Description

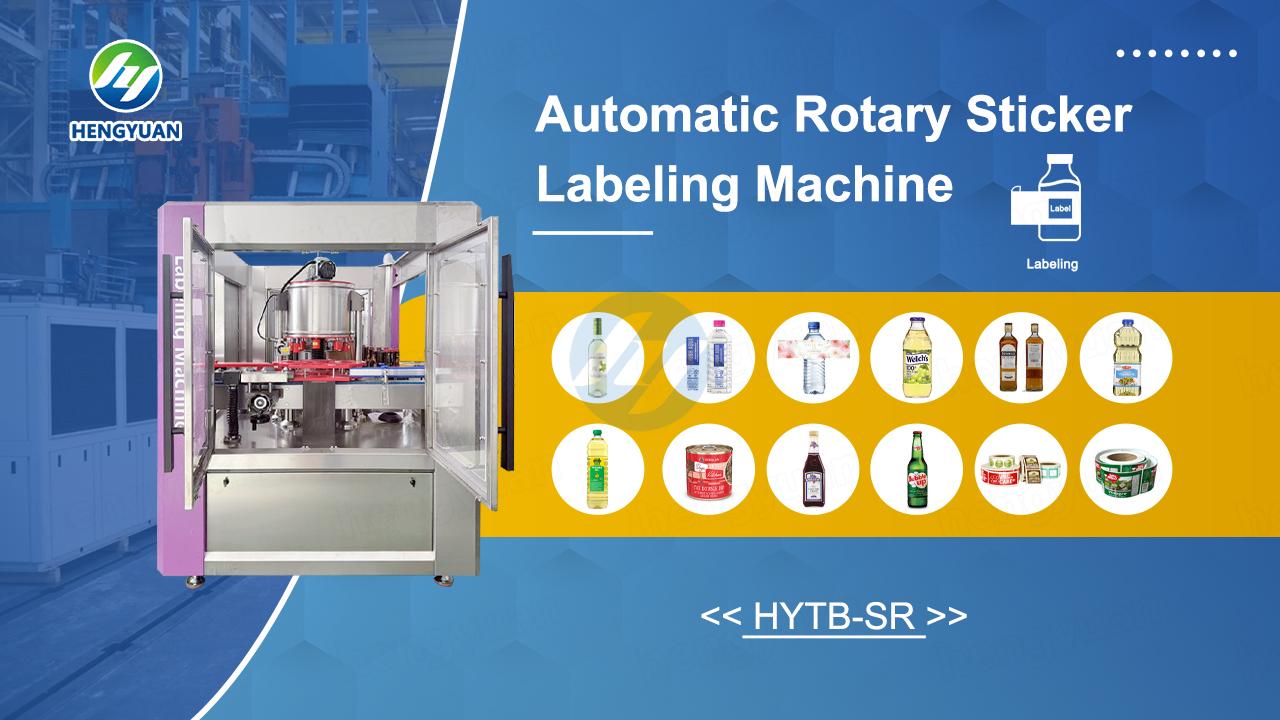

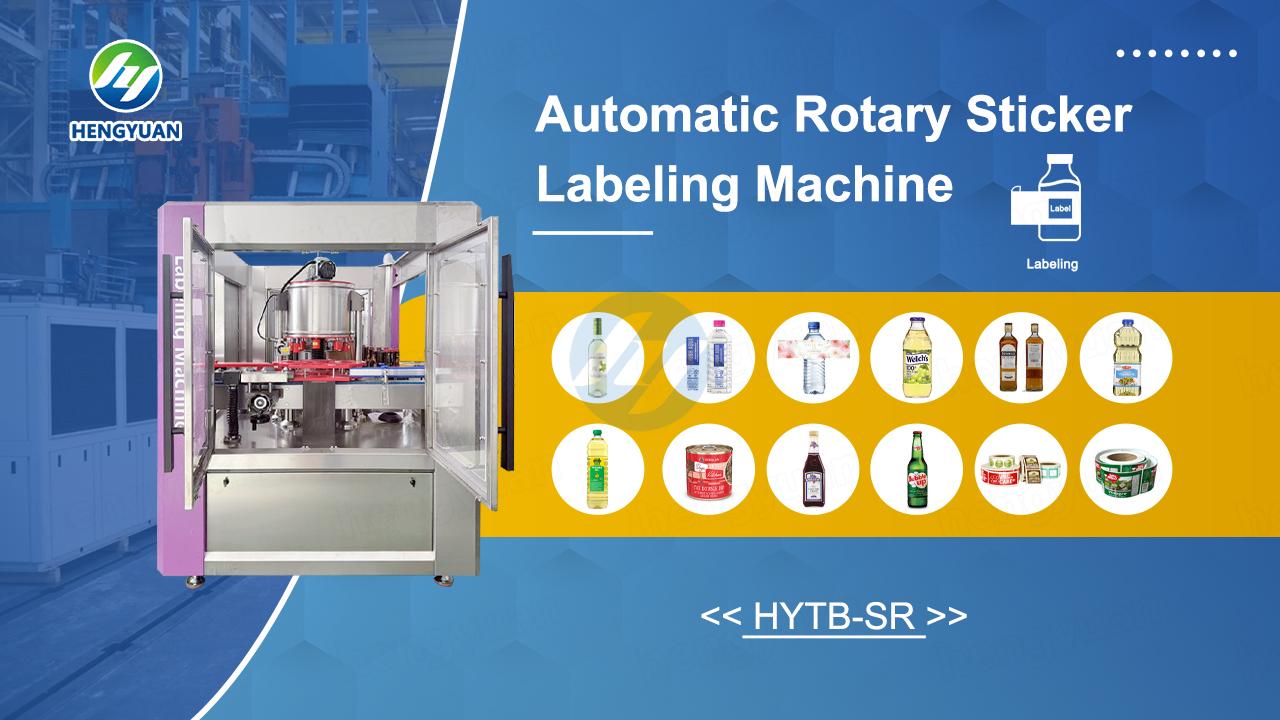

HYTB-SR Automatic Rotary Sticker Labeling Machine

Product Introduction

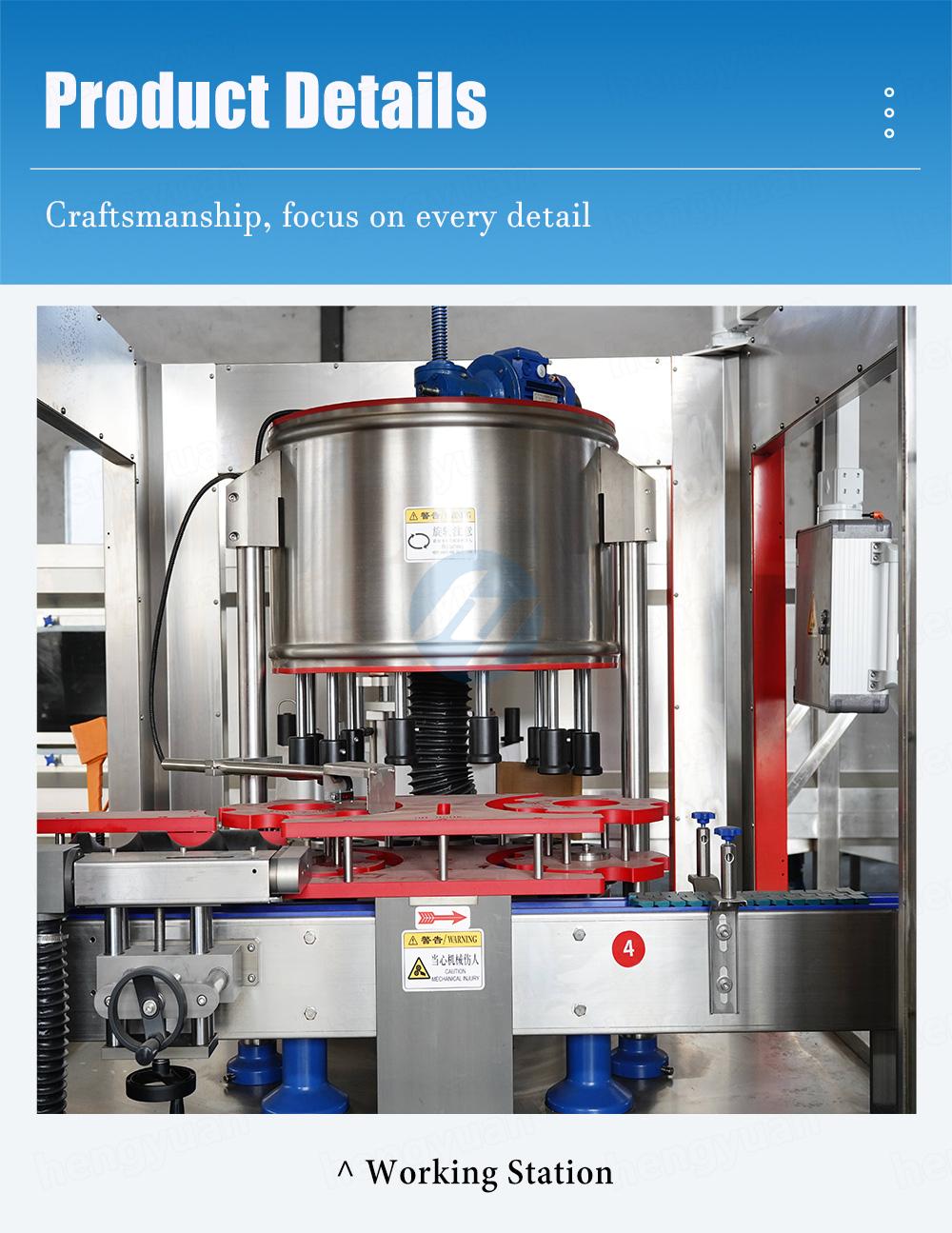

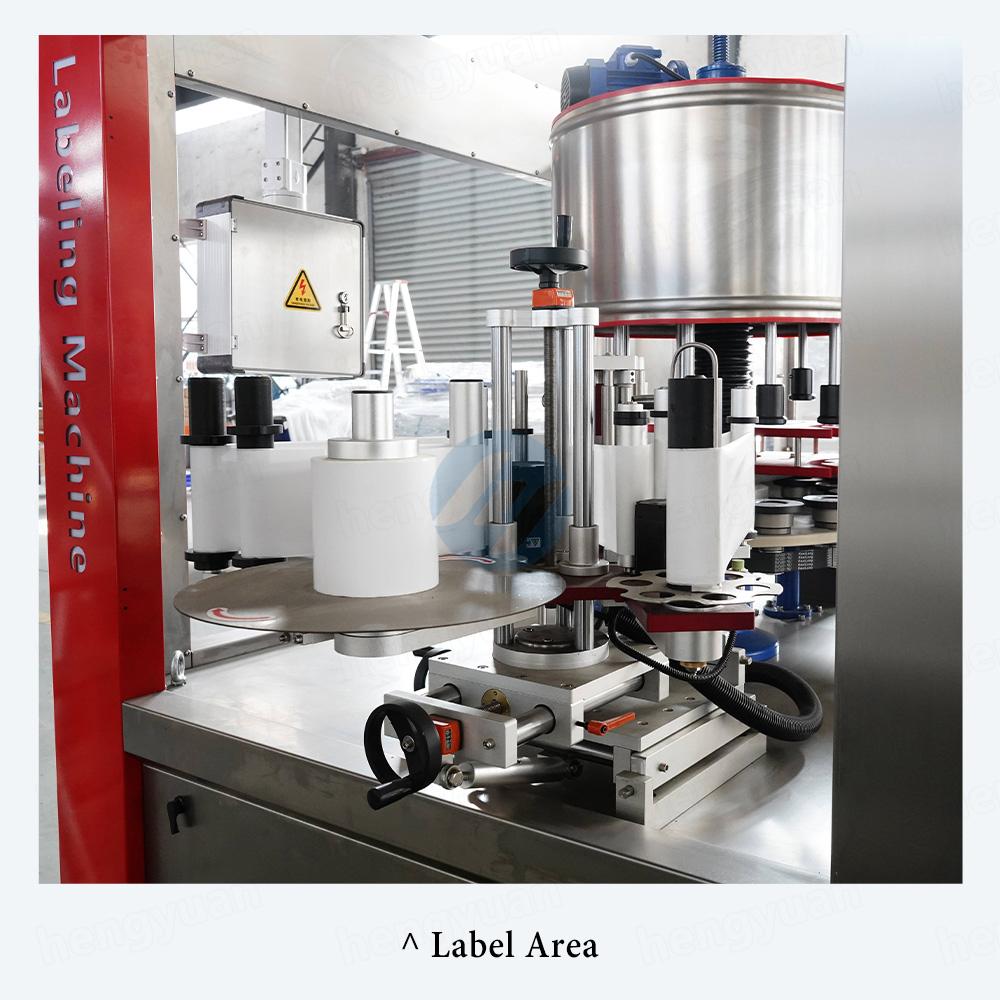

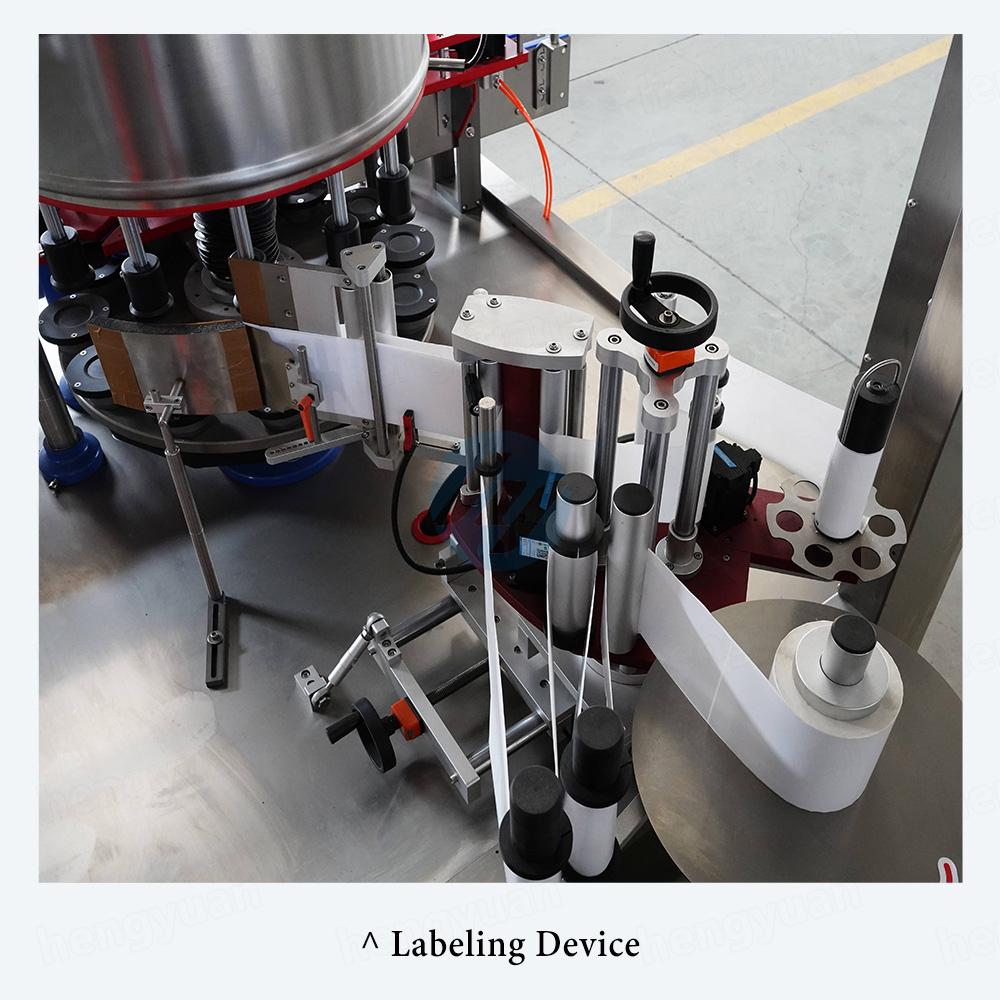

