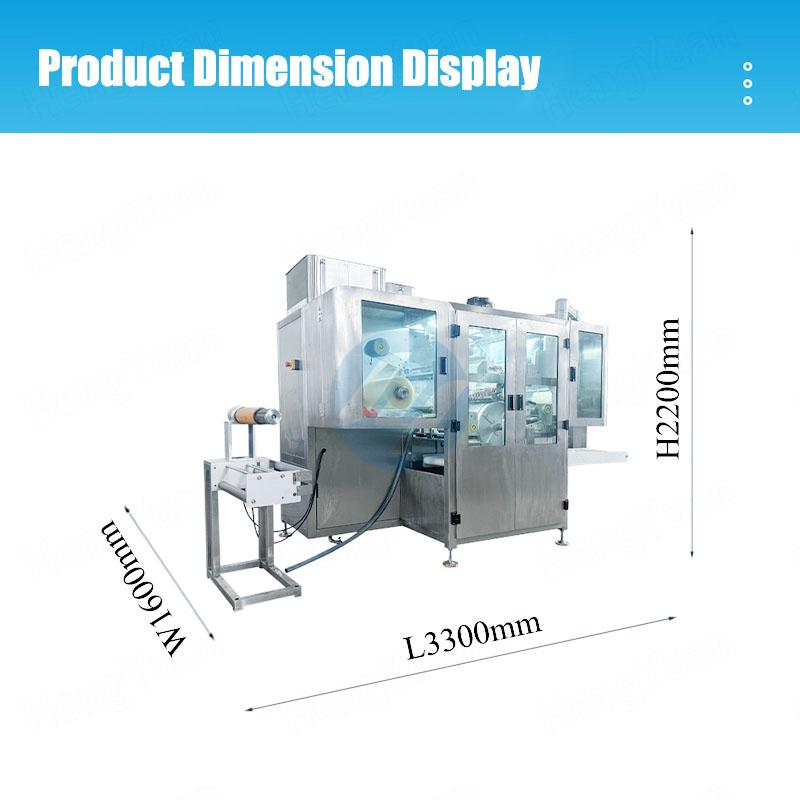

Description

HYSR-300RG Automatic Rolling Type PVA Pods Packaging Machine

Product Description

Product Introduction

The HYSR-300RG series laundry PVA bead packing machine is a special automatic molding and filling equipment for drum-type single-cavity or multi-cavity small-dose liquid. It is a high-speed automatic packaging machine specially developed for the independent quantitative packaging of power, granules, laundry detergent, non-aqueous oil agent and chemicals, and has good adaptability to film and liquid agent. HYSR-300RG series dies can be replaced, and the die system is easier to clean and maintain. It is easier to maintain and maintain for seasonal startup. Especially suitable for small-dose quantitative packaging of pesticide emulsifiable concentrate preparation, high-concentration laundry detergent, chemical oily preparation and other non-aqueous systems. It is the preferred packaging method for enterprise product upgrade.

