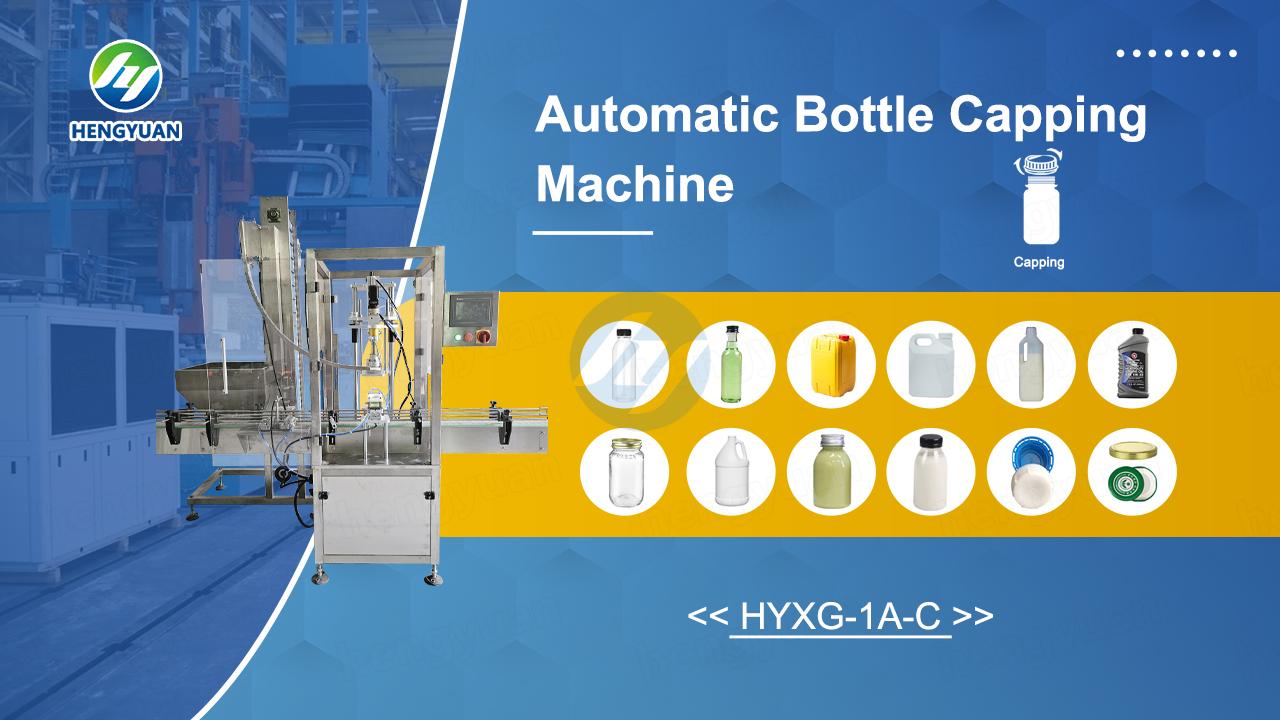

Description

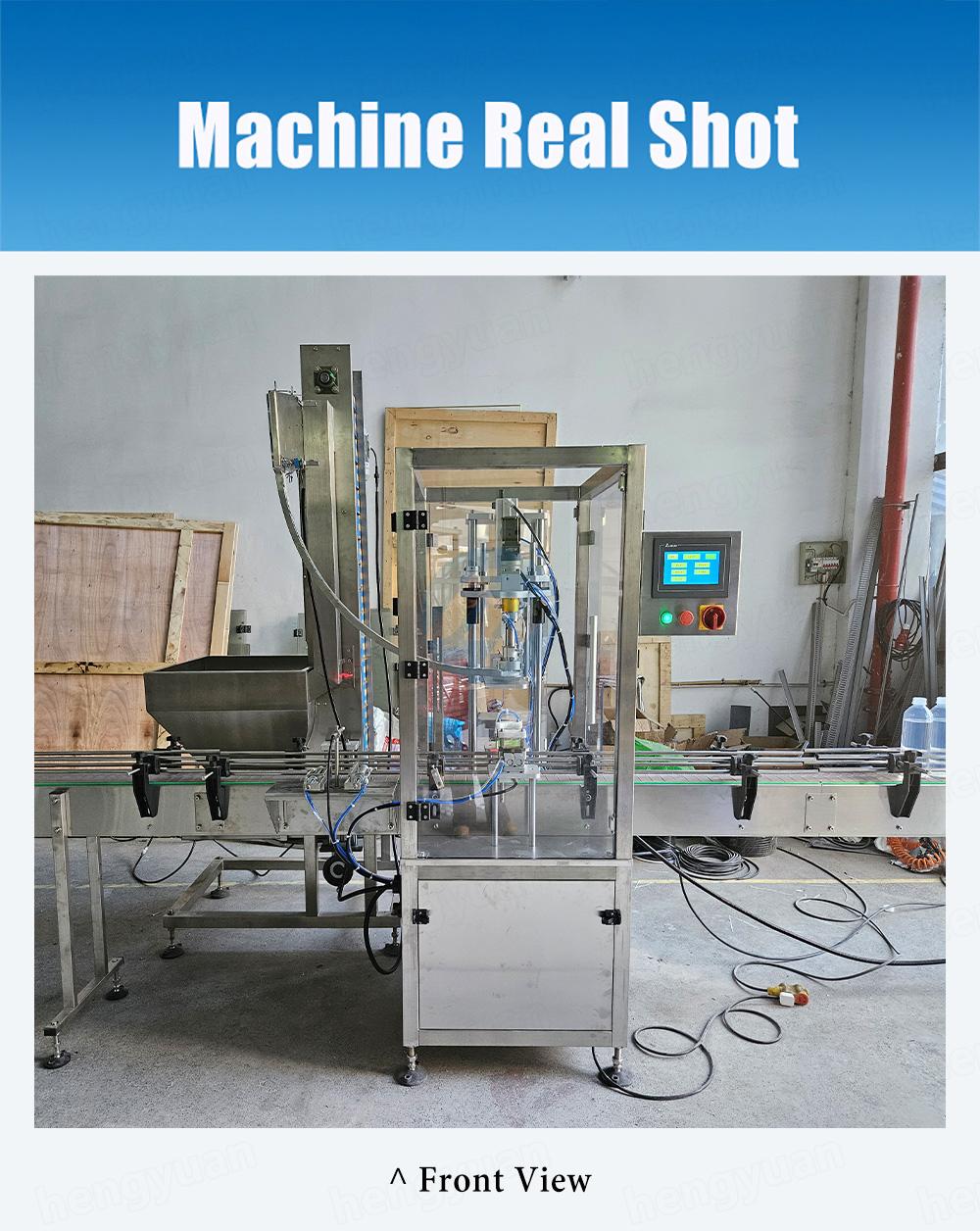

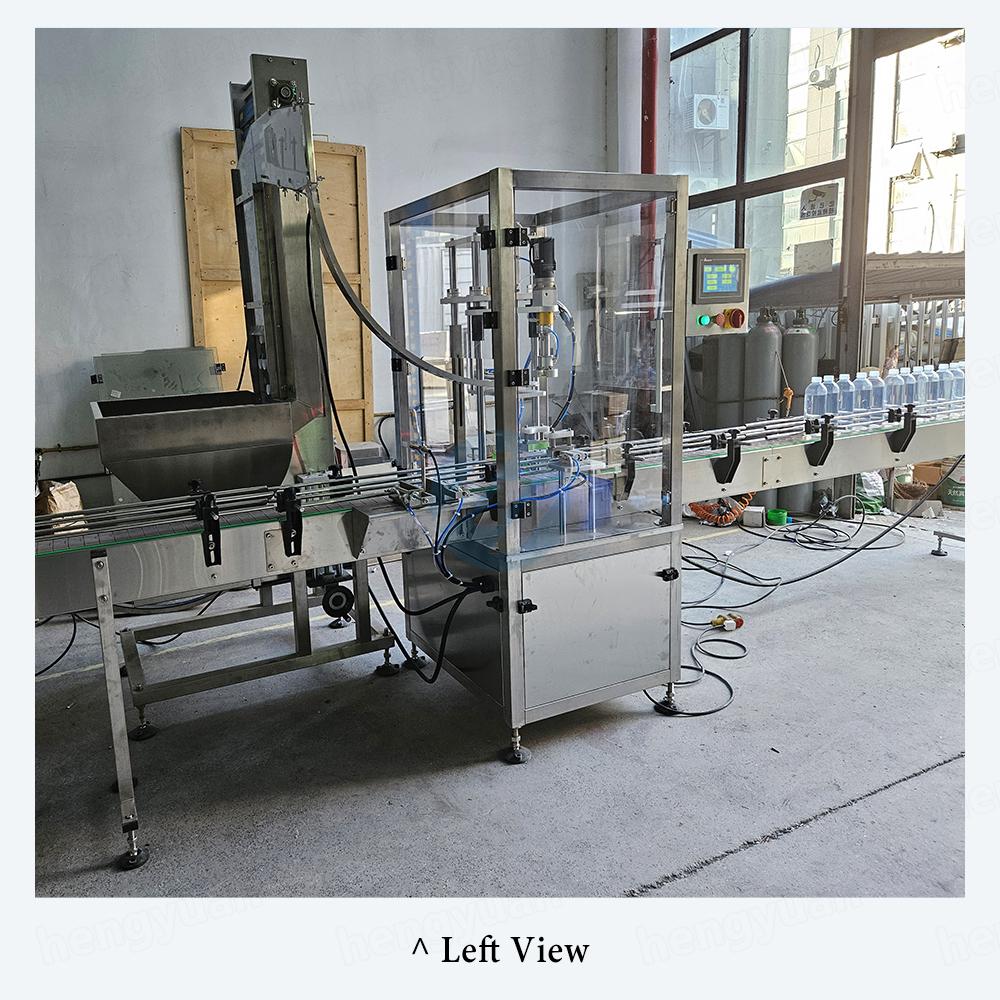

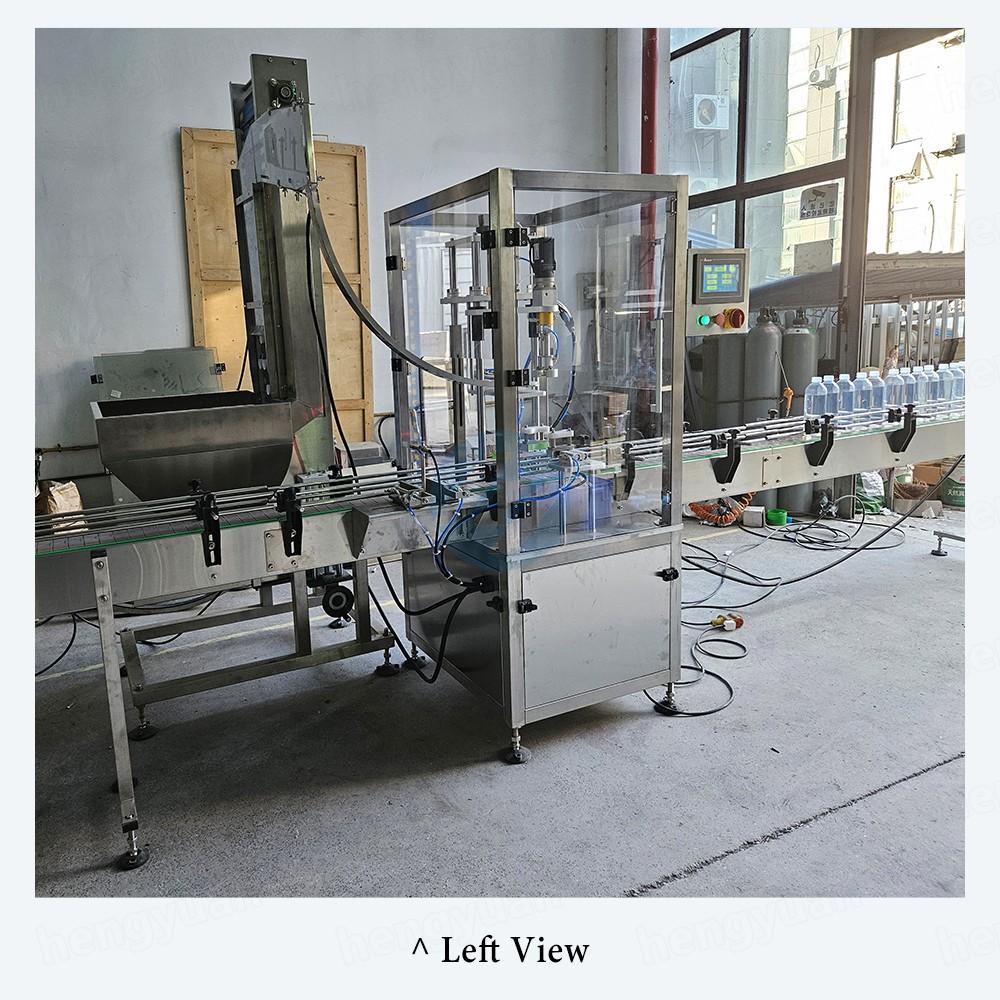

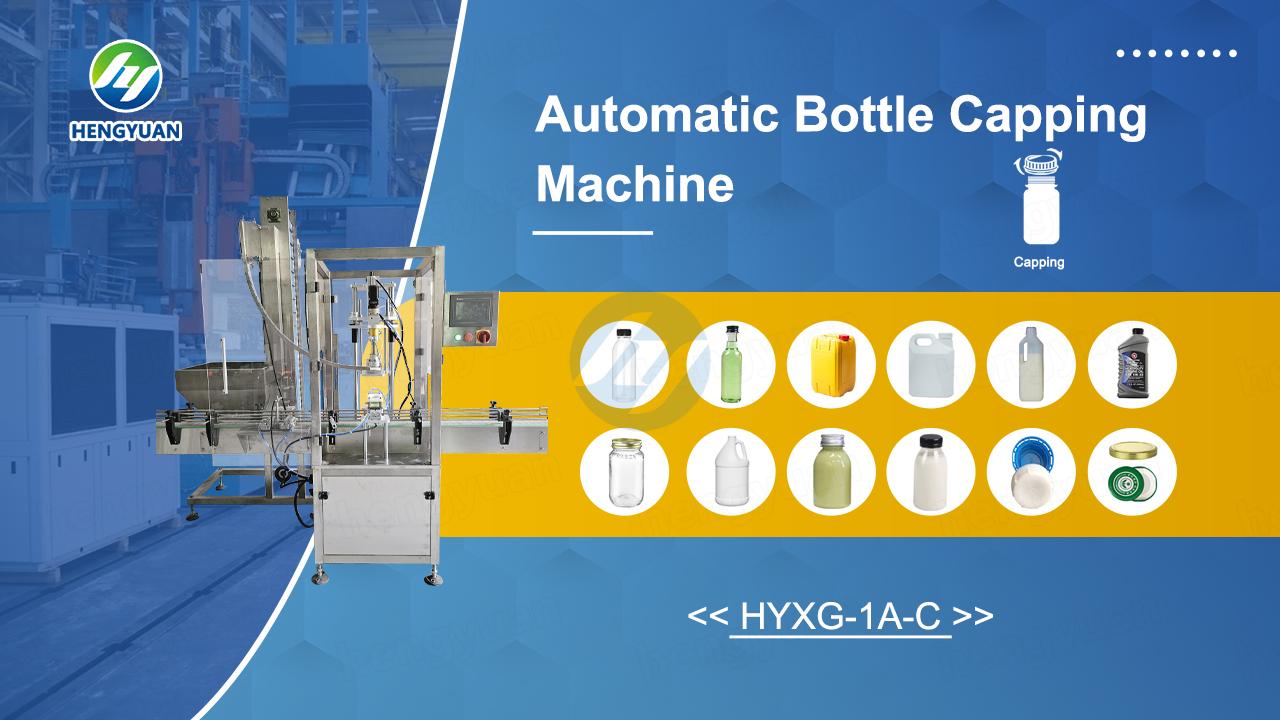

HYXG-1A-C Automatic Single Head Fetching Type

