Description

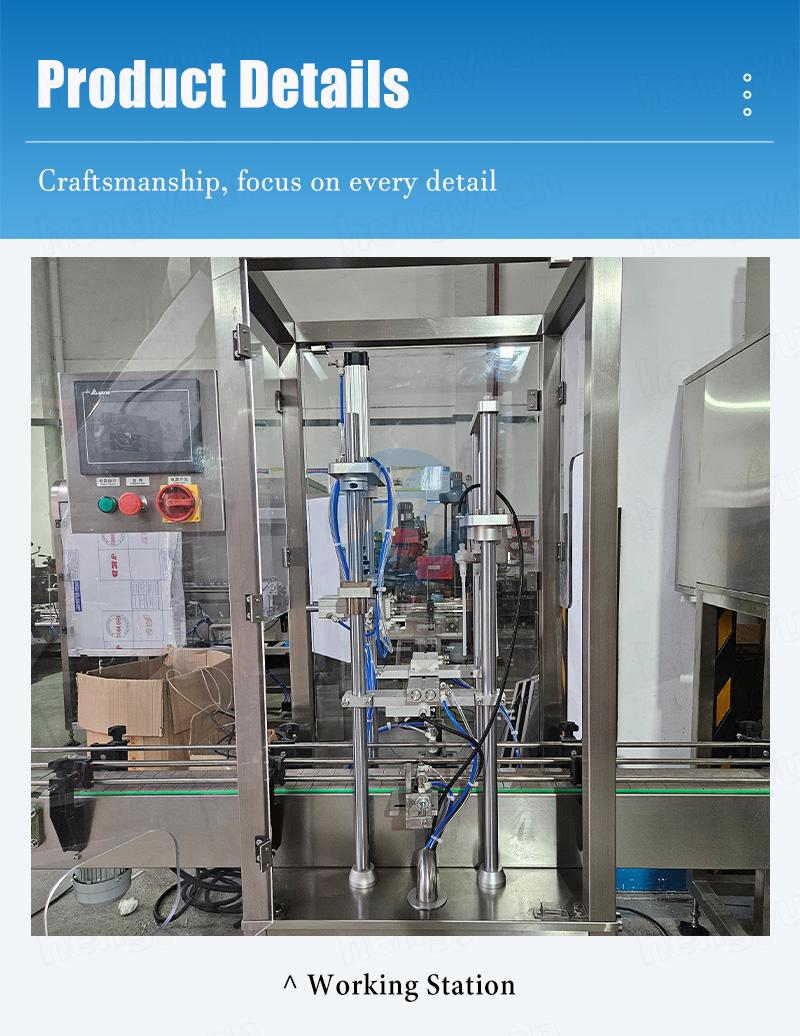

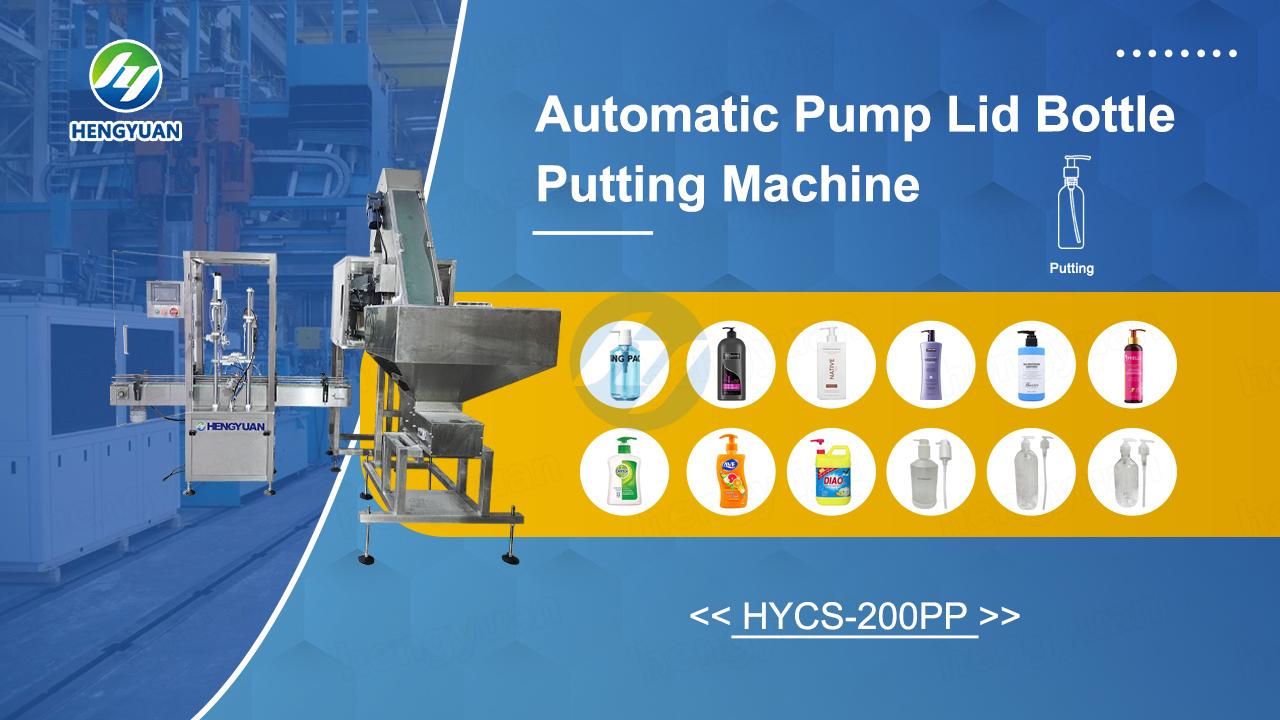

HYCS-200PP Automatic Pump Lid Bottle Putting Machine

Introduction:

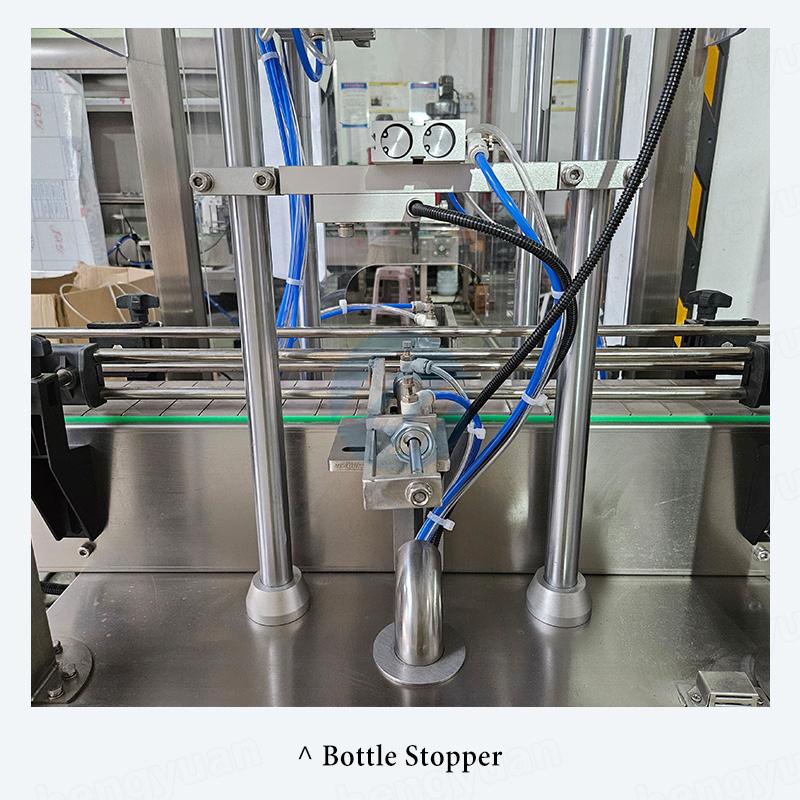

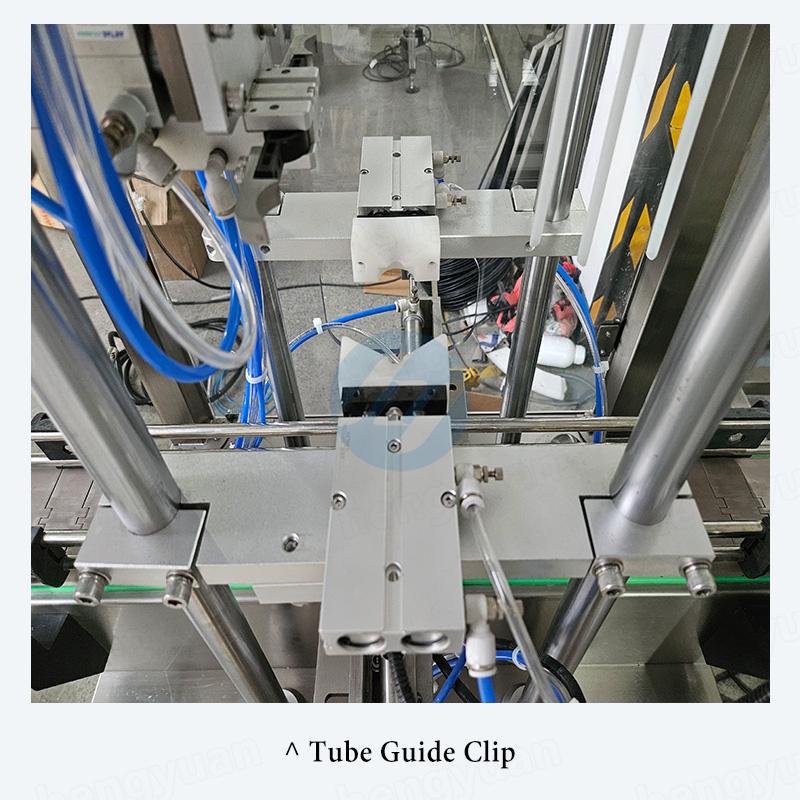

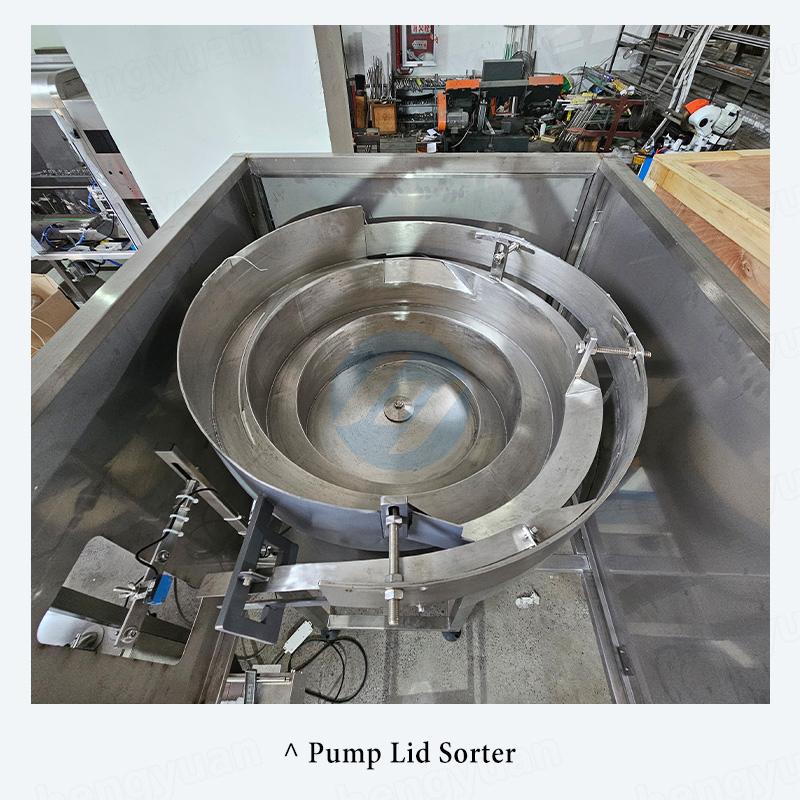

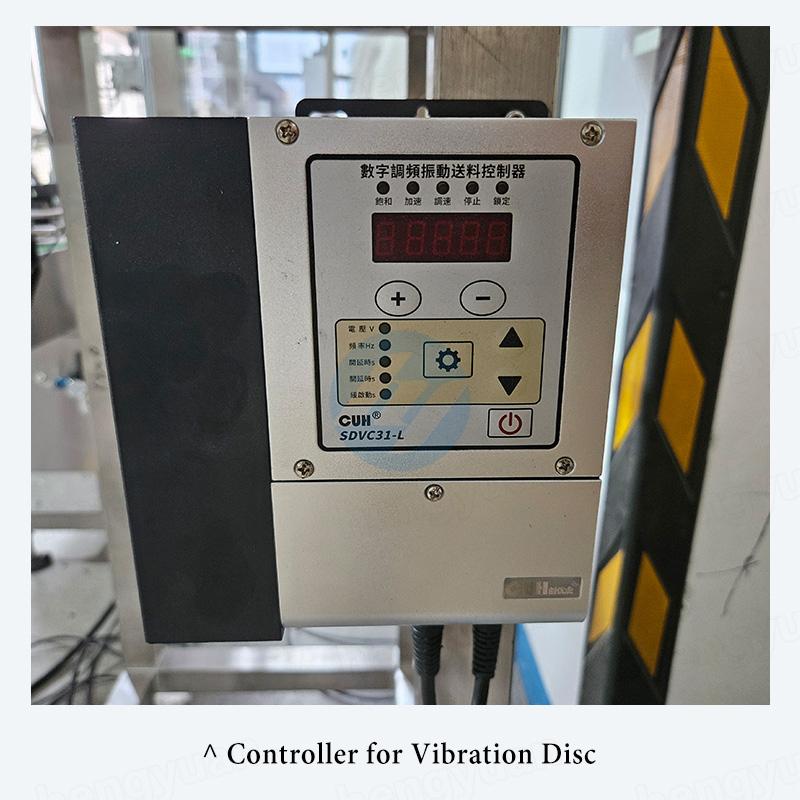

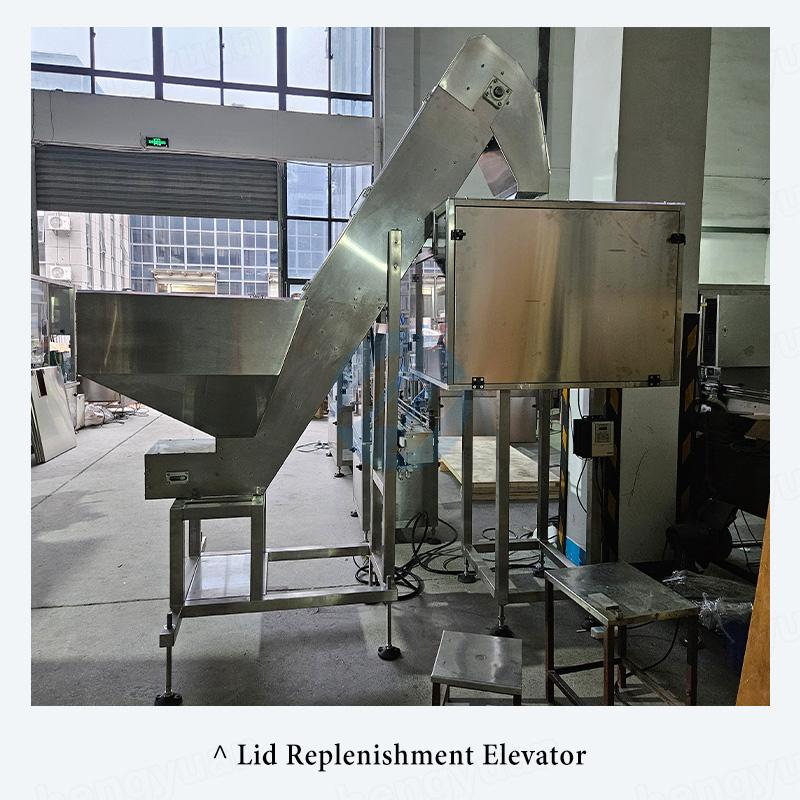

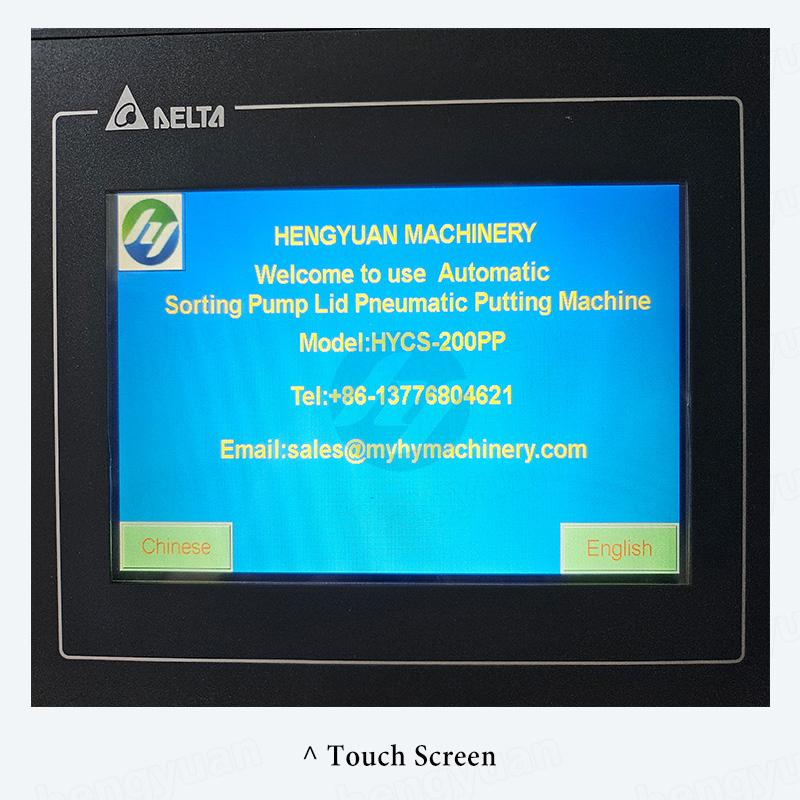

The Automatic Pump Lid Sorting & Placing Machine is an integrated automated system designed for efficient lid handling and placement. Combining mechanical, electrical, and photoelectric technologies with PLC and touchscreen control, it streamlines packaging operations by replacing manual labor and enhancing production efficiency. The system features an automatic lift for bulk lid feeding, a vibratory bowl feeder for precise orientation, a guided chute for smooth transport, and a pneumatic placement unit for accurate lid positioning. An independent power system ensures the conveyor stops during lid placement for optimal synchronization.