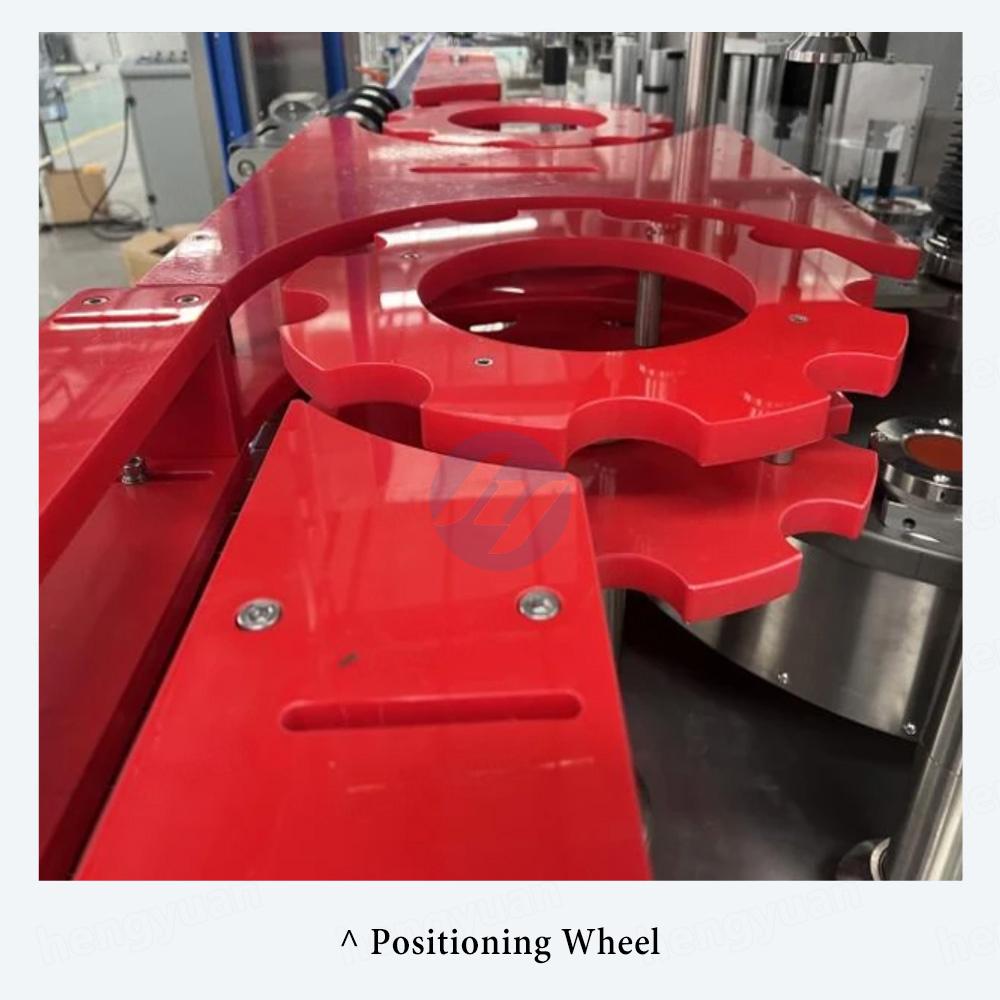

Our company produces a rotary adhesive labeling machine designed as a continuous high-speed labeling system. The equipment employs an advanced PLC-based microcomputer control system combined with a touchscreen interface, enabling intelligent and user-friendly operation. It features automatic adjustment of conveying and output functions: products transported via the conveyor belt are evenly spaced by the dividing screw according to the star wheel's intervals, then transferred by high-performance POM (polyoxymethylene) star wheels to the rotary disc. After being secured by the bottle pressing mechanism and product mold base, the product rotates at a set speed, with mechanical pre-positioning ensuring accurate label application along the designed motion trajectory. The machine can be customized to accommodate containers of various specifications, including bottles, cans, and drums. Suitable for adhesive sticker label on plastic, metal, glass and other round, square containers. Labeling stations: 6,12, 18, 24, 30, 36can be specially designed according to customer requirements. Widely used in beverage, drinking, food, chemical and other industries.

