Description

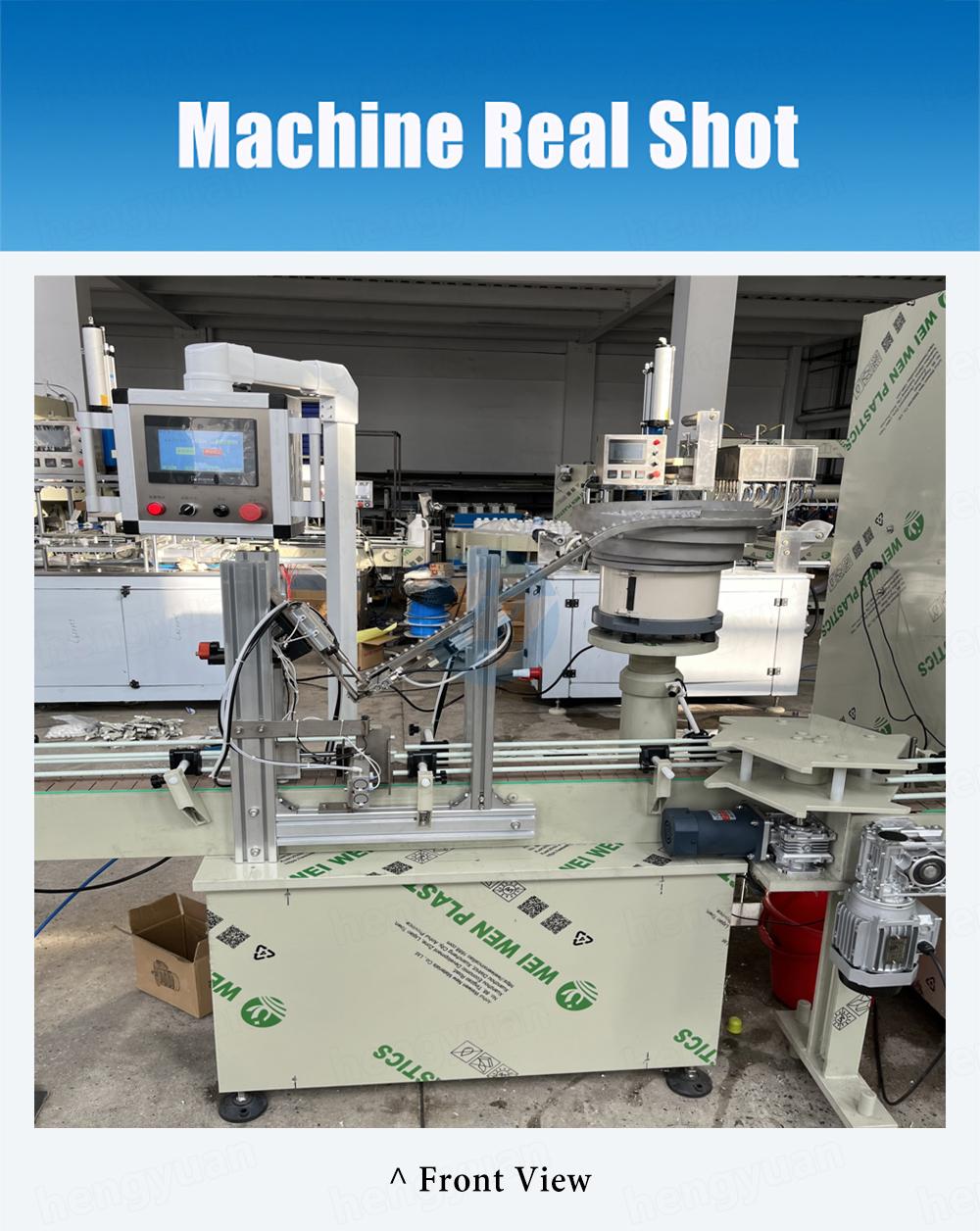

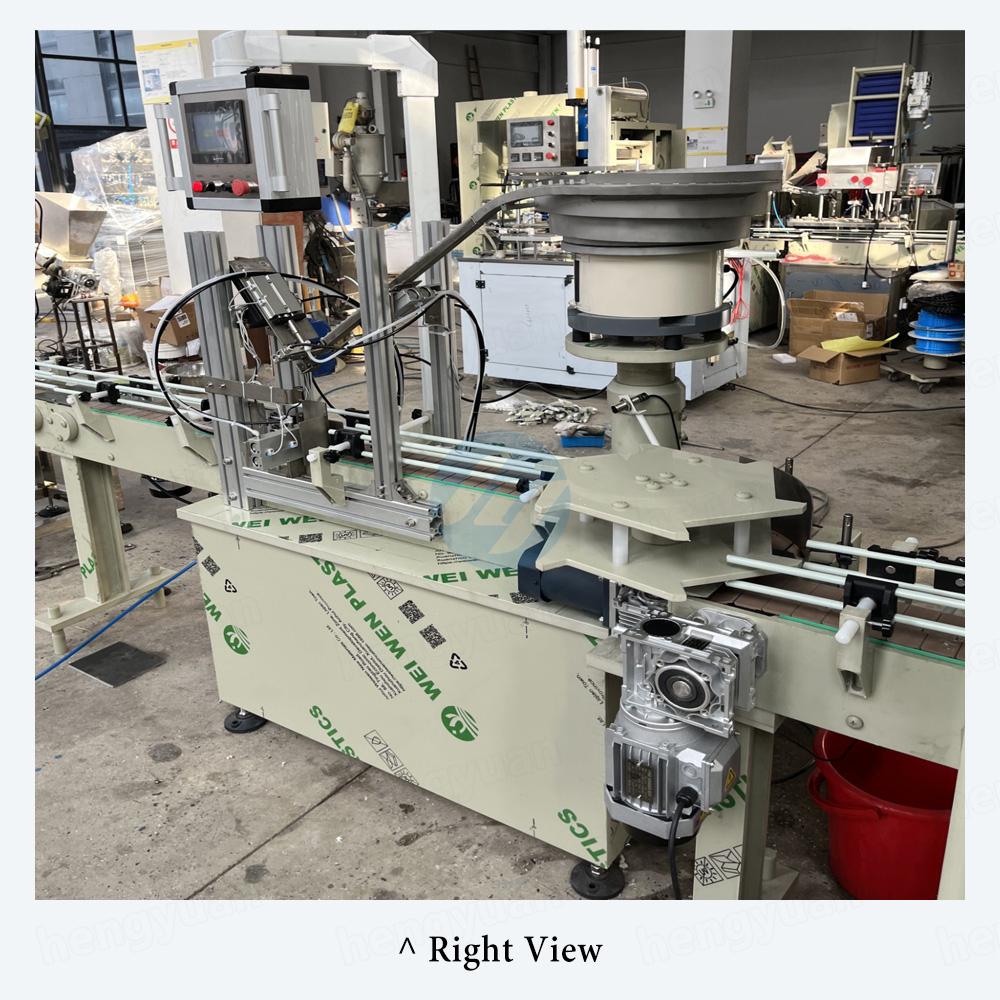

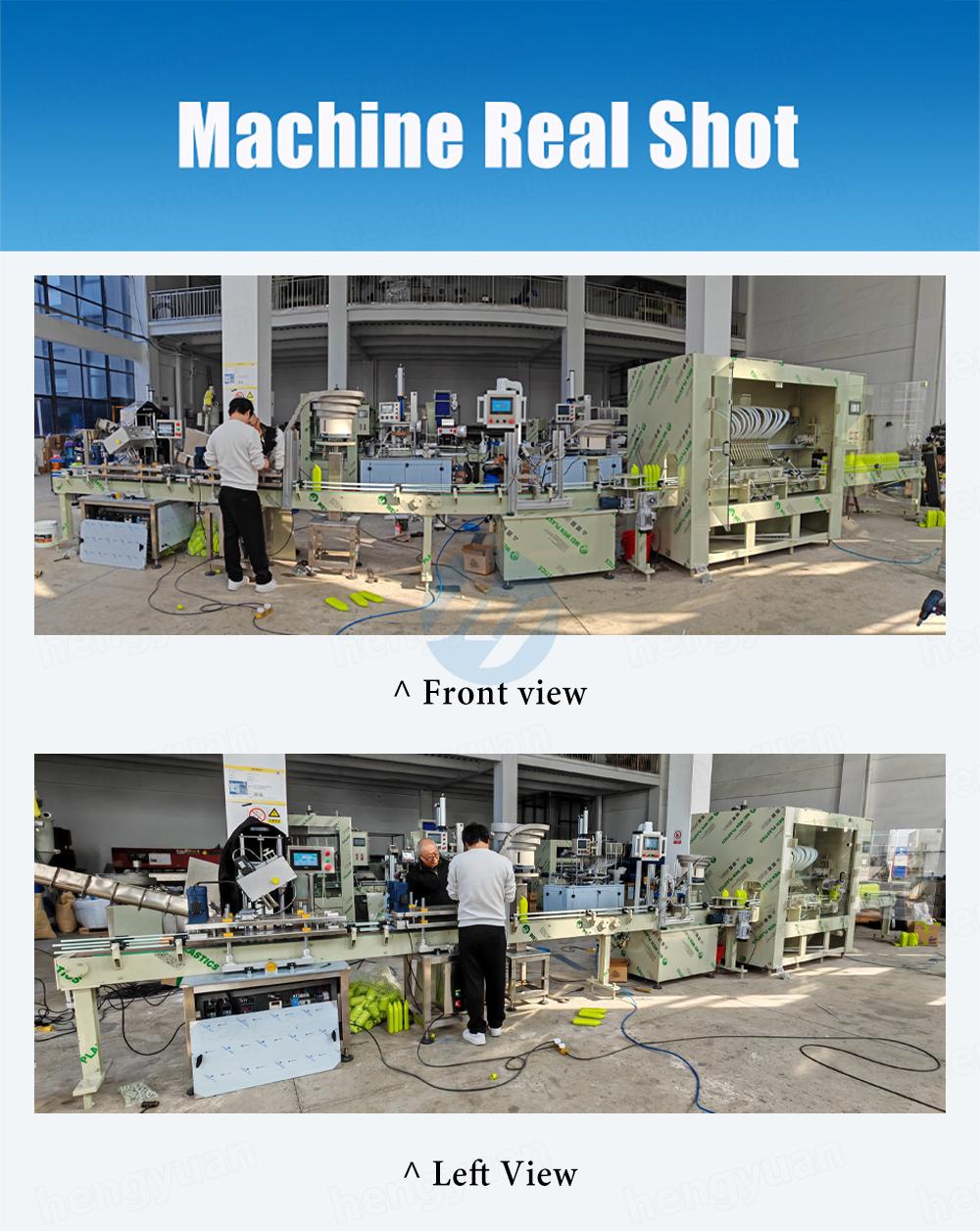

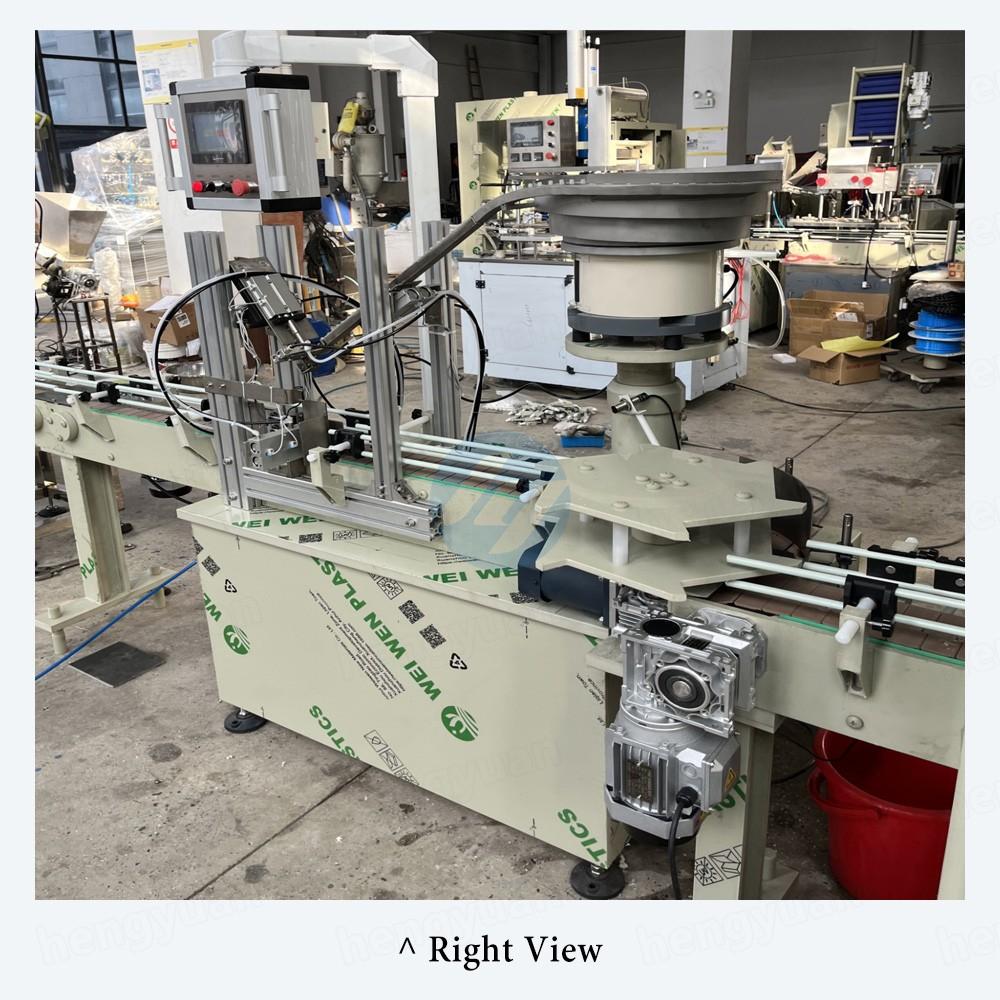

HYIP-1A-X Automatic Tilt Bottle Plugging Capping Machine for Toilet Bowl Cleaner

Introduction

Automatic Tilt Bottle Plugging Capping Machine is a new product developed on the base of the latest technology, using air cylinder to insert plug into the toilet bowl cleaner bottle. The bottle plugging machine adopts PLC to combine the actions. And the parameters are set in touch screen. The mechanical parts are customized to suit for