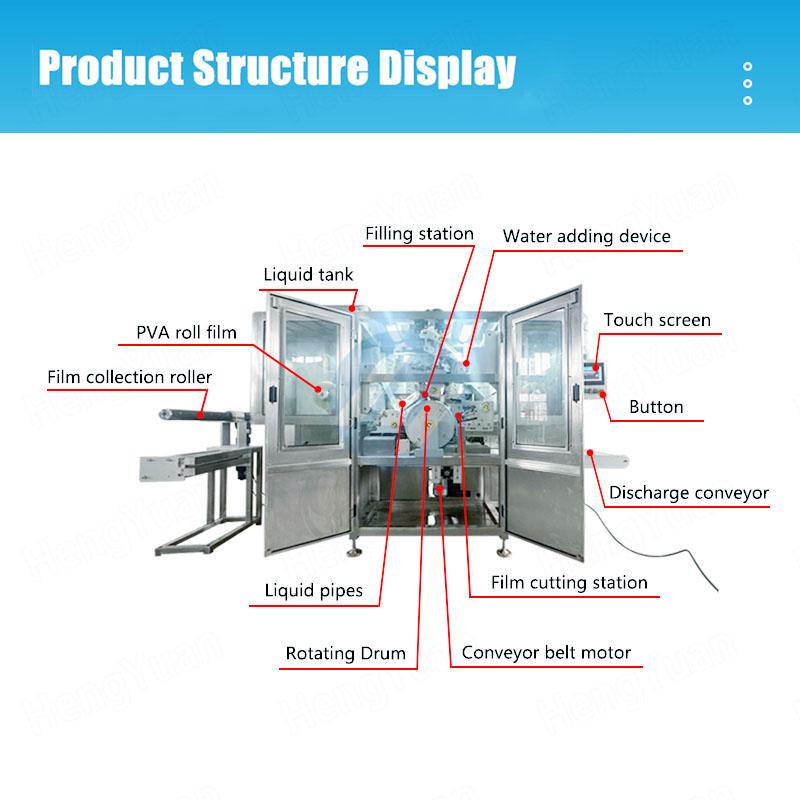

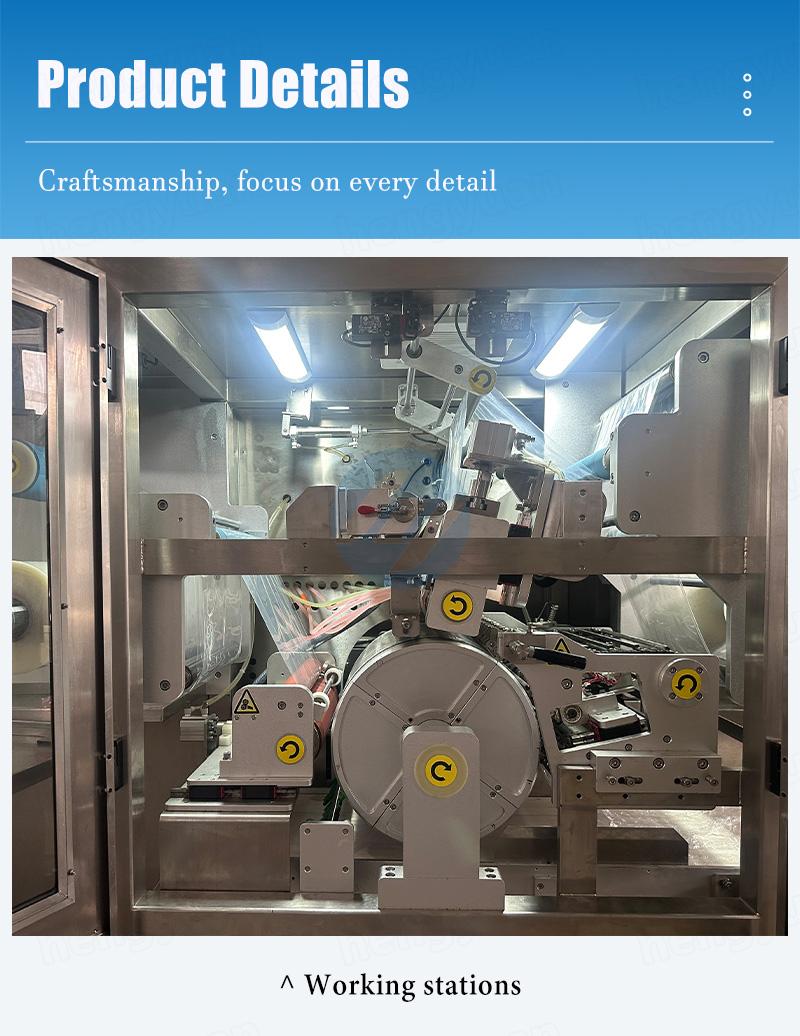

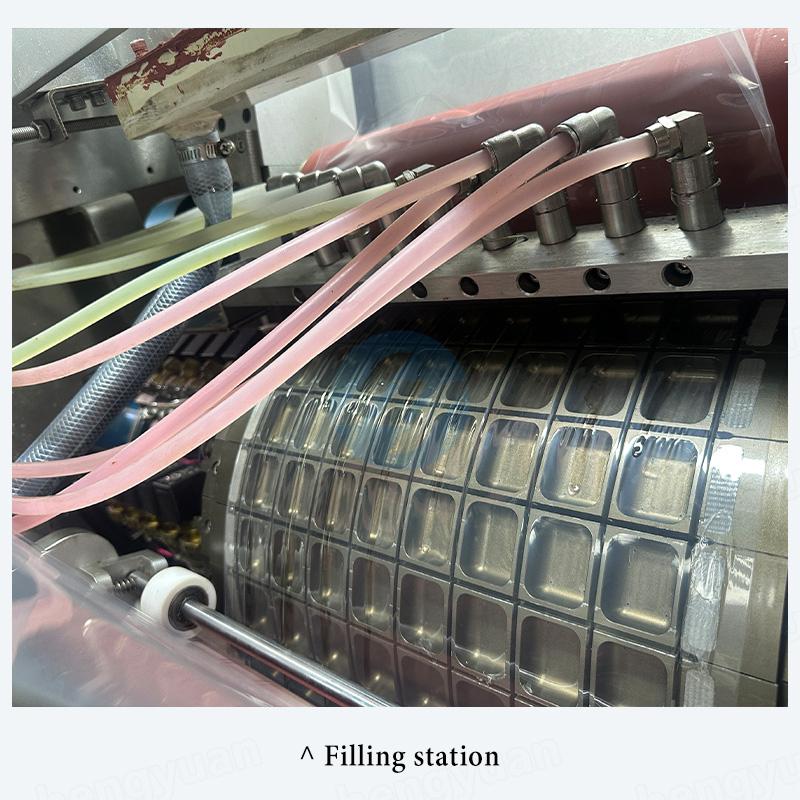

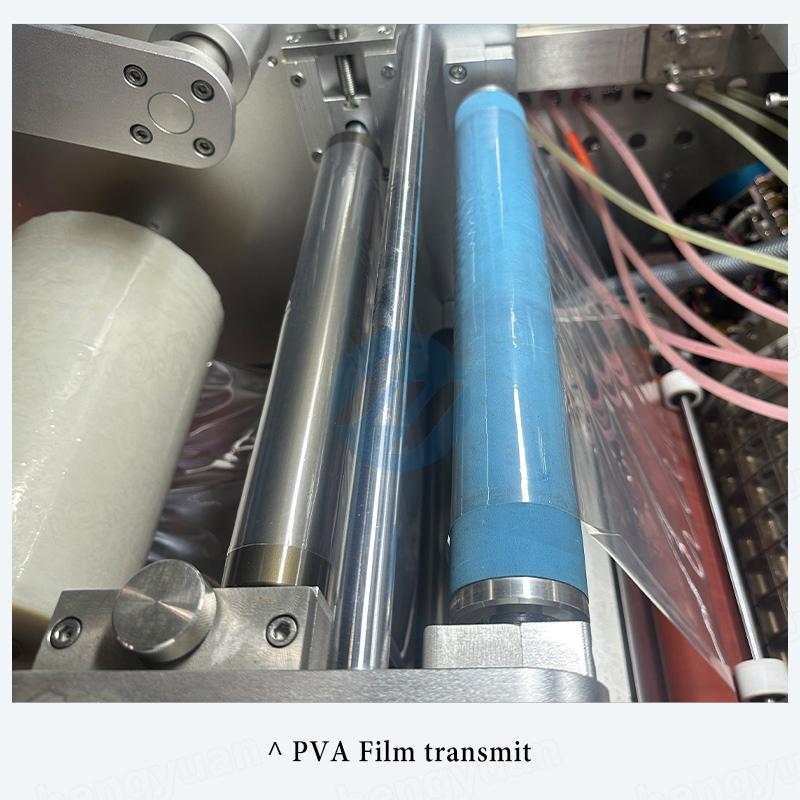

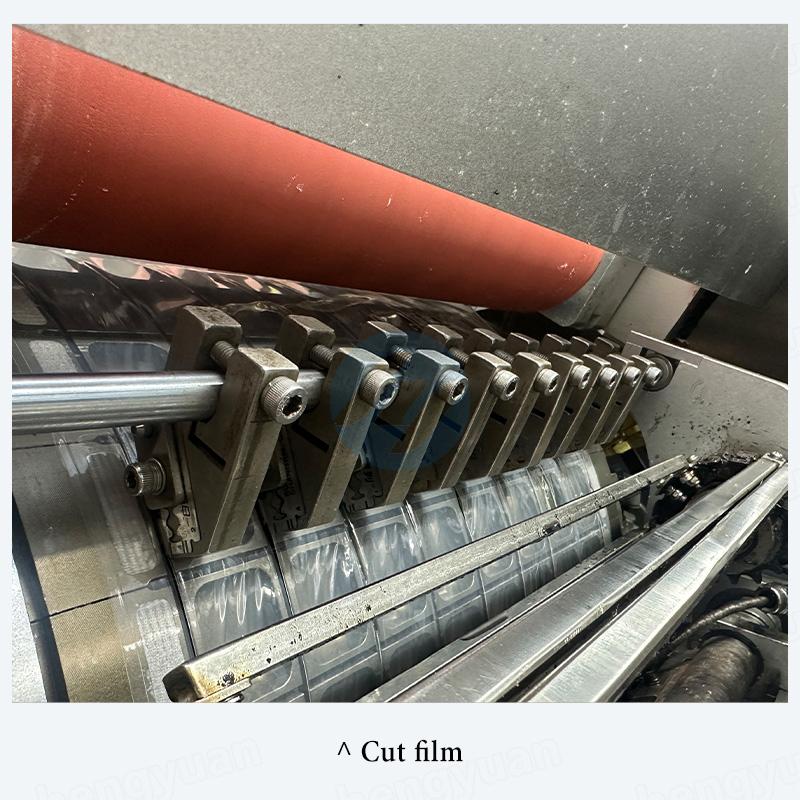

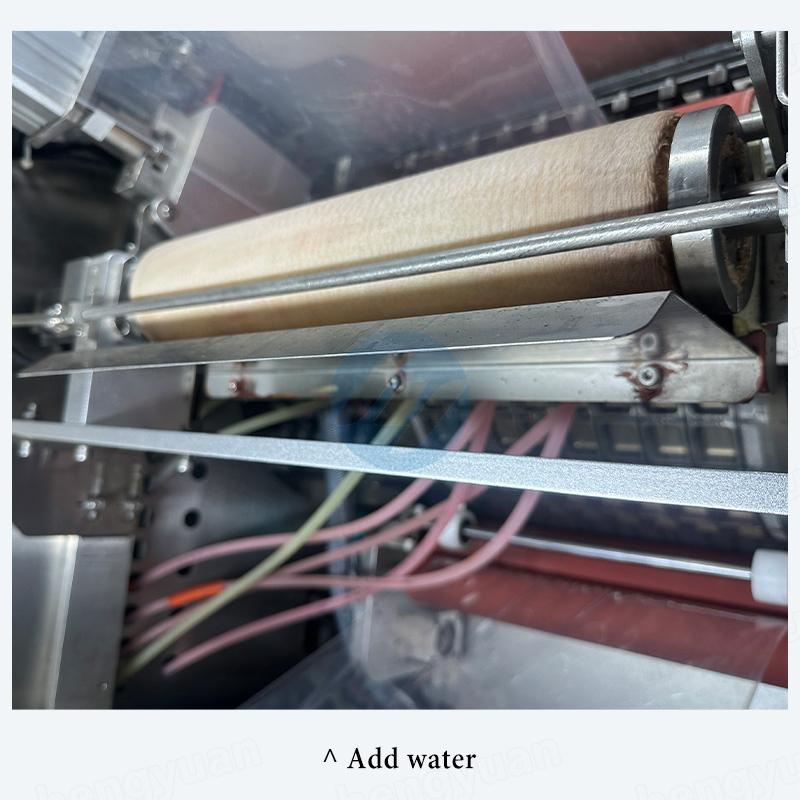

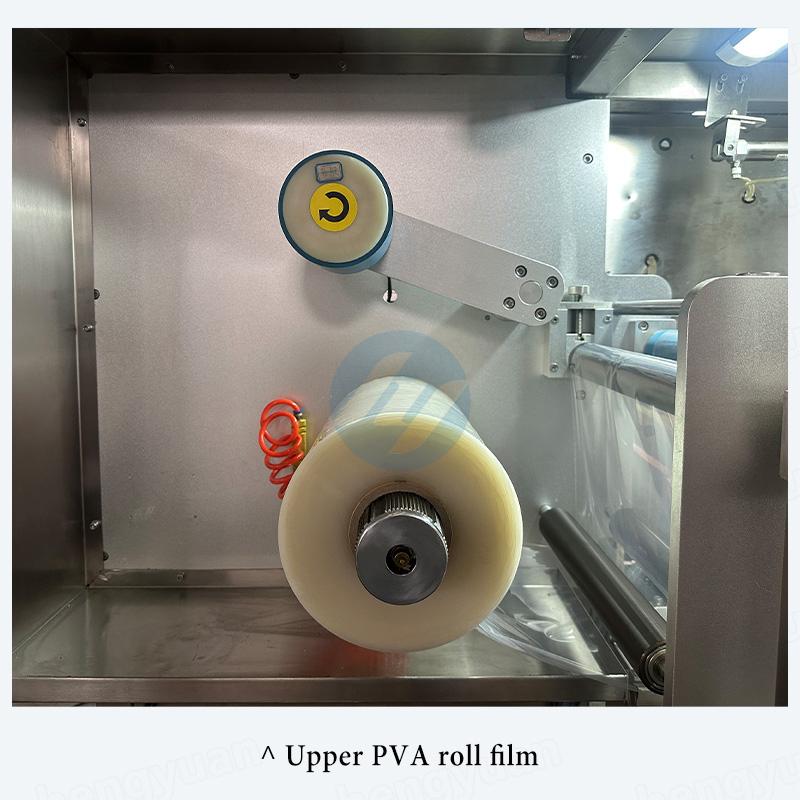

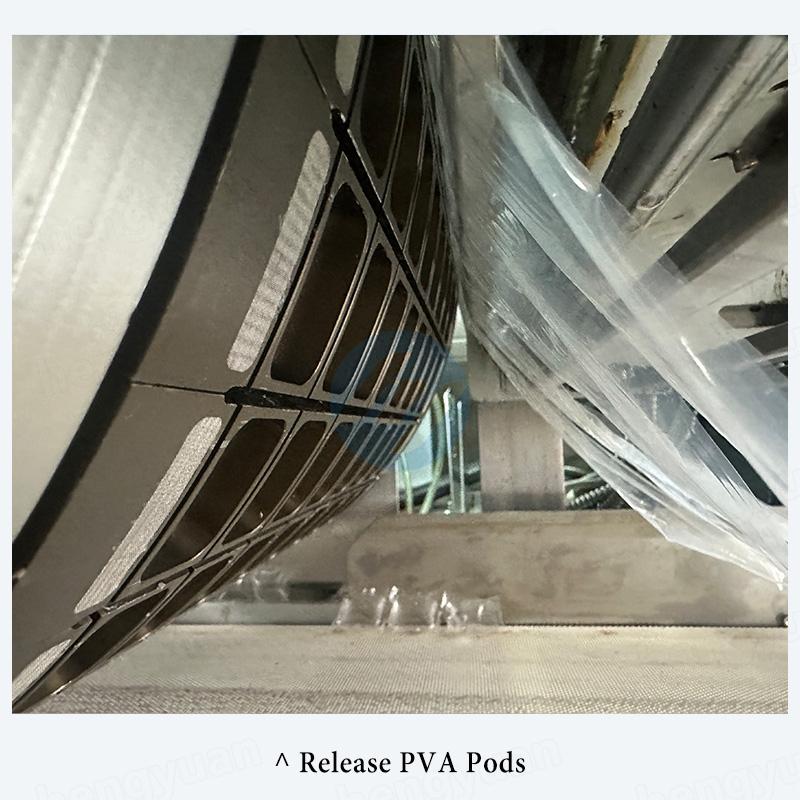

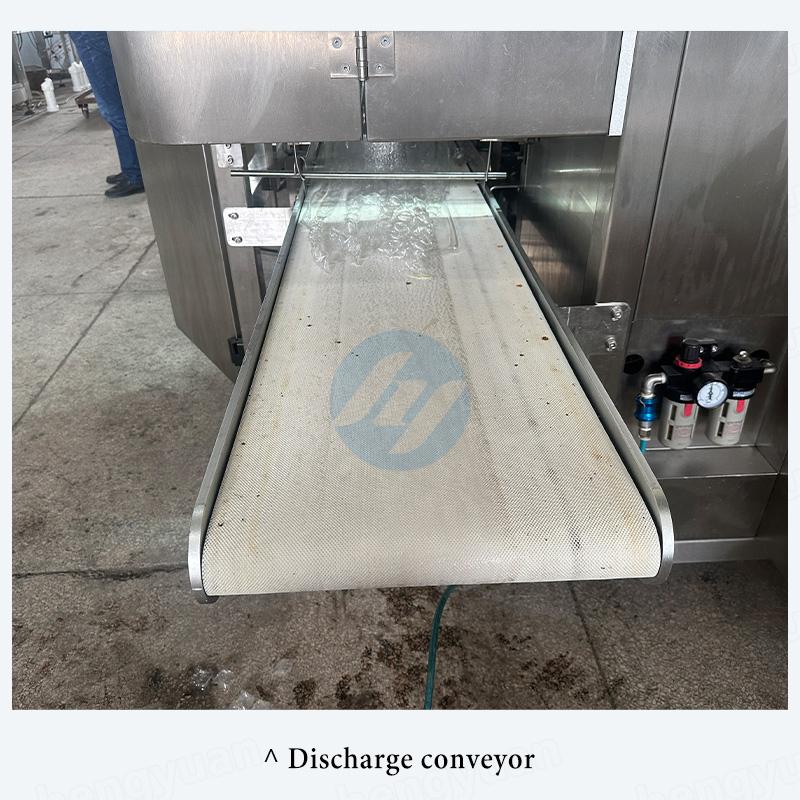

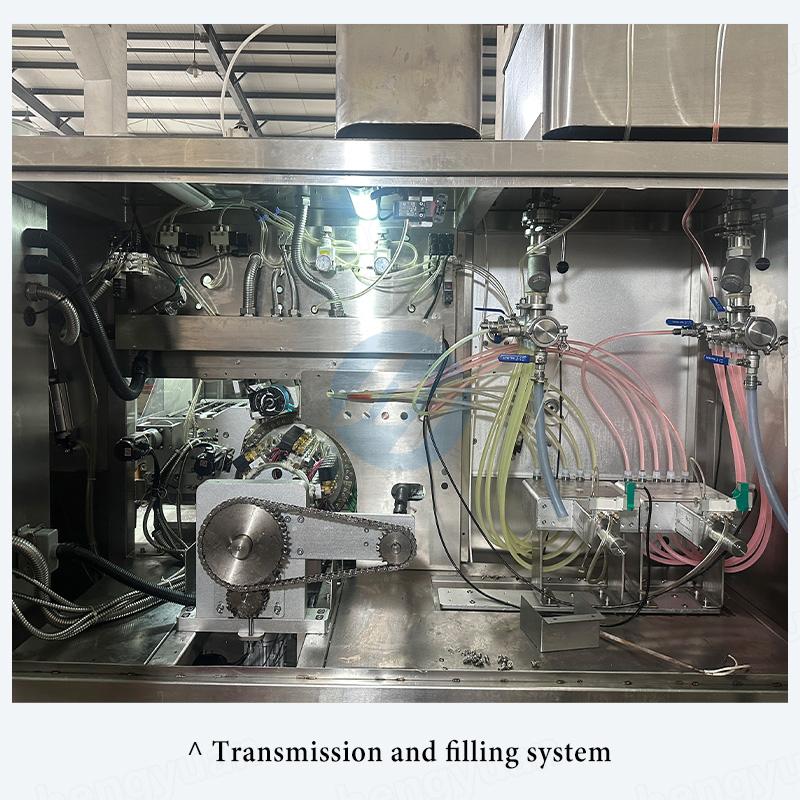

The PVOH bead packing machine comprises a frame, a bottom film unwinding mechanism, a bottom film preheating mechanism, an upper film unwinding mechanism, a filling forming mechanism, a particle packaging mechanism, a water sealing mechanism, a cutter mechanism and a conveyor belt. The filling and molding mechanism comprises a vacuum-pumping roller and a filling mechanism, wherein the vacuum-pumping roller is provided with a vacuum roller shaft, and the