Description

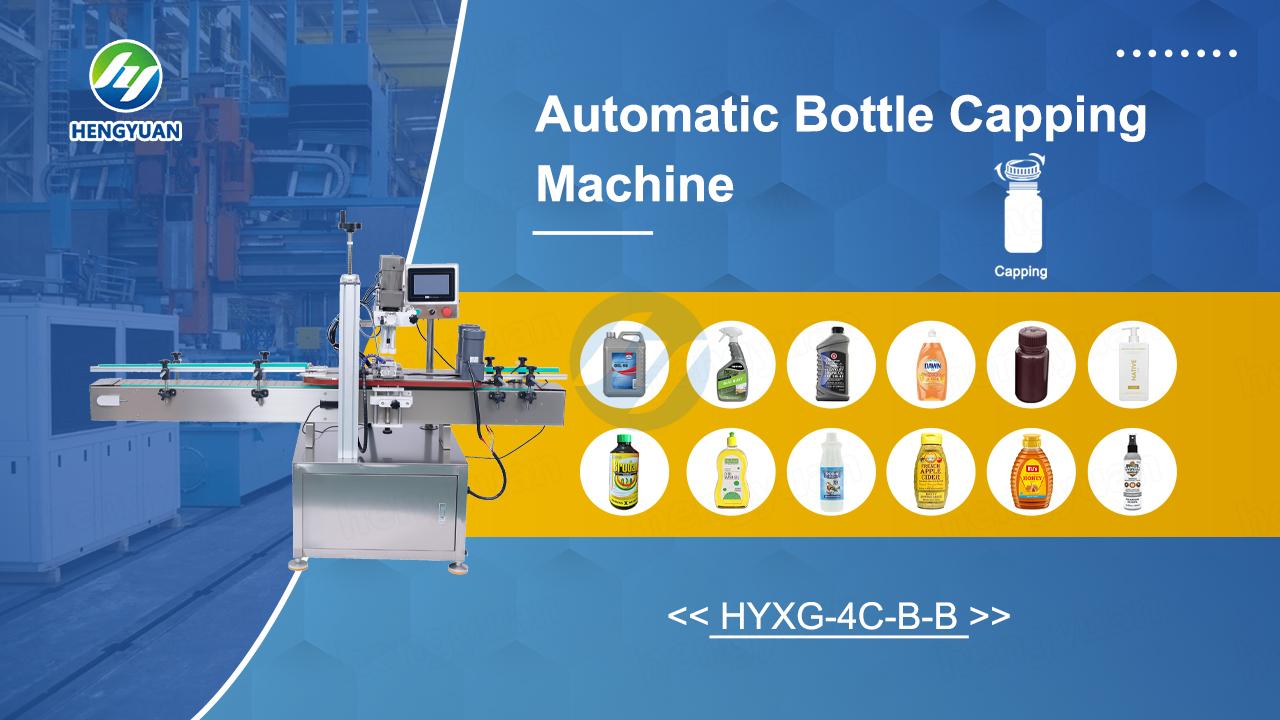

HYXG-4C-B-B Automatic Four‑Wheel Bottle Capping Machine

Brief Introduction:

This economical four-wheel clamping capping machine is designed with advanced technology to securely grip and screw caps onto containers. Controlled by a PLC system with a touchscreen interface, it offers flexible parameter adjustment and easy operation. It is matched with bottle clamping belts to make bottles stable and easy to control to stop or run. The machine features fully adjustable mechanical components to accommodate bottles of various sizes and shapes, making it suitable for multi‑product lines without requiring additional change parts.A customizable cap sorting system—including options such as vibrating bowls, centrifugal sorters, and elevated lid feeders—can be integrated based on lid type. Ideal for small to medium‑batch production, the machine meets GMP standards and is designed for easy disassembly, cleaning, and maintenance.

It is widely used across the pharmaceutical, chemical, food, beverage, oil, and agrochemical industries for reliable and adaptable capping applications.

|

Technical Parameters |

|

|

Capping capacity |

Up to 1800‑3000 bottles/hour (varies with bottle and cap size) |

|

Cap Diameter Range |

15‑60 mm (customizable based on provided cap samples) |

|

Bottle Diameter Range |

20‑100 mm (special sizes available upon request) |

|

Bottle Height Range |

50‑300 mm (special heights available upon request) |

|

Total Power |

0.6 kW |

|

Power Supply |

AC 220V/110V, single‑phase (global voltage options available) |

|

Air Supply |

0.5‑0.7 MPa |

|

Net Weight |

180 kg |

|

Dimensions (L × W × H) |

200 × 70 × 130 cm |

1. Automatically sorts and installs flat‑top plastic/metal screw‑on caps, lug caps, press‑on caps, pull‑off lids, and flip‑top lids.