Product Application

Product Introduction

Our company produces a rotary adhesive labeling machine designed as a continuous high-speed labeling system. The equipment employs an advanced PLC-based microcomputer control system combined with a touchscreen interface, enabling intelligent and user-friendly operation. It features automatic adjustment of conveying and output functions: products transported via the conveyor belt are evenly spaced by the dividing screw according to the star wheel's intervals, then transferred by high-performance POM (polyoxymethylene) star wheels to the rotary disc. After being secured by the bottle pressing mechanism and product mold base, the product rotates at a set speed, with mechanical pre-positioning ensuring accurate label application along the designed motion trajectory. The machine can be customized to accommodate containers of various specifications, including bottles, cans, and drums. Suitable for adhesive sticker label on plastic, metal, glass and other round, square containers. Labeling stations: 6,12, 18, 24, 30, 36can be specially designed according to customer requirements. Widely used in beverage, drinking, food, chemical and other industries.

Product Application

Automatic sticker labeling machine, high-speed label applicator, wine bottle sticker labeling machine, tin can adhesive sticker labeling machine, aluminum can label applicator, glass bottle sticker labeling machine, beverage pet bottle label applicator, plastic bottle sticker label applicator, etc.

Main Features

Technical Parameters

Labeling heads

6, 12, 18, 24, 30, 36pcs

Labeling capacity

6000-36000pcs/hour

Labeling glue

Self-adhesive Sticker Label

Labeling accuracy

±1mm

The inner diameter of label roll

76 mm

The outer diameter of label roll

350 mm(max)

