Description

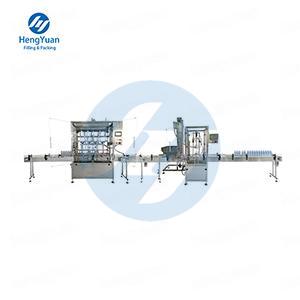

Liquid Filling Machine with Servo Motor Diving

Product Introduction

The semi-automatic weighing type filling machine has the advantages of high accuracy when filling liquid 5-30kg. It is matched with the servo motor diving filling to reduce the liquid foam, touch screen and PLC to control filling. Operation process for machine modification: manual bucket placement, foot switch, automatic filling machine, manual removal of finished products. It is widely used in the lubricant, cooking oil, cosmetics, daily chemical industries.

Product Application

20L Lubricant pail filling machine, 5kg motor oil filling machine, 20kg paint weighing filler, 10L wine weghing dispensing machine, 30kg vegetable oil pet bottles filling machine, cooking oil jerry cans filler, liquid fertilizer dispensing machine, etc.

HYWF-30S-2S Semi-automatic Weighing Dosing Liquid Filling Machine

Main Features

Technical Parameters

Filling range

5kg-30kg

Filling nozzle outer diameter

Customized according to bottle mouth

Filling accuracy

≤±0.5%

Filling speed

150~400 bottles/minute according to bottle filling volume

Control method

Pedal

Working air pressure

0.4-0.6Mpa

Operation voltage

220V or 110V, Single phase.

Electricity consumption

2.0Kw

Machine size

100*90*140cm

Weight

180Kg

1) The system adopts weighing filling, which has high measuring accuracy and is not affected by materials.

2) The feeding valve composed of fast and slow feeding can not only improve the filling speed but also improve the filling accuracy.

3) The measurement range is large, and the measurement error is less than 10g/barrel.

4) The filling head adopts anti-drip device, and the filled material has no bubbles and good effect.

5) No leakage, no pollution: optional Teflon and mechanical seal, work without leakage, flow parts 304 stainless steel material, food hygiene.

6) Easy to wash: pour clean water into the equipment and wash it with high-speed circulating water, which is convenient and sanitary.