Description

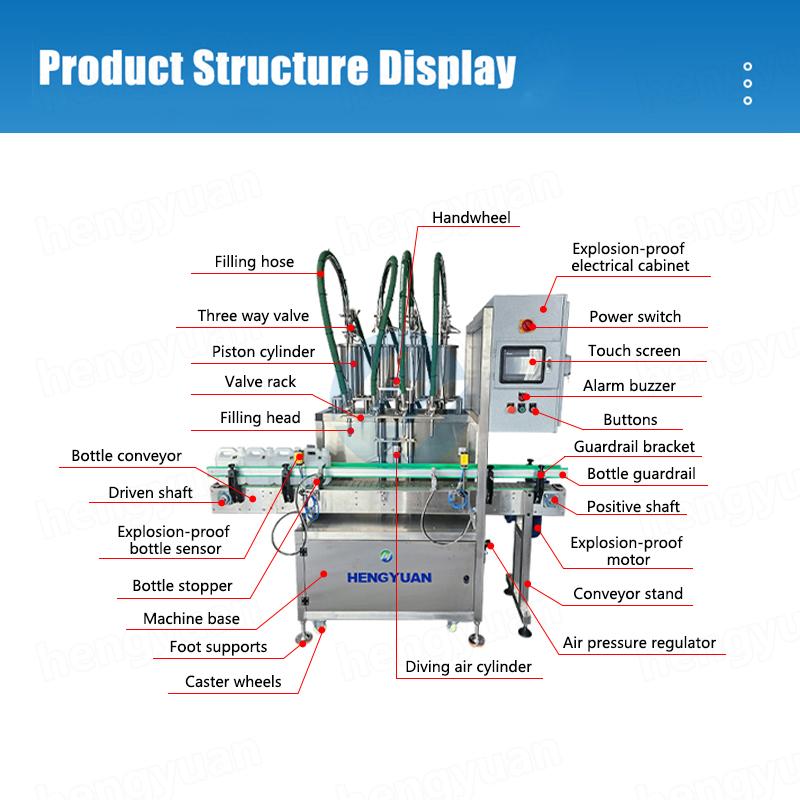

Pneumatic Piston Filling Machine

Product Introduction

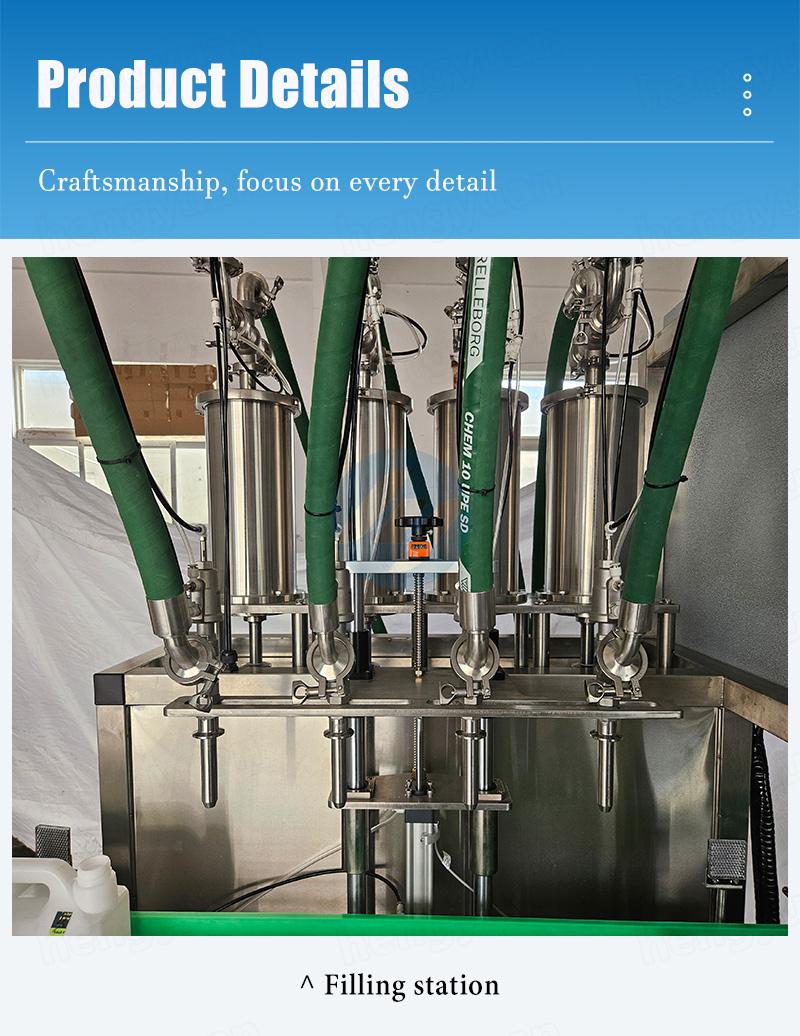

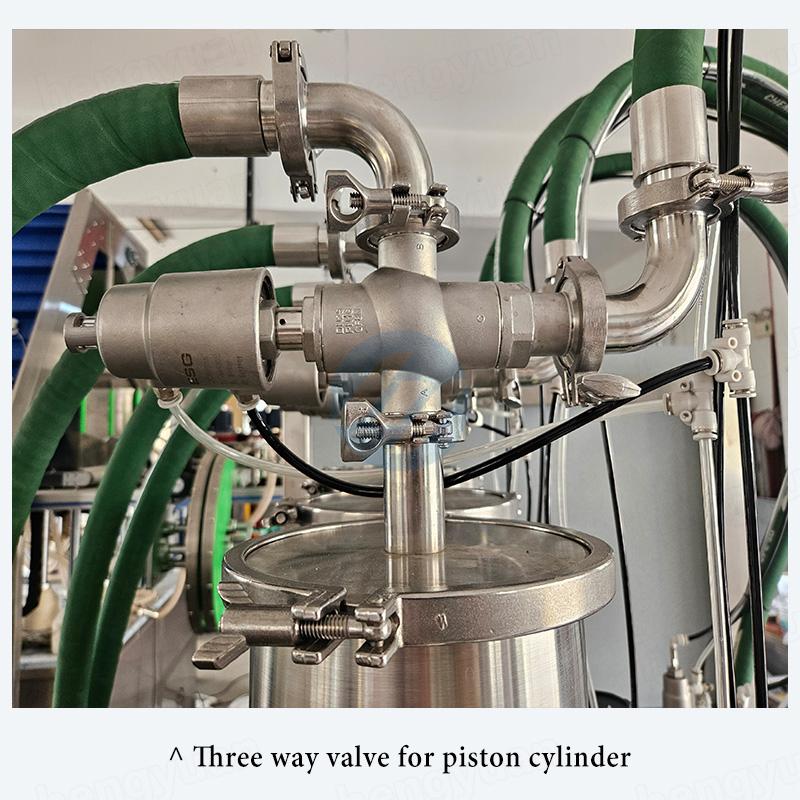

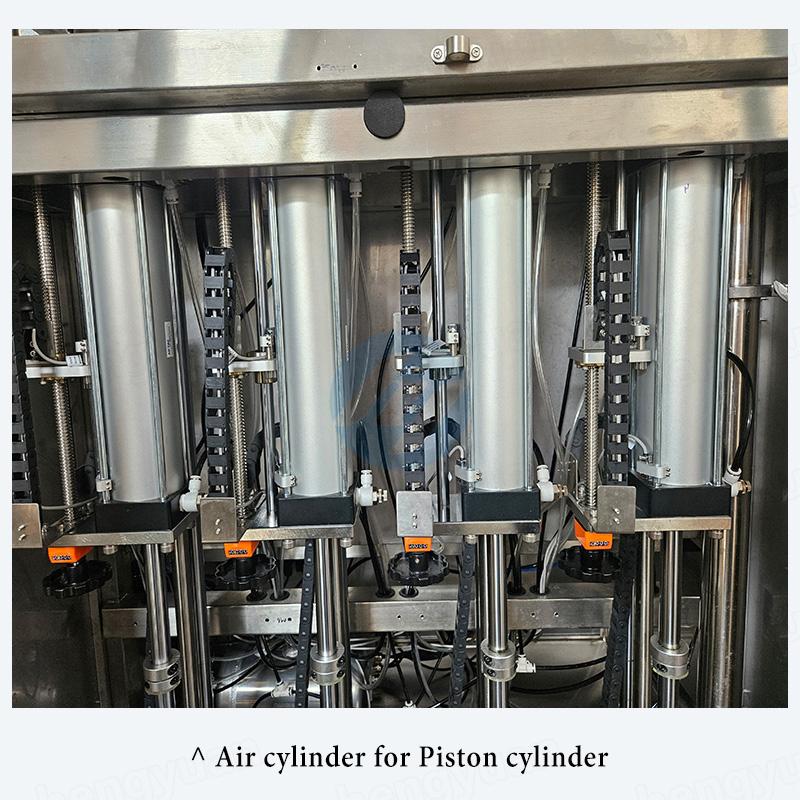

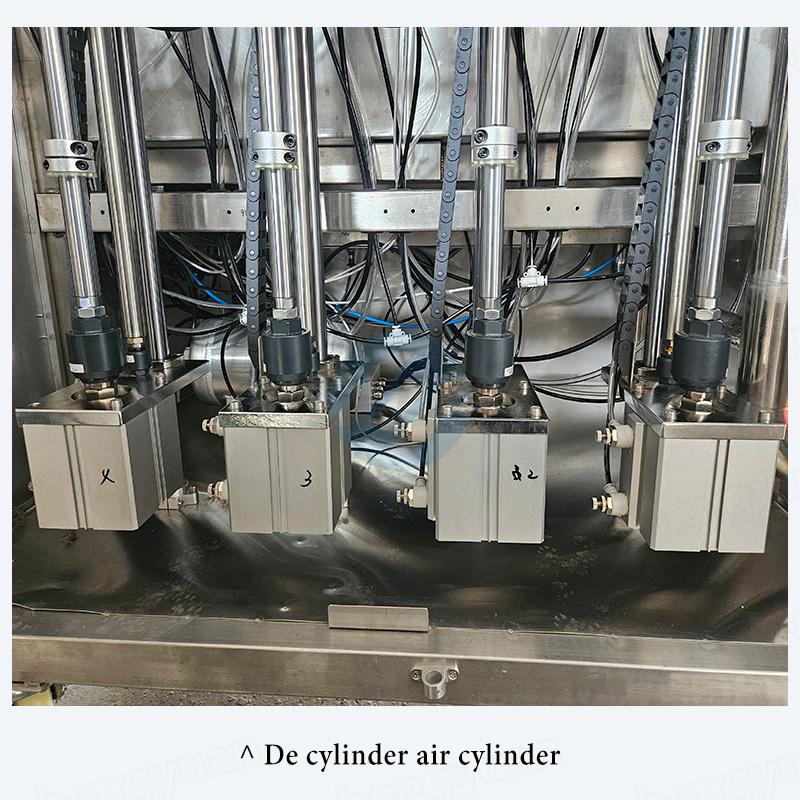

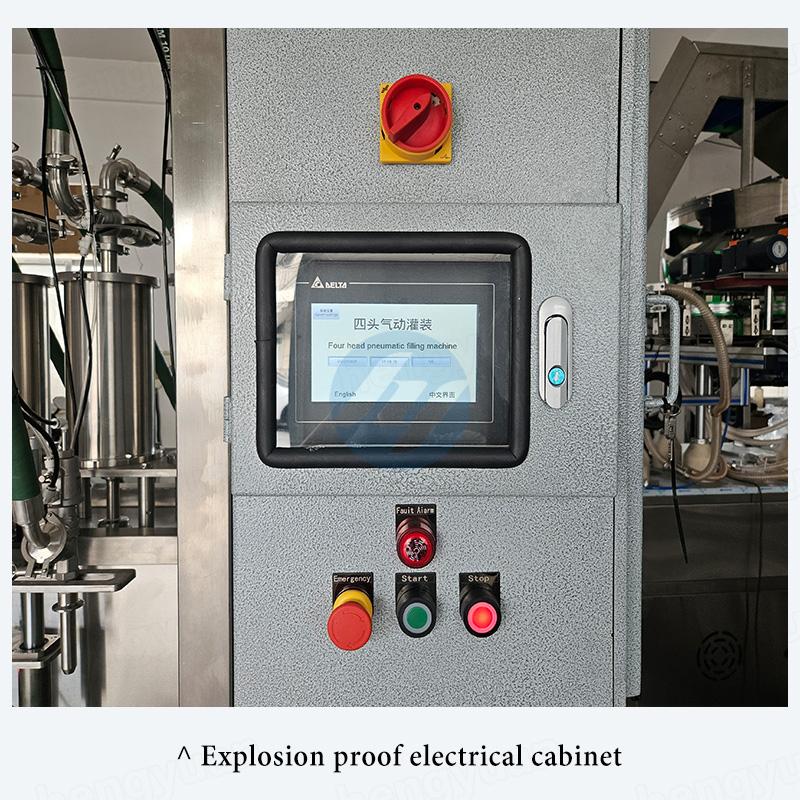

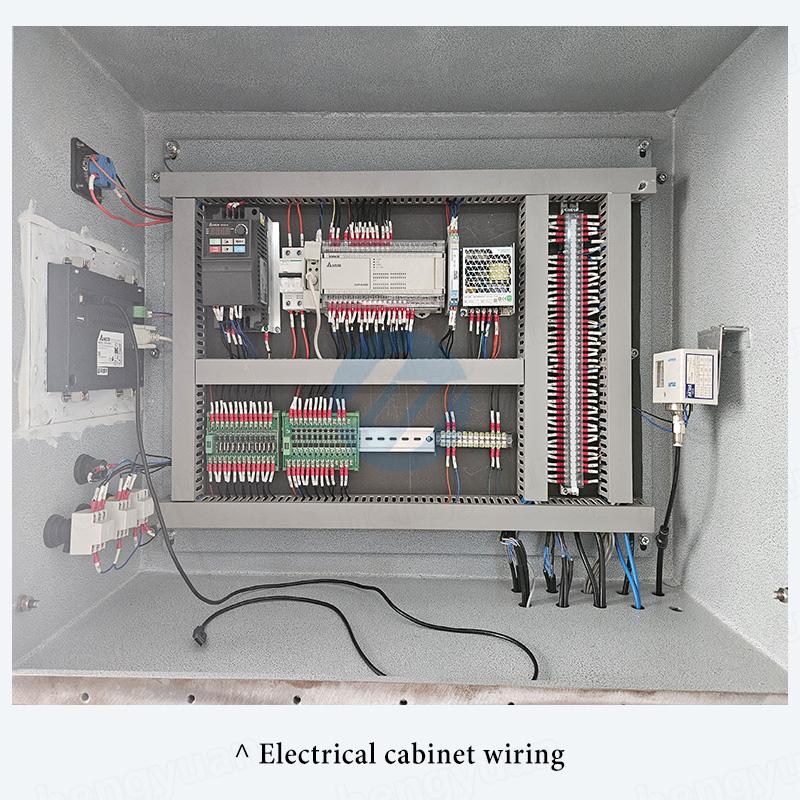

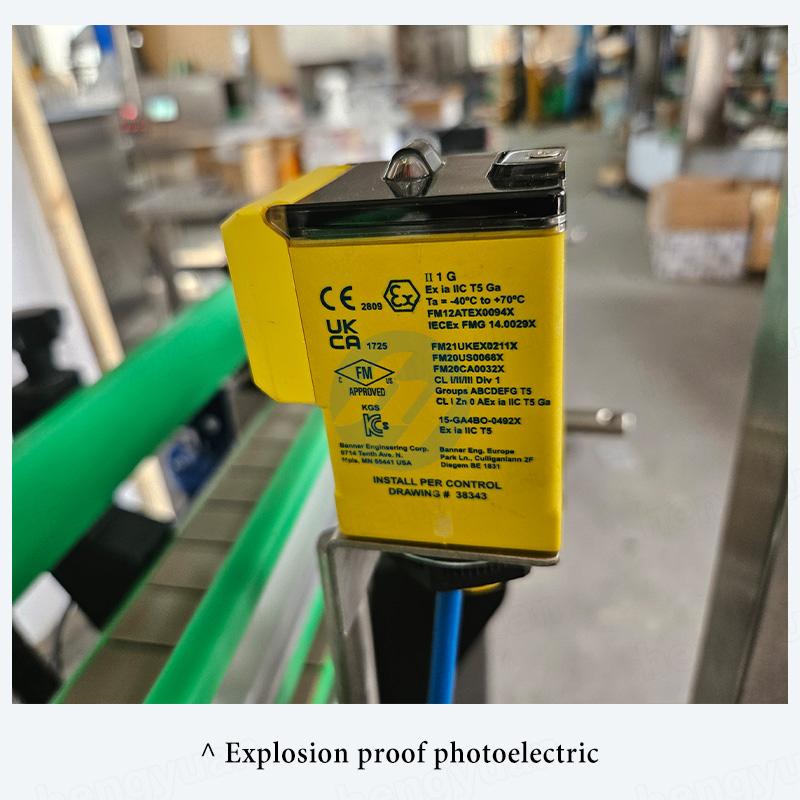

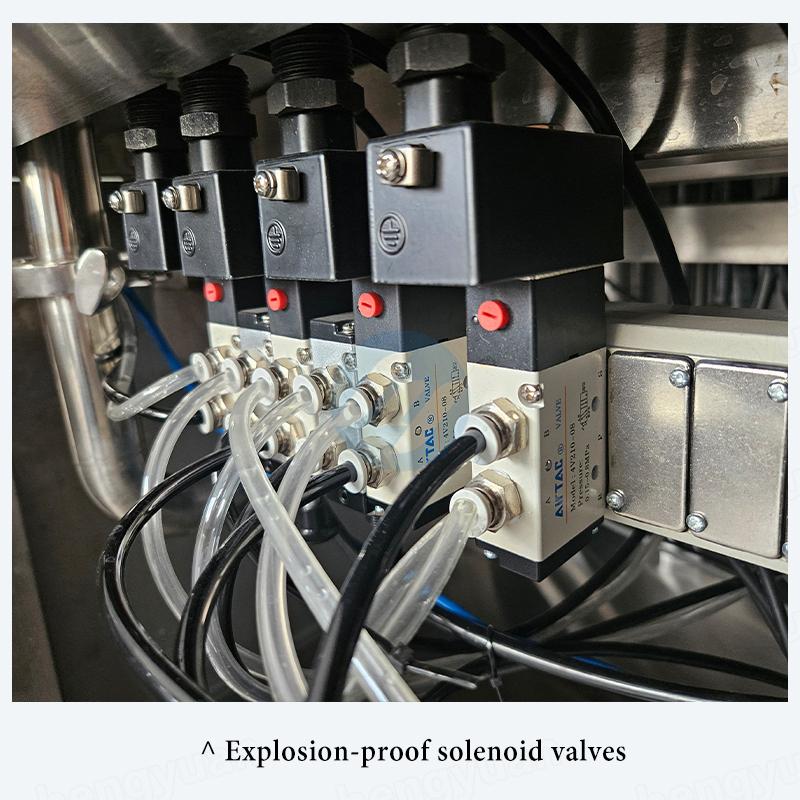

The Automatic Explosion-Proof Pneumatic Piston Filling Machine is an intelligent, fully