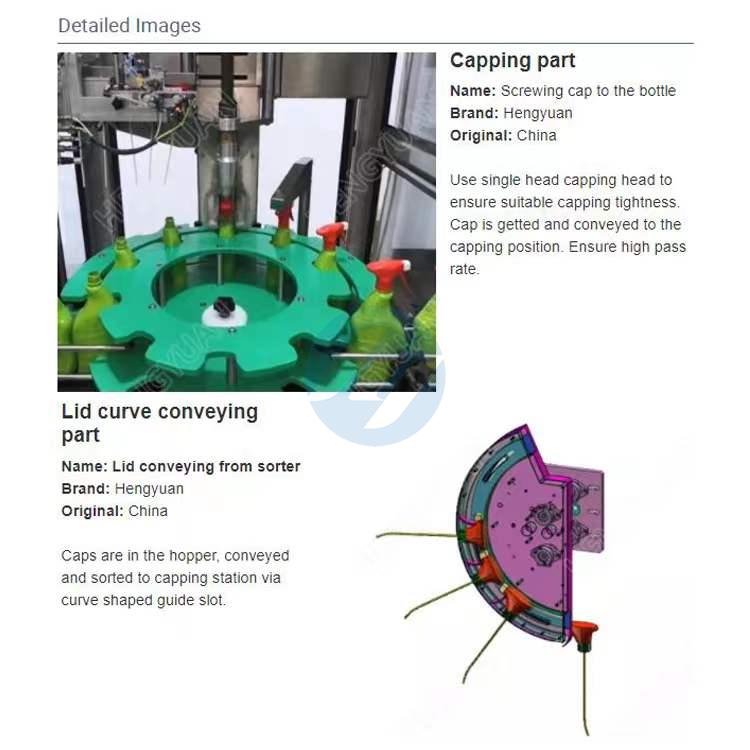

2.The centrifugal disc sorts out the caps with different lengths of straw and sends them to the cap feeding track to the belt type positive cap device.

3.The single head full servo capping machine sends the caps to the cap clamping cylinder through the cap feeding conveyor belt. Driven by the linear servo feeding cap, the two claws first loosen and then close and grasp the cap when the cap is at the highest position. The capping head descends under the driving of the lifting servo motor. The cap calibration cylinder first retracts the collet, and then covers the core clamp of the straw. The cylinder for clamping the suction pipe is located in the servo motor Drive, stop at the mouth of the bottle. When the pipette is reliably inserted into the bottle mouth, the cylinder of clamping tube opens and continues to descend, and the capping head continues to drop, screw the cap on the bottle. The outlet nozzle of the pump cap is blocked by an adjustable eccentric centering rod on the capping head, so that the outlet nozzle of the pump cap is always connected with the bottle Keep your body at a fixed angle. Screw cap tightness can be adjusted by servo motor on the touch screen.

4.This machine adopts servo control mode, which can quickly adjust in place when product specifications are changed. The height of the bottle body and the length of the suction tube can be set. When changing the specifications, the parameters of the corresponding bottle shape specifications can be directly called, and the cylinder for calibrating the suction pipe is calibrated in place under the driving of the lifting servo motor. At the same time, the positioning pin is installed on the main turntable, which can be quickly replaced. Each set of star wheel turntable has a digital code, which can not be confused.

Screwing cap torque is directed controlled on touch; no need to adjust the height of the cover.

If the size of the lid head is the same, the length of the tube is different, changing a specification, only need 5 minutes.

Product Application

HYFK-100 Automatic Single Head Trigger and Pump Lid Bottle Capping Machine

For example:Bug cleaner bottle, Kitchen cleaner bottle, Degerming agent, Shampoo bottle, Hand sanitizer, Body wash bottles, etc. Automatic Single-head Capping Machine.