bottles with different sizes. Its most prominent feature is that it is customized for tilt bottle. According to plug shapes and sizes, the plugging machine can be equipped with suitable plug sorting device, such as vibrating bowl. It can be used for medium and big-batch production.The capping machine is widely used in daily chemical industries.

Application

Toilet bowl cleaner tilt bottle plugging machine, Tilt neck bottle plugger for toilet bowl cleaner, Angled bottle plug capping machine, Inclined spout bottle capping equipment, Tilted bottle plug tightening machine, Automatic tilt bottle plug inserting machine for liquid cleaner, Leak-proof plug capper for tilted cleaner bottles, PLC control tilt bottle plugging machine, High-speed plugging machine for angled bottles, Toilet cleaner packaging plugging machine, etc.

|

Technical Parameters |

|

|

Capping capacity |

0-2500bottles/hour according to bottle and lid sizes |

|

Applicable plug |

customized according to sample |

|

Suitable bottle diameter |

20-100mm, special sizes can be customized according to bottle sample |

|

Suitable for bottle height |

80-280mm, special sizes can be customized according to bottle sample |

|

Total Power |

0.8Kw |

|

Power supply |

AC220V/110V, Single phase, can be customized globally |

|

Air supply |

0.5-0.7Mpa |

Main Features

1) Simple linear structure and pneumatic plugging capping, excellent capping effect and wide customization adaptability, easy in installation and maintenance.

2) Use pneumatic and single head to inserting plug with bottles, high efficiency and good effect.

3) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

4) High speed adjustable from 0-2500pcs per hour.

5) Running in a high automation and intelligent, no pollution.

6) Economic price and suitable for both medium and big capacity production.