Application:

* Cosmetic packaging: pump dispensers, lotion bottles

* Pharmaceutical closures

* Food and beverage container sealing

* Household chemical packaging

2. PLC control with touchscreen interface for easy operation

3. Pneumatic placement unit for precise alignment

4. Independent power system with conveyor synchronization

5. Compact and robust design for continuous operation

Introduction:

The Automatic Pump Lid Sorting & Placing Machine is an integrated automated system designed for efficient lid handling and placement. Combining mechanical, electrical, and photoelectric technologies with PLC and touchscreen control, it streamlines packaging operations by replacing manual labor and enhancing production efficiency. The system features an automatic lift for bulk lid feeding, a vibratory bowl feeder for precise orientation, a guided chute for smooth transport, and a pneumatic placement unit for accurate lid positioning. An independent power system ensures the conveyor stops during lid placement for optimal synchronization.

Application:

* Cosmetic packaging: pump dispensers, lotion bottles

* Pharmaceutical closures

* Food and beverage container sealing

* Household chemical packaging

Technical Parameters

Production Capacity

1200–1600 bottles/hour according to bottle and lid sizes

Applicable Cap

Pump lid

Applicable Bottle Diameter

Ø30 mm to Ø120 mm, special sizes can be customized according to bottle sample

Applicable Bottle Height

80-250mm, special sizes can be customized according to bottle sample

Total Power

1.0Kw

Power Supply

AC220V/110V, Single phase, can be customized globally

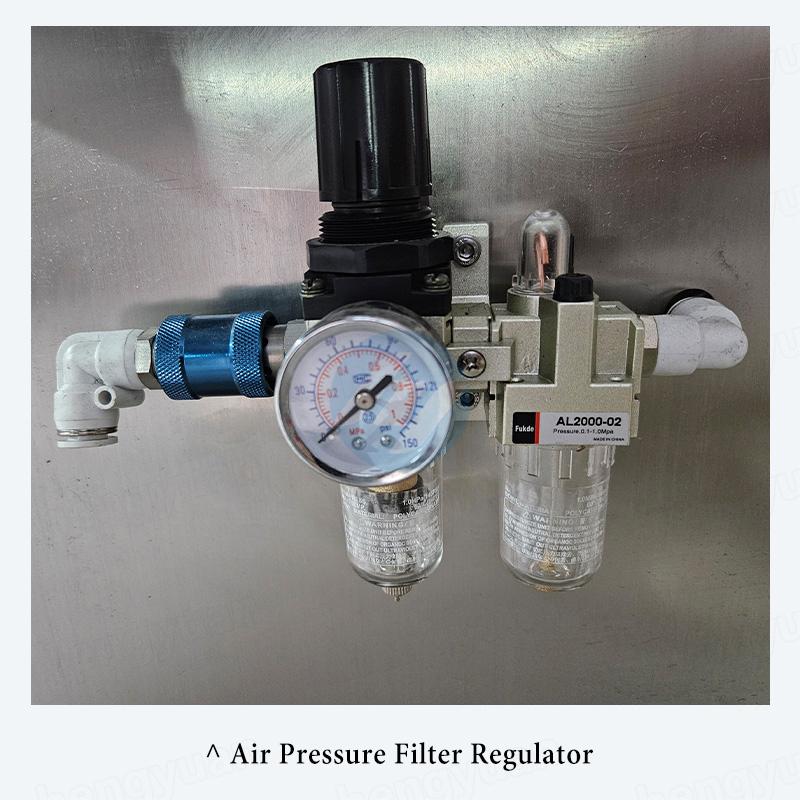

Air Supply

L20 x W150 x H190 cm

Machine Dimensions

390Kg

Weight

0.5-0.7Mpa

Main Features

1. Automated lid feeding, orientation, and pneumatic placement2. PLC control with touchscreen interface for easy operation

3. Pneumatic placement unit for precise alignment

4. Independent power system with conveyor synchronization

5. Compact and robust design for continuous operation

6. Compatible with various lid types and container shapes