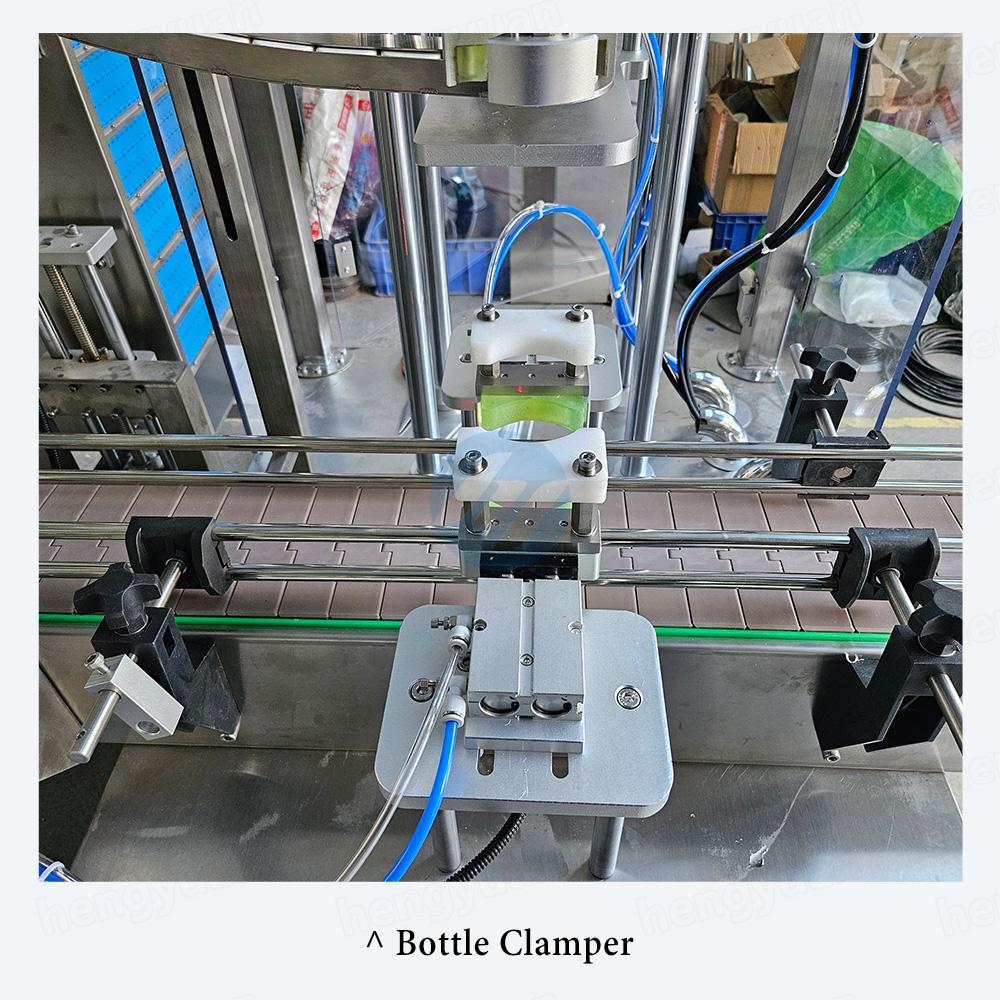

Bottle Capping Machine with Bottle Clamper

Product Introduction

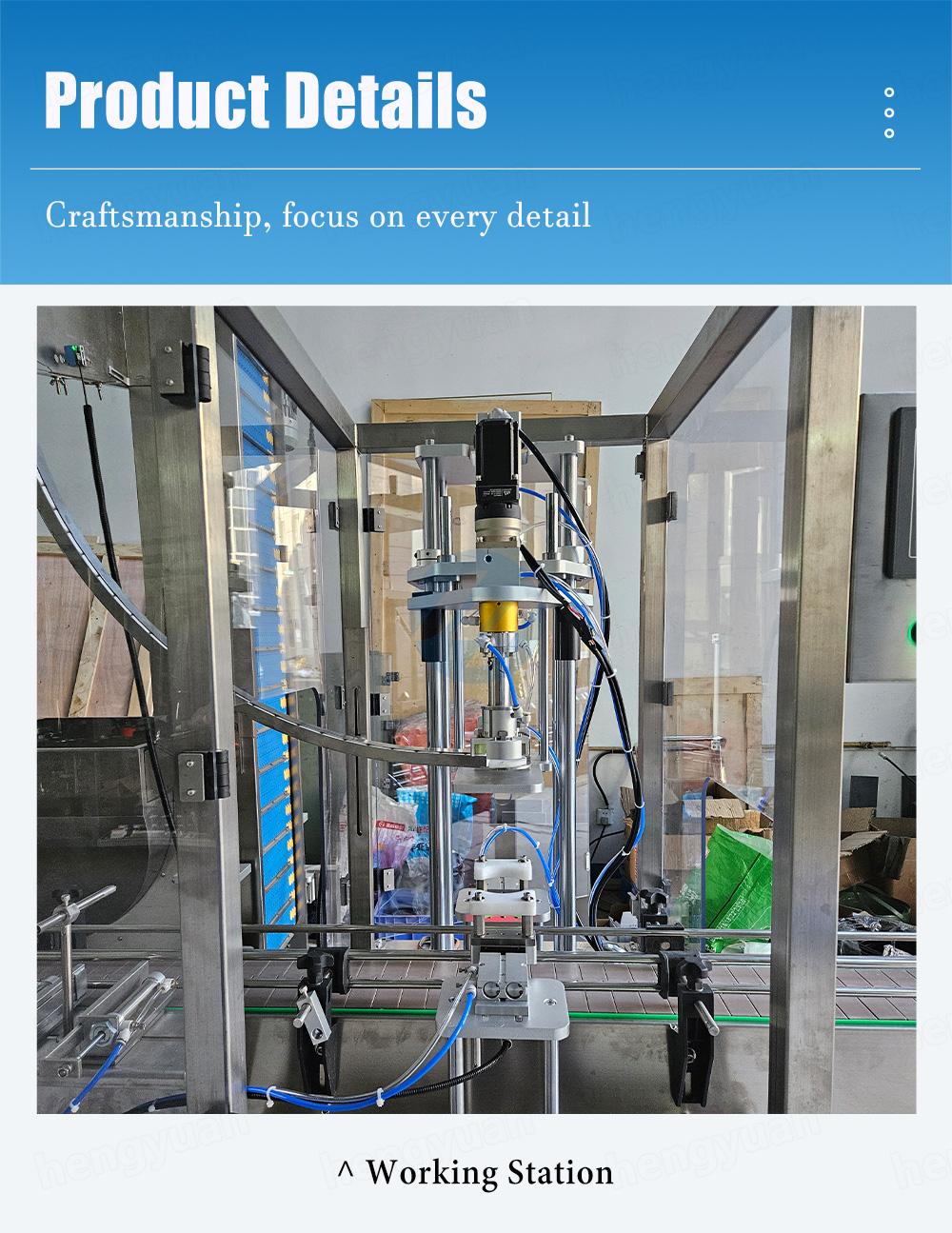

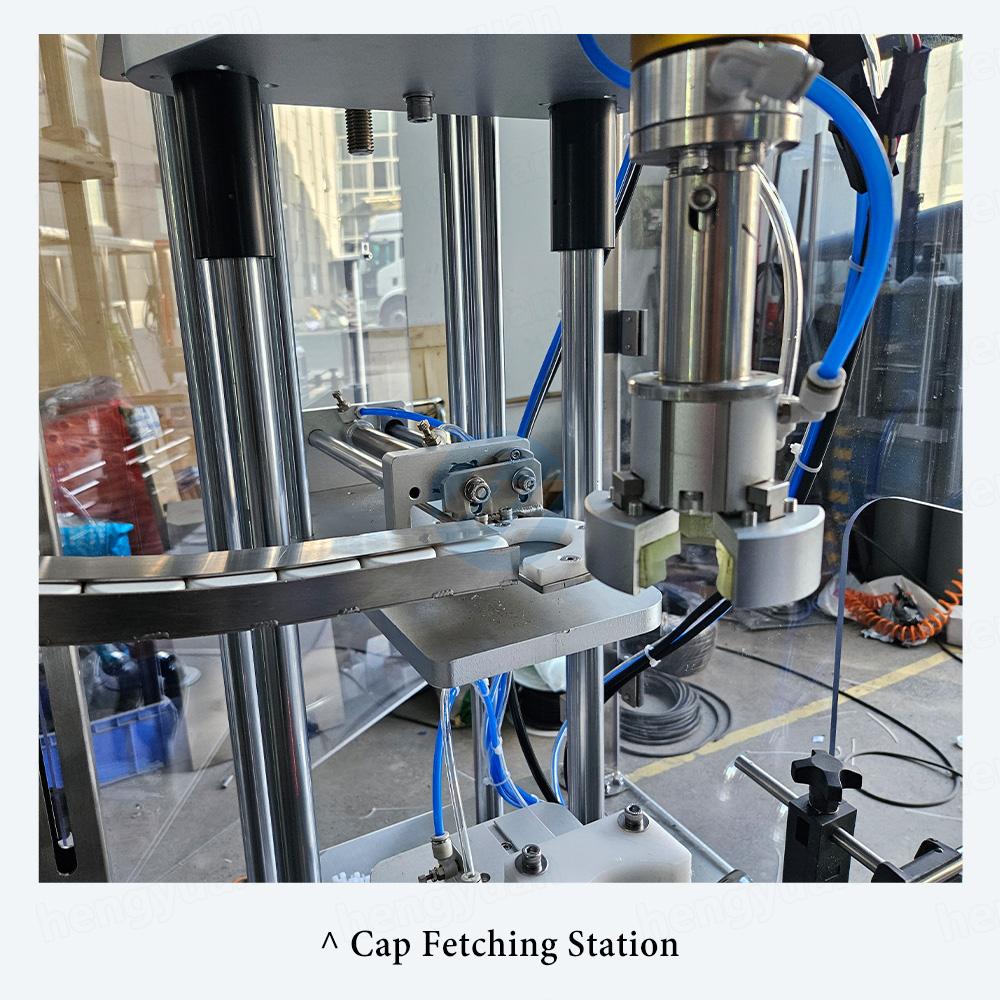

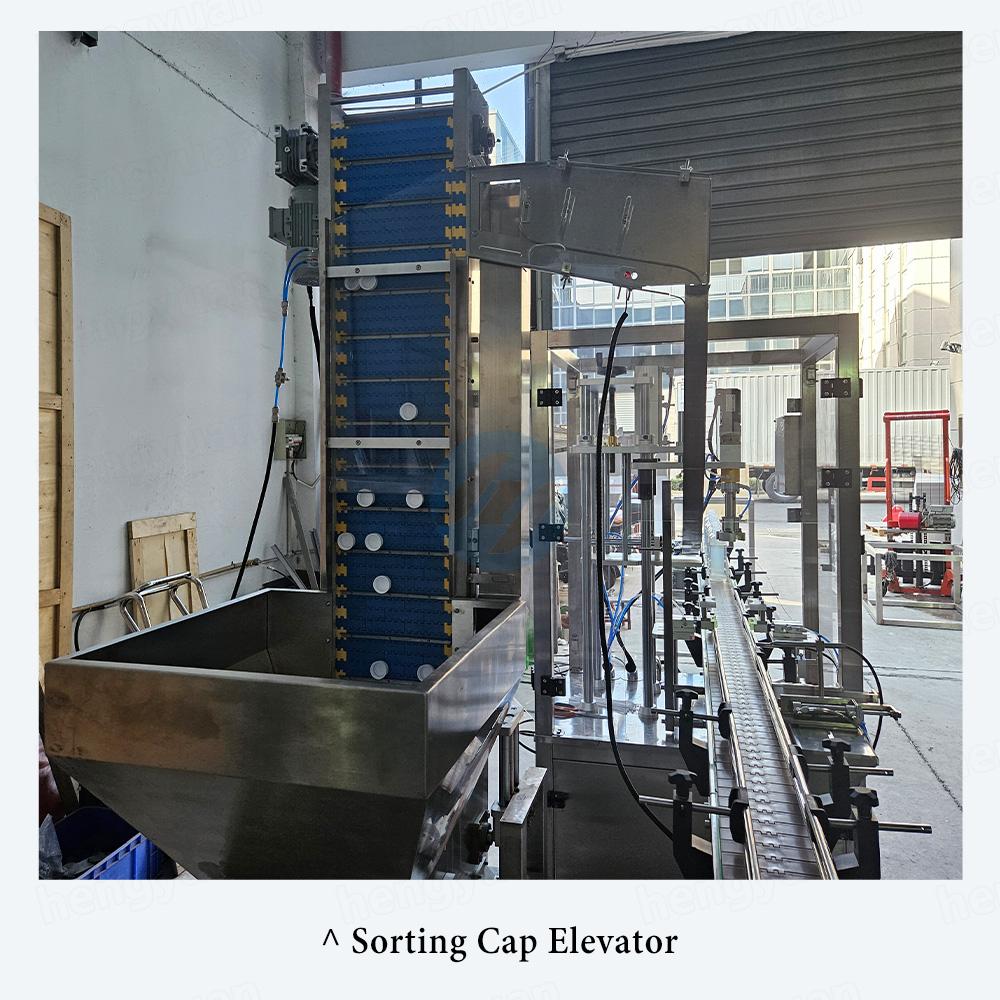

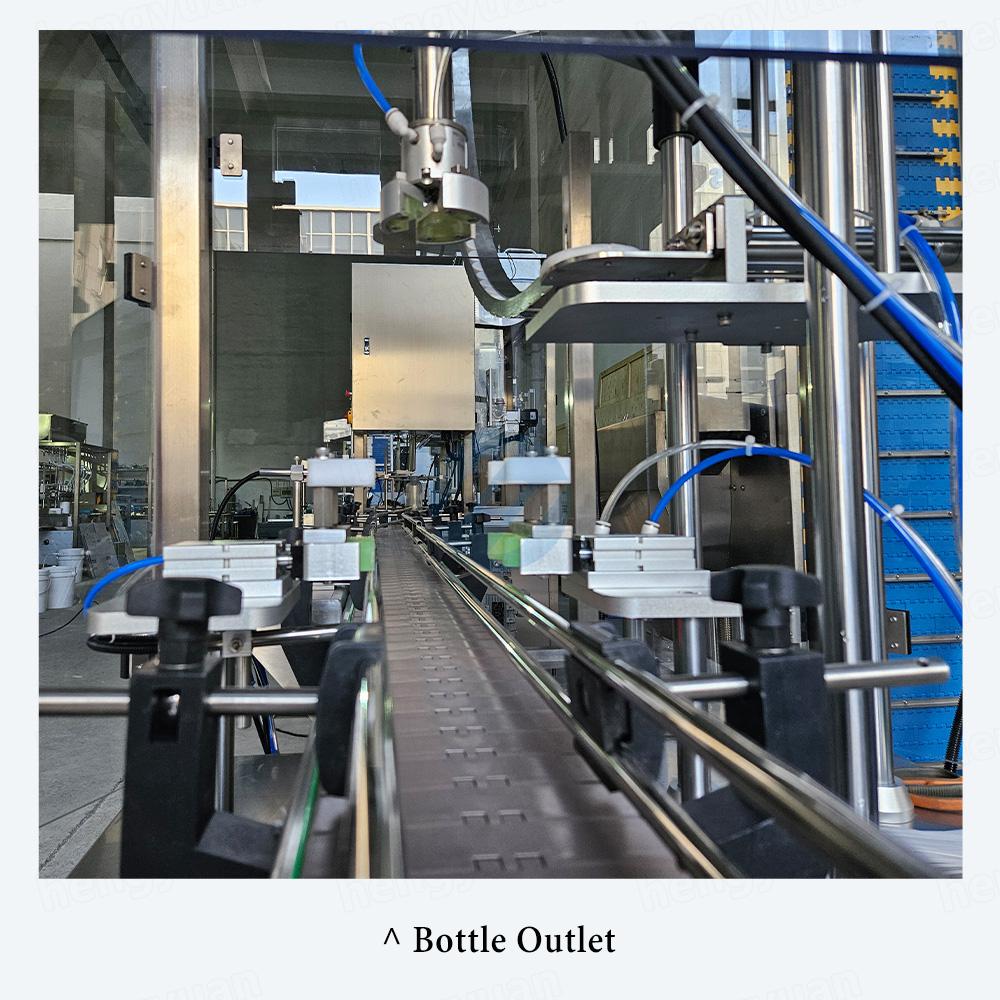

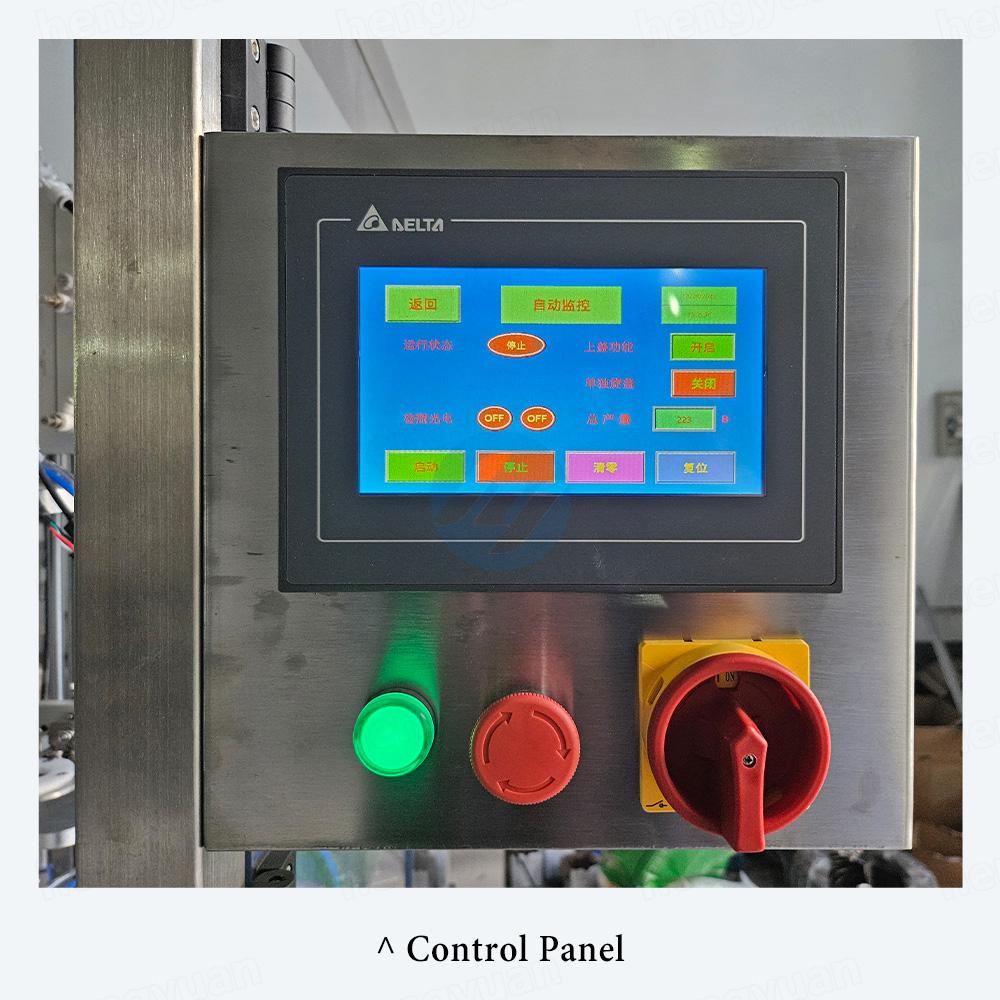