The maximum label width

200 mm

The minimum label width

15mm

The suitable size of objects

≤90mm

Operating direction

Left or Right

Air pressure

0.6Mpa

Total Power

6kw

Power supply

AC220V/380V/415V/440V, Three phases. Globally customized

Net weight

About 2200kg

Machine size

210x200x200cm

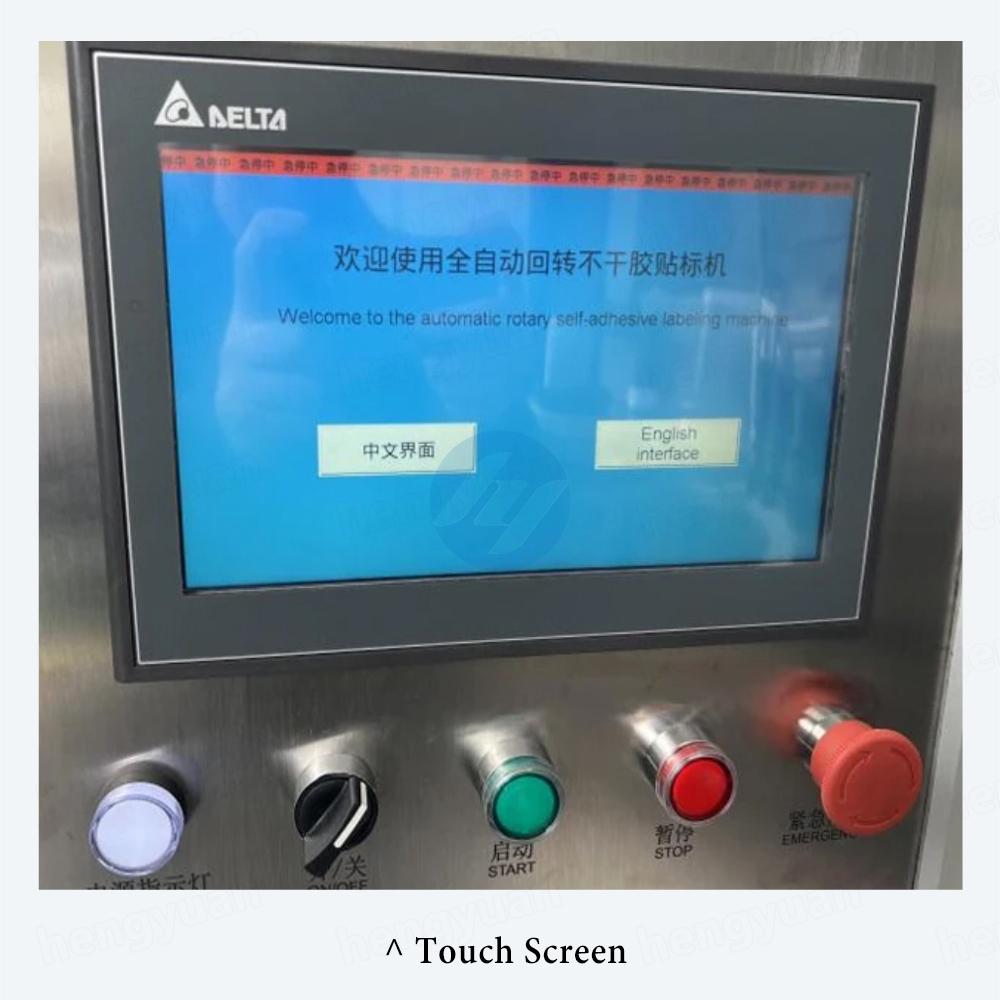

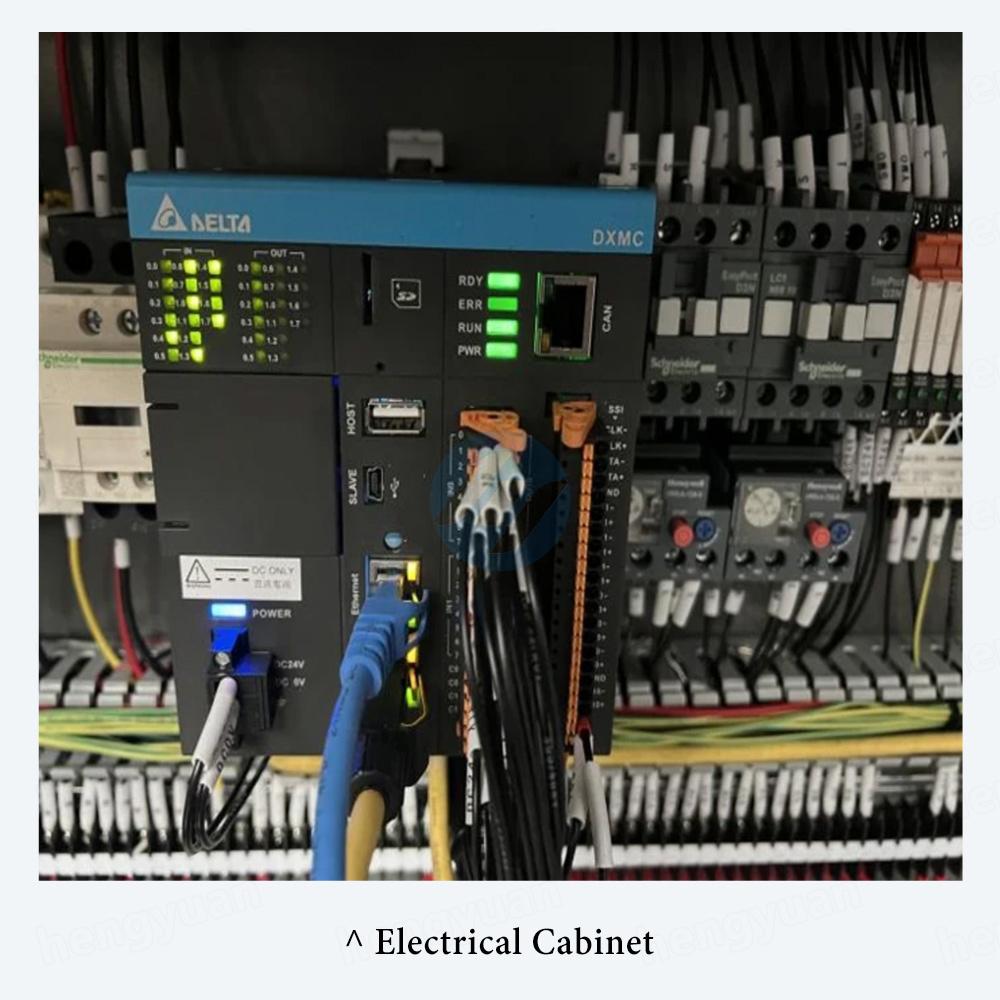

1. Advanced Control System

Equipped with PLC-based microcomputer control and intuitive touchscreen interface for intelligent and simplified operation.