2. Supports manual cap placement for specialized closures, including tube caps, pump dispensers, spray heads, and trigger‑type caps.

Product Features

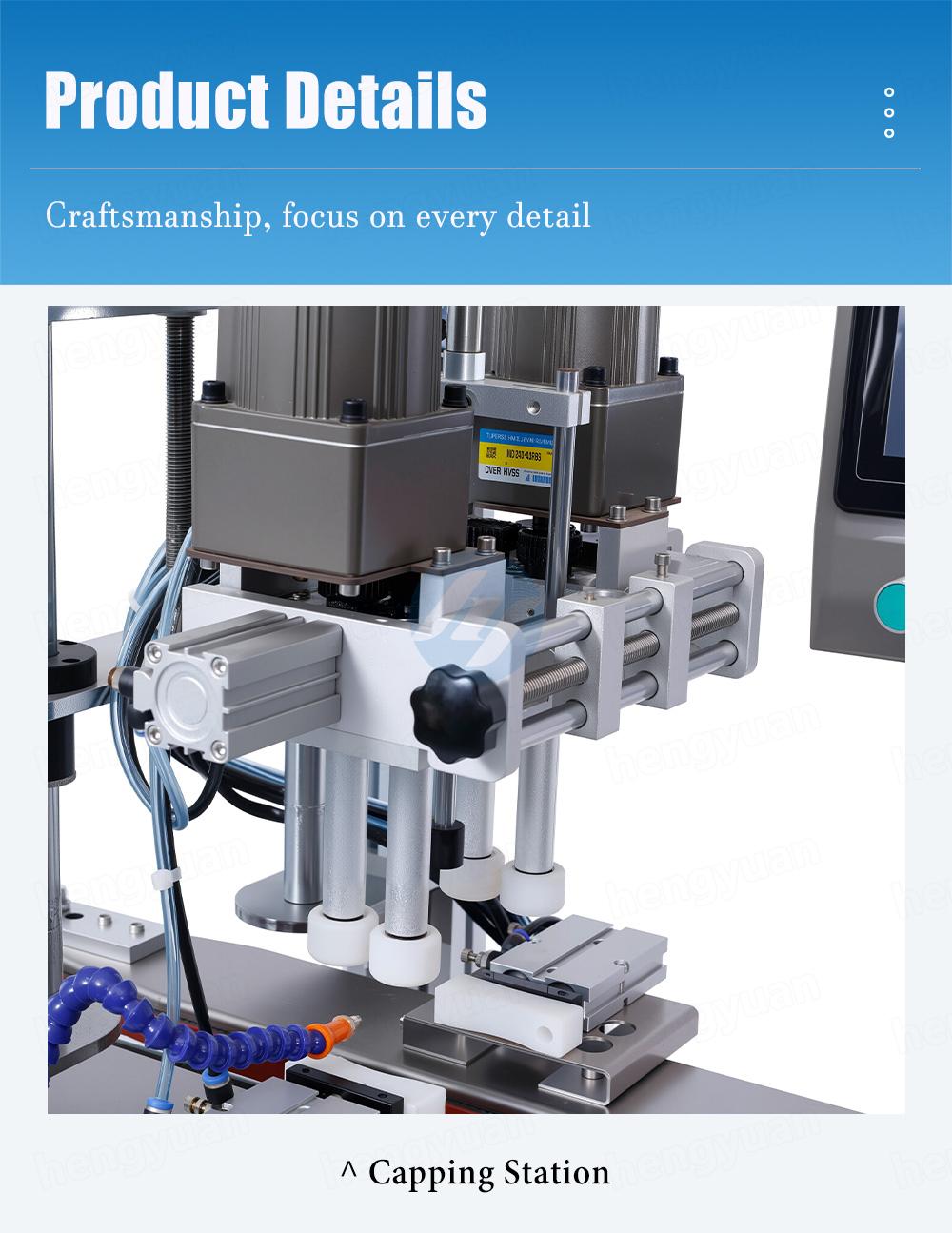

1. Robust Linear Structure & Versatile Four-Wheel Capping

The simple yet durable linear design ensures smooth bottle handling, while the advanced four‑wheel clamping mechanism provides secure and reliable sealing across diverse cap and bottle types, enhancing both adaptability and ease of installation and maintenance.