filling mechanism injects liquid materials or particles into a concave cavity on the surface of the vacuum-pumping roller (i.e., a mold), and the surface of the roller can be made into a concave cavity with arbitrary shapes, and vacuum suction holes are arranged in the concave cavity to realize the packaging of laundry balls with different specifications; Liquid filling is servo gear pump filling, and high-precision filling of laundry balls of various specifications can be realized by controlling the rotation angle of gear pump. The filling amount can be adjusted on the operation interface, and the mold can be quickly replaced; Particles are filled in measuring cup type free fall, and the quantitative filling of particles in a certain cavity is completed by switching back and forth with pneumatic swing block, and the mold can be replaced as a whole.

Product Application

PVA water soluble film as packing material. Finished products listed like detergent beads, laundry detergent pod, floor cleaning liquid pods, toilet bowl cleaner powder beads, dish washing powder pva capsules, laundry liquid and granules beads, and other chemical pods.

HYSR-300RG Automatic Rolling Type Dishwash Powder PVA Pods Packing Machine

Main Features

1. The mold adopts integrated roller design. After training, customers can quickly replace the mold. When changing different packaging shapes, they only need to replace the mold and adjust the corresponding pipeline. The corresponding program and gram weight (monochrome, double color, three color or multi color) are selected on the touch screen. The pipeline connected with the material is a clamp-type quick joint, which is simple and convenient to operate. After training, the replacement can be completed. Other manufacturers need to send professionals to replace the mold, or even return to the factory for renovation.