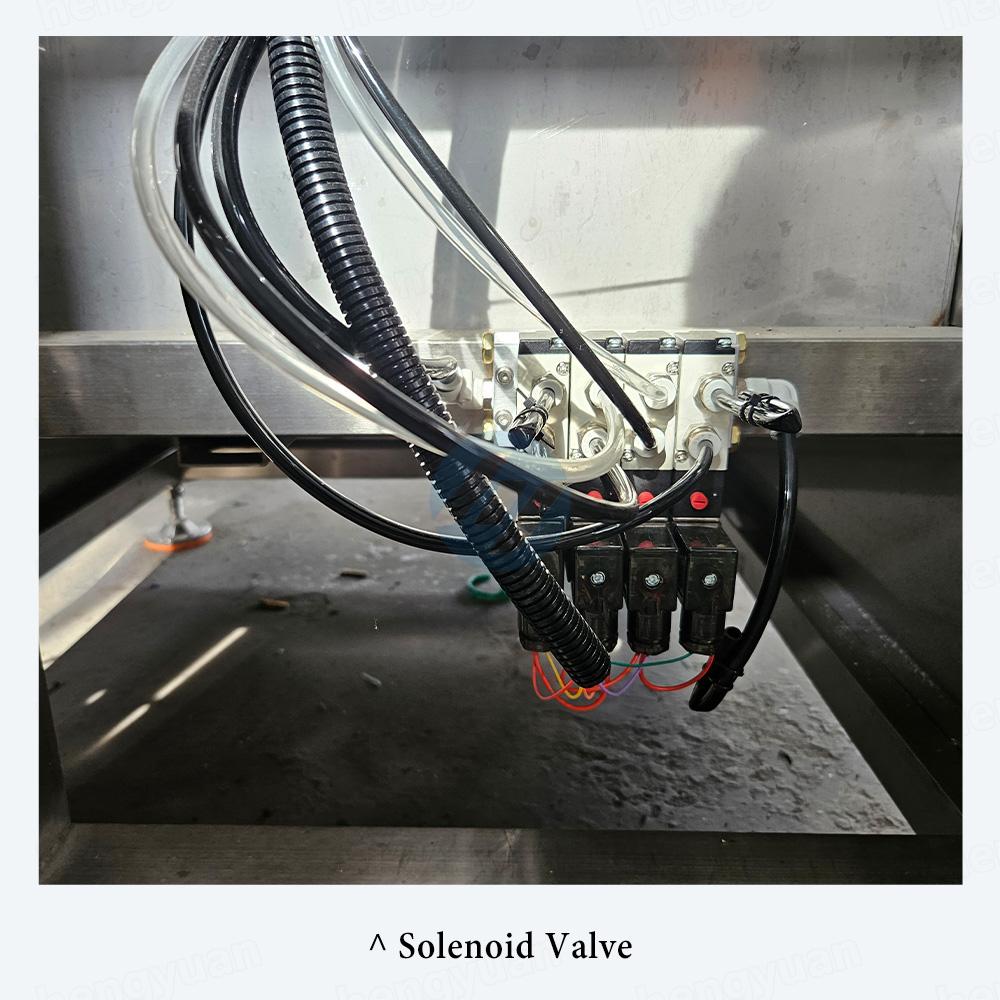

The Automatic Single-Head Bottle and Lid Screwing-On Capping Machine features advanced unscrambling and fetching capabilities, ensuring efficient and protective capping. Controlled by a PLC program and intuitive touch screen, this machine offers seamless automation. Bottles are securely fixed by a pair of servo clamping belts, while the machine automatically arranges, retrieves, and dispatches lids. Guided by a double-acting cylinder lifting stroke, it first securely grasps the lid before capping. Utilizing pneumatic technology, the machine effectively holds the lids, and a clutch in the lid-revolving head prevents damage to the tightly secured lid.

Product Application

HYXG-1A Automatic Single Head Fetching Type Bottle Capping Machine is designed for use with a wide range of containers, including bottles, jerry cans, barrels, gallon buckets, and similar vessels. It is ideal for sealing related products such as lubricants, motor oils, antifreeze coolants, vegetable oils, fertilizers, disinfectants, pharmaceutical and medical alcohols, toilet bowl cleaners, bleaches, and more.

Main Features

1) Boasting an appealing aesthetics, swift and intelligent cover speed, and a high pass rate, this capping machine excels in performance.

2) Its compact and well-thought-out structure allows for seamless integration with other equipment, enhancing versatility and convenience.