integrated filling system combining mechanical, electrical, and photoelectric technologies. Designed for hazardous environments, it features explosion-proof components, including an explosion-proof electrical cabinet, photoelectric sensors, control buttons, motor, and solenoid valves, ensuring safe operation with flammable liquids such as paint, isopropyl alcohol, and pesticides. With an adjustable filling range of 1-5L, this machine delivers high precision and efficiency. Equipped with an advanced PLC control system and user-friendly touchscreen interface, it allows for easy parameter adjustments and smooth operation. Additionally, its cycle cleaning design enables fast and efficient cleaning, reducing downtime.

Application

This machine is ideal for industries handling flammable, explosive, or volatile liquids, including:

* Paints & Coatings

* Chemical Solvents (e.g., Isopropyl Alcohol, Acetone)

* Pesticides & Herbicides

* Cosmetic Liquids

* Adhesives & Resins

Technical Parameters

Model

HYPF-5000PS-EX

Filling Head

4 ( other qty 2, 6, 8 can be customized )

Capacity(BPH)

800 based on one gallon

Power(Kw)

0.5

Volume

1l-5L customized

Accuracy

≤±0.5%

Suitable Bottle Size

Customizable

Explosion Proof

Yes

Air supply

0.5-0.7Mpa

Voltage

220V/110V/1P, 50/60Hz, customized globally

Weight

490Kg

Dimension

100x90x190cm

Main Features

1.Explosion-Proof Design – Certified components (electrical cabinet, sensors, motor, valves) ensure safety in hazardous environments.2.Pneumatic Piston Filling – Ensures high accuracy (±0.5%) with minimal dripping.

3.Adjustable Capacity (1-5L) – Easily configurable for different container sizes.

4.PLC + Touchscreen Control – Allows precise adjustments and simple operation.

5.Stainless Steel Construction – Corrosion-resistant and durable for harsh chemicals.

6.Cleaning Cycle System – Reduces manual cleaning time and improves hygiene.

7.Fast & Efficient – Filling speeds up to 10-20 bottles per minute (depending on filling amount).

8.Nozzle Drip-Free Technology – Prevents waste and maintains a clean workspace.