2. The liquid filling system is a full servo filling system, which has a wide adjustment range of gram weight. The filling quantity is controlled by controlling the turning angle of servo. The filling precision is very high. The filling head is designed to meet the packaging requirements of single cavity, double cavity and three cavities. There is no seal, and the maintenance is simple. Each cavity corresponds to a set of filling system, so the adjustment of gram weight is convenient and flexible. Other manufacturers adopt piston filling system, which requires regular replacement of seals and tedious maintenance. With the wear of seals and the influence of air pressure, the filling accuracy decreases, so it is necessary to regularly check the gram weight of products and then make manual mechanical compensation. Each filling system is uneven and there are too many uncertain factors, and the filling piston is combined, which is not independent and is not conducive to product upgrading; Only a few manufacturers have mastered this packaging technology for particulate filling; Powder and granules dosing use cup volume measurement.

3. After packaging and molding, the slitting device is a servo slitting system, which ensures reliable and stable slitting. There is no pneumatic component, and there is no trouble of changing seals regularly. The equipment can run continuously for a long time. Some manufacturers use pneumatic devices, which are affected by air pressure and pipeline, and are prone to impact the cutter and even damage the mold. It is necessary to check the pipeline connection regularly. The equipment is unreliable and cumbersome to maintain.

4. The liquid replacement operation is simple, which can be completed within a few minutes and can be completed in the operation interface without disassembling the pipeline;

5. The unwinding of the bottom film and the top film is controlled by a tension sensor, the tension is constant, and the size and plumpness of the produced beads are stable;

6. The sealing form is water seal, and the amount of water covered by the membrane is controlled by servo digital quantity. The parameters can be adjusted in the operation interface without mechanical adjustment, and the precision is extremely high. For membranes from different manufacturers, the membrane can be produced immediately by inputting the corresponding tested parameters

Machine Display

click here to view HYSR-300RG Automatic Rolling Type PVA Pods Packaging Machine running video on YouTube