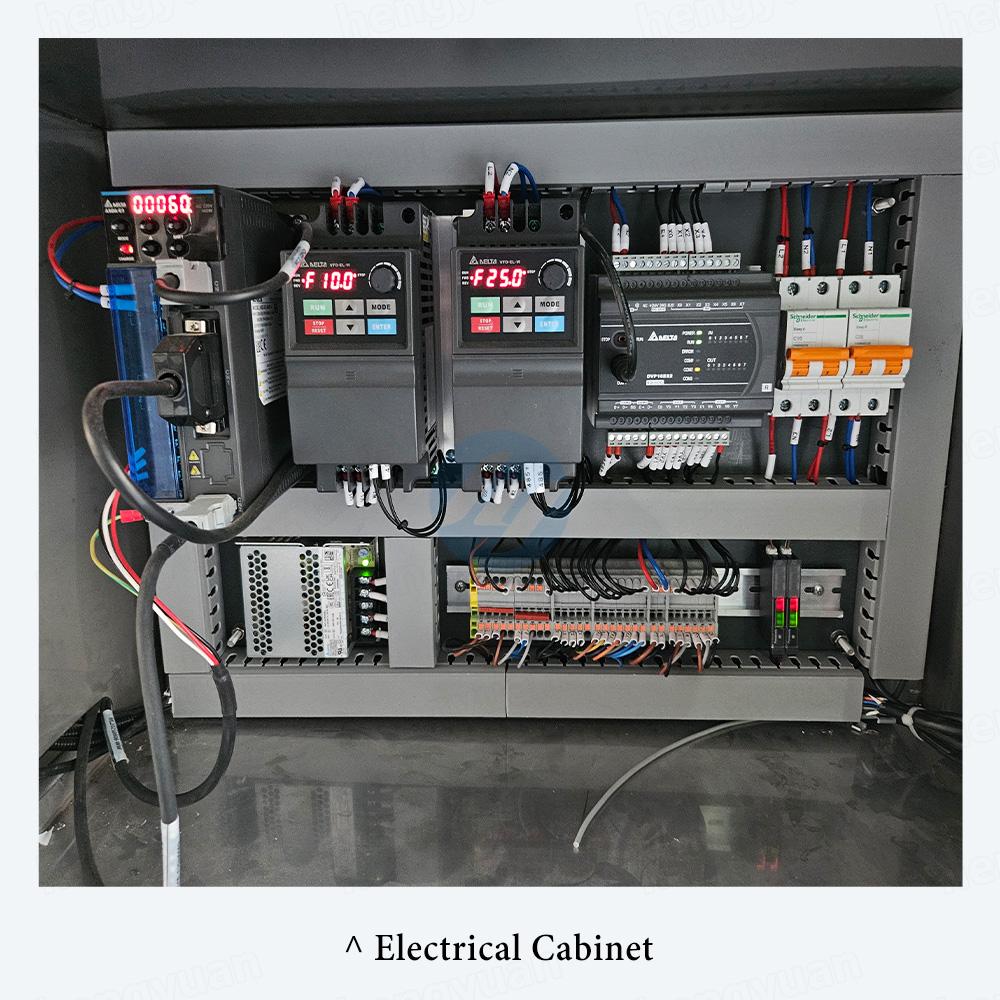

3) Incorporating advanced components from world-renowned brands in pneumatic, electrical, and operational systems, the machine guarantees reliability and durability.

4) The adjustable speed ranges from 0 to 1000 pieces per hour, catering to various production demands.

5) Featuring a novel and innovative design, the machine incorporates intelligent mechanical torque control, facilitating easy operation and adjustment.

6) Suitable for both standalone and inline production, this model offers unparalleled flexibility and efficiency.

Bottle Capping Machine with Bottle Clamper

Product Introduction

The Automatic Single-Head Bottle and Lid Screwing-On Capping Machine features advanced unscrambling and fetching capabilities, ensuring efficient and protective capping. Controlled by a PLC program and intuitive touch screen, this machine offers seamless automation. Bottles are securely fixed by a pair of servo clamping belts, while the machine automatically arranges, retrieves, and dispatches lids. Guided by a double-acting cylinder lifting stroke, it first securely grasps the lid before capping. Utilizing pneumatic technology, the machine effectively holds the lids, and a clutch in the lid-revolving head prevents damage to the tightly secured lid.

Product Application

HYXG-1A Automatic Single Head Fetching Type Bottle Capping Machine is designed for use with a wide range of containers, including bottles, jerry cans, barrels, gallon buckets, and similar vessels. It is ideal for sealing related products such as lubricants, motor oils, antifreeze coolants, vegetable oils, fertilizers, disinfectants, pharmaceutical and medical alcohols, toilet bowl cleaners, bleaches, and more.

|

Technical Parameters |

|

|

Capping capacity |

600-1000bottles/hour according to bottle and lid sizes |

|

Applicable cap diameter |

20-70mm customized according to caps |

|

Suitable bottle diameter |

customized according to bottle sample |

|

Suitable for bottle height |

customized according to bottle sample |

|

Total Power |

1.5kw |

|

Power supply |

AC380V/220V/110V, Single phase or three phased, globally customized |

|

Air supply |

0.5-0.7Mpa |

1) Boasting an appealing aesthetics, swift and intelligent cover speed, and a high pass rate, this capping machine excels in performance.

2) Its compact and well-thought-out structure allows for seamless integration with other equipment, enhancing versatility and convenience.

3) Incorporating advanced components from world-renowned brands in pneumatic, electrical, and operational systems, the machine guarantees reliability and durability.

4) The adjustable speed ranges from 0 to 1000 pieces per hour, catering to various production demands.

5) Featuring a novel and innovative design, the machine incorporates intelligent mechanical torque control, facilitating easy operation and adjustment.

6) Suitable for both standalone and inline production, this model offers unparalleled flexibility and efficiency.

7) Equipped with a constant torque capping head, pressure adjustments are straightforward and effortless.