2. Stable Labeling Accuracy

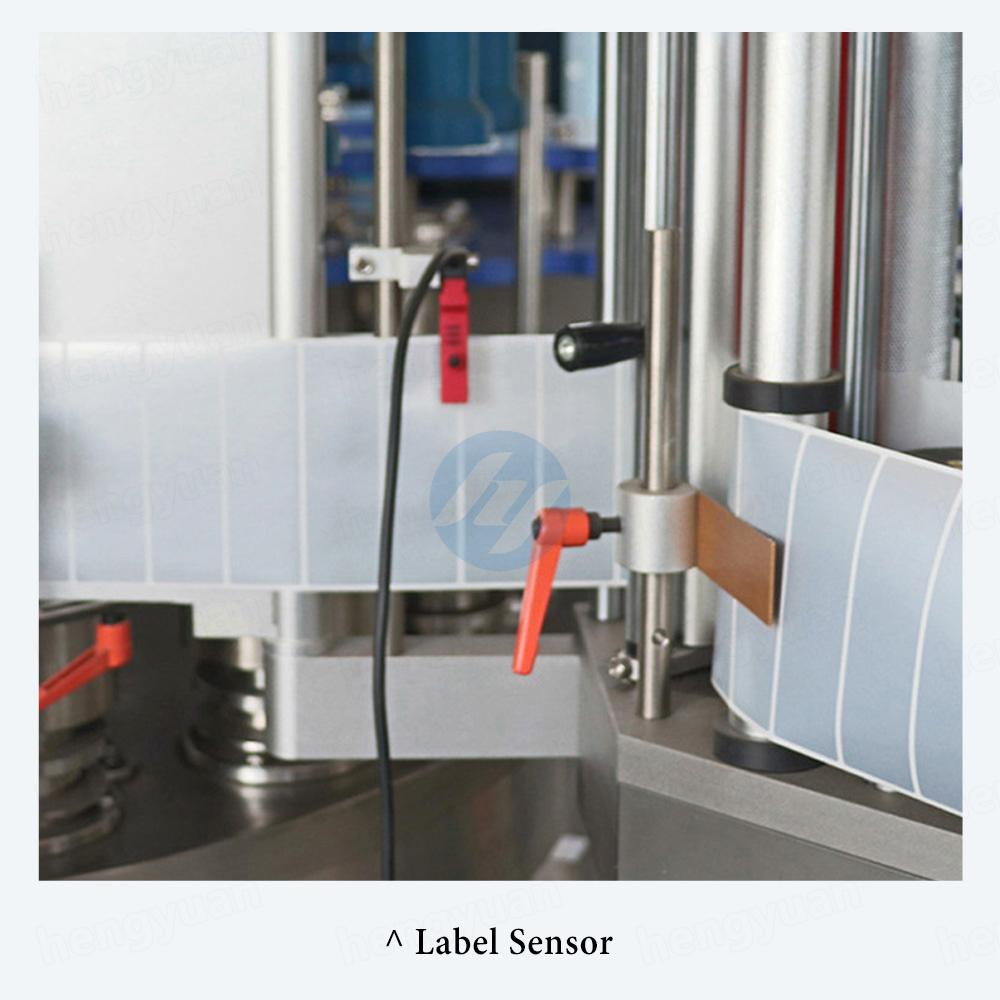

Integrated rotary encoder tracking ensures consistent labeling regardless of speed, unaffected by voltage fluctuations or system damping variations.

3.High-Precision Servo Drive

Features servo systems for high responsiveness, reliability, and exceptionally accurate label placement.

4. Robust and Corrosion-Resistant Build

All machine parts undergo sandblasting and oxidation surface treatment, ensuring rust-free durability with optional custom colors.

5. Accurate Mechanical Positioning

Utilizes bottom mechanical cam positioning for precise product alignment, simplifying design while reducing equipment costs.

6. Automatic Conveyor Adjustment

Automatically adjusts incoming and outgoing product flow for smooth and consistent labeling operation.

7. Flexible Product Compatibility

Customizable to label various container types, including bottles, cans, and drums of different specifications.

8. Continuous High-Speed Performance

Designed for rotary continuous operation, ensuring efficient and high-speed labeling suitable for production line integration.