2. Premium Component Integration

Equipped with internationally recognized pneumatic, electrical, and control components, guaranteeing consistent performance, high reliability, and extended service life in demanding production environments.

3. Adjustable High-Speed Operation

Offers flexible capping speeds ranging from 1,800 to 3,000 bottles per hour, enabling efficient output that can be tailored to match specific production requirements.

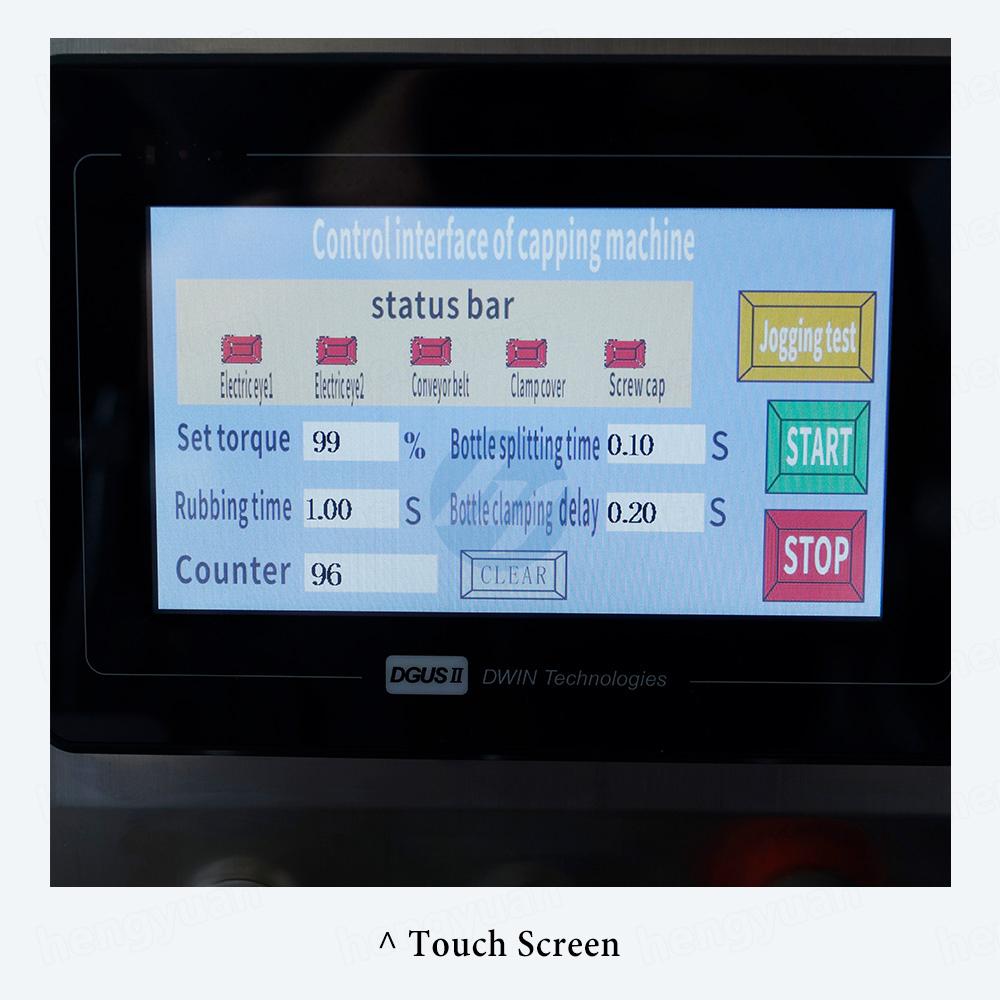

4. Intelligent and Clean Automation

Operates with full PLC-based automation and intuitive touchscreen controls, ensuring contamination-free, intelligent operation that reduces manual intervention while maintaining high standards of hygiene.

5. Cost-Effective for Small to Medium Batches

Designed to deliver exceptional value, the machine combines affordable investment with reliable performance, making it an ideal choice for small and mid-sized production lines seeking quality automation.

6. Compact Footprint and Easy Integration

With a compact design measuring 200 × 75 × 135 cm and weighing only 180 kg, the system integrates seamlessly into existing lines while allowing simple reconfiguration and quick changeovers.